Description

304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow 45 Degree 90 Degree 180 Degree Introduction

304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow 30 degree, 45 degree, 60 degree, 90 degree, 180 degree In piping systems, elbows are fittings that change the direction of the pipe. According to the angle, there are 45 degree and 90 degree 180 degree three kinds of the most commonly used, in addition to engineering needs, including 60 ° and other non-normal angle elbow.

Elbow materials are cast iron, stainless steel, alloy steel, malleable iron, carbon steel, non-ferrous metals and plastics. Pipe connection with the way: direct welding (the most common way) flange connection, hot melt connection, fused connection, screw connection and socket connection. In accordance with the production process can be divided into: welding elbow, stamping elbow, pushing the elbow, casting elbow, elbow and so on. Other names: 90-degree elbow, right-angle bend, love and bend and so on.

Commen Grades and Types Of Stainless Steel Butt Weld Elbows:

- Stainless Steel 304 / 304L 30 degree elbow – 304 Stainless Steel Butt Weld Elbow – 304L Stainless Steel Butt weld Elbow:

Stainless Steel 304 / 304L 30 degree elbow is a pipe fitting component designed to alter the direction of a pipeline by 30 degrees, manufactured from ASTM AISI 304 /304L stainless steel. This austenitic alloy contains 18-20% chromium and 8-10.5% nickel, providing excellent corrosion resistance, durability, and formability in moderate environments. The 30° elbow geometry facilitates smooth fluid flow redirection while minimizing pressure drop and turbulence. It complies with ASME B16.9/16.11 standards for dimensions and tolerances, typically produced via cold/hot forming and machining processes, with surface finishes (e.g., electrolytic polishing) optimized for sanitary or industrial applications in chemical, food processing, and HVAC systems.

- Stainless Steel 304 / 304L 45 Degree Elbow – 304 Stainless Steel Elbow – 316L Stainless Steel Elbow:

Stainless Steel 304 / 304L 45 degree elbow is a pipe fitting used to change the direction of fluid flow by 45 degrees in piping systems. Constructed from ASTM AISI 304 / 304L stainless steel (18% chromium, 8% nickel), it offers corrosion resistance, durability, and thermal stability. Manufactured to standards like ASME B16.9, it features a polished surface for reduced contamination risk, making it suitable for food processing, chemical, and pharmaceutical industries. The seamless or welded design ensures leak-proof performance under high-pressure and high-temperature conditions.

- Stainless Steel 304 / 304L 60 Degree Elbow:

Stainless Steel 304 /304L 60 degree elbow is a pipe fitting that redirects fluid flow by 60°, manufactured from austenitic stainless steel (18% Cr, 8% Ni) with ≤0.08% carbon for corrosion resistance and weldability . Its polished internal surface reduces contamination risks, and the design ensures mechanical strength and thermal stability in food, chemical, or pharmaceutical systems requiring durability under acidic or high-temperature conditions.

- Stainless Steel 304 / 304L 90 Degree Elbow:

Stainless Steel 304 / 304L 90 degree elbow is a pipe fitting designed to alter fluid flow direction by 90° in piping systems, constructed from ASTM 304 /304L stainless steel (18% chromium, 8% nickel). As an austenitic stainless steel (300 series), it provides excellent corrosion resistance, high-temperature stability, and mechanical strength, suitable for industries like food processing, chemical, and pharmaceuticals. The elbow is typically manufactured via seamless or welded processes, ensuring leak-proof performance in high-pressure environments, with surface polishing to minimize contamination risks.

- Stainless Steel 304 / 304L 180 Degree Elbow:

Stainless Steel 304 /304L 180 degree elbow is a pipe fitting that alters fluid flow direction by 180°, constructed from austenitic stainless steel (18% chromium, 8% nickel) with ≤0.08% carbon, ensuring corrosion resistance in moderately oxidizing/reducing environments and mechanical durability under high-temperature conditions . Its polished internal surface reduces contamination risks, aligning with applications in food processing, chemical systems, and industrial pipelines requiring hygienic and corrosion-resistant properties. The material’s compliance with SAE specifications and thermal stability (up to 650°C) supports seamless/welded fabrication for pressure-critical installations.

304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow 45 Degree 90 Degree 180 Degree SUPPLIER AND MANUFACTURER IN CHINA WITH HIGH QUALITY AND GOOD PRICE FOR YOUR PROJECT.

- Stainless Steel 316 / 316L 30 Degree Elbow – 316 Stainless Steel Butt Weld Elbow – 316L Stainless Steel Butt weld Elbow

Stainless Steel 316 /316L 30 degree elbow is a pipe fitting engineered to redirect fluid flow by 30°, fabricated from austenitic stainless steel alloyed with molybdenum (18% Cr, 10-14% Ni, 2-3% Mo) to enhance corrosion resistance in chloride-rich or acidic environments and improve high-temperature strength (up to 1200-1300°C) . Its polished internal surface minimizes contamination risks, aligning with hygienic and corrosion-resistant requirements in chemical processing, marine systems, or medical applications . The molybdenum addition further stabilizes the material against pitting and crevice corrosion, ensuring durability in aggressive operational conditions.

- Stainless Steel 316 / 316L 45 Degree Elbow :

Stainless Steel 316 /316L 45 degree elbow is a pipe fitting designed to redirect fluid flow by 45°, manufactured from austenitic stainless steel (18% Cr, 10-14% Ni, 2-3% Mo, ≤0.08% C) for superior corrosion resistance in chloride-rich, acidic, or saline environments . The molybdenum addition enhances pitting and crevice corrosion resistance, while the polished internal surface ensures hygiene and reduced contamination risks in food, marine, or pharmaceutical systems . Its thermal stability (up to 1200-1300°C) and mechanical strength support high-pressure or high-temperature applications, with seamless/welded fabrication complying with ASTM/SAE standards for critical installations.

- Stainless Steel 316 / 316L 60 Degree Elbow:

Stainless Steel 316 / 316L 60 degree elbow is a pipe fitting designed to alter fluid flow direction by 60°, fabricated from austenitic stainless steel (18% Cr, 10-14% Ni, 2-3% Mo) to provide superior corrosion resistance in chloride-rich, acidic, or saline environments and high-temperature stability up to 1200-1300°C . The molybdenum content enhances resistance to pitting and crevice corrosion, ensuring longevity in marine, chemical, and medical applications under harsh conditions . Its polished internal surface minimizes contamination risks, meeting stringent hygiene requirements in food processing and pharmaceutical systems.

- Stainless Steel 316 / 316L 90 Degree Elbow – 316 Stainless Steel Elbow 90° – 316L Stainless Steel 90° Elbow:

Stainless Steel 316 / 316L 90 degree elbow is a pipe fitting designed to redirect fluid flow by 90°, constructed from austenitic stainless steel (18% Cr, 10-14% Ni, 2-3% Mo) for exceptional corrosion resistance in chloride-rich, acidic, or saline environments and thermal stability up to 1200-1300°C . The molybdenum content enhances resistance to pitting and crevice corrosion, ensuring durability in aggressive settings like marine, chemical, or industrial systems . Its polished internal surface minimizes contamination risks, aligning with hygienic standards in food, pharmaceutical, or medical applications . The fitting complies with ASTM/SAE standards for seamless or welded fabrication, supporting high-pressure and high-temperature operational demands.

- Stainless Steel 316 /316L 180 Degree Elbow- 316 Stainless Steel Elbow 180° – 316L Stainless Steel 180° Elbow:

Stainless Steel 316 / 316L 180 degree elbow is a pipe fitting designed to reverse fluid flow direction by 180°, manufactured from austenitic stainless steel (18% Cr, 10-14% Ni, 2-3% Mo) for superior corrosion resistance in chloride-rich, acidic, or high-temperature environments (up to 1200-1300°C) . The molybdenum content enhances resistance to pitting and crevice corrosion, ensuring reliability in aggressive applications like chemical processing, marine systems, or industrial pipelines . Its smooth internal surface minimizes contamination risks, meeting hygienic standards in food, pharmaceutical, and medical industries. The fitting complies with ASTM/SAE specifications for seamless or welded fabrication, supporting high-pressure and high-temperature operational requirements.

304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow 45 Degree 90 Degree 180 Degree SUPPLIER AND MANUFACTURER IN CHINA WITH HIGH QUALITY AND GOOD PRICE FOR YOUR PROJECT.

- Stainless Steel 310 / 310S 30 Degree Elbow – 310 Stainless Steel Butt Weld Elbow – 310S Stainless Steel Butt weld Elbow:

Stainless Steel 310 /310S 30 degree elbow is a pipe fitting designed to alter fluid flow direction by 30°, fabricated from austenitic stainless steel (24-26% Cr, 19-22% Ni) for exceptional high-temperature resistance (up to 1150°C) and oxidation/corrosion resistance in extreme environments like furnaces, heat treatment systems, or power generation. The elevated chromium and nickel content ensures stability under cyclic thermal stress, while its smooth internal surface minimizes turbulence and contamination risks, aligning with applications requiring precise flow redirection in confined spaces. Compliant with ASTM/ASME standards, it supports welded or seamless fabrication for high-pressure, high-temperature systems demanding durability and structural integrity

- Stainless Steel 310 / 310S 45 Degree Elbow – 310S Stainless Steel Elbow 45° – 310 Stainless Steel 45° Elbow:

Stainless Steel 310 / 310S 45-degree elbow is a pipe fitting designed to redirect fluid flow by 45°, constructed from austenitic stainless steel (24-26% Cr, 19-22% Ni) to withstand extreme temperatures (up to 1150°C) and resist oxidation, carburization, and sulfidation in high-heat industrial applications such as furnace exhausts or thermal processing systems. Its elevated chromium and nickel composition ensures structural stability under cyclic thermal stress and corrosive environments. The smooth internal surface minimizes flow turbulence and contamination risks, supporting precision flow control in constrained layouts. Compliant with ASTM/ASME standards, it facilitates welded or seamless integration into high-temperature, high-pressure piping networks requiring corrosion resistance and mechanical durability.

- Stainless Steel 310 / 310S 60 Degree Elbow:

Stainless Steel 310 / 310S 60 degree elbow is a pipe fitting engineered to alter fluid flow direction by 60°, fabricated from austenitic stainless steel (24-26% Cr, 19-22% Ni) for superior resistance to oxidation, carburization, and thermal deformation in high-temperature industrial applications such as furnace systems or heat exchangers. Its high chromium and nickel content ensures stability under cyclic thermal stress (up to 1150°C) and corrosive conditions. The smooth internal curvature minimizes flow turbulence and contamination risks, supporting precision flow management in complex layouts. Compliant with ASTM/ASME standards, it integrates seamlessly into high-pressure, high-temperature piping networks requiring corrosion resistance and mechanical durability.

- Stainless Steel 310 / 310S 90 Degree Elbow- 310 Stainless Steel Elbow 90° – 310S Stainless Steel 90° Elbow:

Stainless Steel 310 / 310S 90 degree elbow is a pipe fitting engineered to change fluid flow direction by 90°, fabricated from austenitic stainless steel containing chromium (24-26%) and nickel (19-22%) for exceptional resistance to oxidation, carburization, and corrosion in high-temperature environments such as industrial furnaces or chemical processing systems. Its alloy composition ensures structural stability under cyclic thermal stress (up to 1150°C) and compatibility with ASTM/ASME standards for mechanical durability in high-pressure applications. The smooth internal curvature minimizes turbulence and pressure drop, facilitating efficient flow control in constrained piping layouts.

- Stainless Steel 310 / 310S 180 Degree Elbow – 310 Stainless Steel Elbow 180° – 310S Stainless Steel 180° Elbow:

Stainless Steel 310 / 310S 180 degree elbow is a U-shaped pipe fitting designed to reverse fluid flow direction completely (180°), fabricated from austenitic stainless steel containing chromium (24-26%) and nickel (19-22%) for superior resistance to oxidation, carburization, and sulfidation in extreme-temperature industrial environments (up to 1150°C) such as furnace exhaust loops or chemical processing units. Its alloy composition ensures mechanical stability under repeated thermal cycling and corrosive media exposure. The smooth internal curvature minimizes turbulence and particulate buildup, maintaining flow efficiency in high-temperature piping systems requiring strict directional control. Compliant with ASTM/ASME standards, it supports welded or threaded connections in configurations demanding corrosion resistance and thermal stress resilience.

Note: The “L” is Low Carbon In The Grades of 304L and 316L, The “S” in 310S stands for ”Special”, designating a modified version of the standard 310 stainless steel alloy with reduced carbon content (≤0.08%).

304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow 45 Degree 90 Degree 180 Degree SUPPLIER AND MANUFACTURER IN CHINA WITH HIGH QUALITY AND GOOD PRICE FOR YOUR PROJECT.

Kcm Special Steel, 304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow 45 degree 90 degree 180 degree related products:

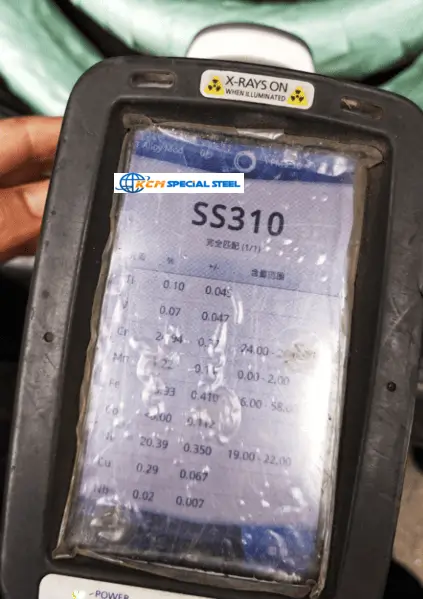

- Stainless Steel Butt Weld Elbow meterial Grade:201, 202, 301, 304, 304L, 310S, 316, 316L, 316Ti, 317, 317L, 321, 347,904L, Dual Grade 304/304L, 316/316L, Duplex Stainless Steel S32304 / 2304, S31803 / 2205, S32750 / 2507 , S32760 Monel400 Inconel600 Incoloy800 Alloy20 Alloy28 Nickel Alloy etc.

- Stainless Steel Elbow Manufacturing Standard:

CHINA GN12459HGJ514-87 SHJ408-90 USA ASTM A 403, ANSI B16.9, ANSI B16.28, ANSI B 16.11, ASTM A815, ANSI B 36.10 JAPAN JIS B 2311, JIS B 2312, JIS B 2313 GERMANY DIN 2605, DIN 2606, DIN 2615 EUROPE EN10253-2 - Stainless Steel Butt Weld Elbow Types: 1>30 degree, 45 degree, 60 degree, 90 degree, 180 degree. 2> stainless steel seamless elbow and stainless steel welded elbow

- Stainless Steel Butt Weld Elbow in stock a part of sizes,non standard size can also arrange new production.

Dimensions for ASME/ANSI Standards Unit:mm B16.9 B16.28 B36.10 A403 A815 Nominal pipe Size(NPS) Outside Diameter Nominal Wall Thickness Sch5s SCH10S Sch20 Sch30 Sch40 STD Sch80 XS Sch160 XXS 8 1/4 13.7 0.54 – 1.65 – 1.85 2.24 2.24 3.02 3.02 – – 10 3/8 17.1 0.675 – 1.65 – 1.85 2.31 2.31 3.20 3.20 – – 15 1/2 21.3 0.84 1.65 2.11 – 2.41 2.77 2.77 3.73 3.73 4.78 7.47 20 3/4 26.7 1.05 1.65 2.11 – 2.41 2.87 2.87 3.91 3.91 5.56 7.82 25 1 33.4 1.32 1.65 2.77 – 2.90 3.38 3.38 4.55 4.55 6.35 9.09 32 1.1/4 42.2 1.66 1.65 2.77 – 2.97 3.56 3.56 4.85 4.85 6.35 9.70 40 1.1/2 48.3 1.90 1.65 2.77 – 3.18 3.68 3.68 5.08 5.08 7.14 10.15 50 2 60.3 2.38 1.65 2.77 – 3.18 3.91 3.91 5.54 5.54 8.74 11.07 65 2.1/2 73.0 2.88 2.11 3.05 – 4.78 5.16 5.16 7.01 7.01 9.53 14.02 80 3 88.9 3.50 2.11 3.05 – 4.78 5.49 5.49 7.62 7.62 11.13 15.24 90 3.1/2 101.6 4.00 2.11 3.05 – 4.78 5.74 5.74 8.08 8.08 – – 100 4 114.3 4.50 2.11 3.05 – 4.78 6.02 6.02 8.56 8.56 13.49 17.12 125 5 141.3 5.56 2.77 3.40 – – 6.55 6.55 9.53 9.53 15.88 19.05 150 6 168.3 6.62 2.77 3.40 – – 7.11 7.11 10.97 10.97 18.26 21.96 200 8 219.1 8.62 2.77 3.76 6.35 7.04 8.18 8.18 12.70 12.70 23.01 22.23 250 10 273.0 10.75 3.40 4.19 6.35 7.80 9.27 9.27 15.09 12.70 28.58 25.40 300 12 323.8 12.75 3.96 4.57 6.35 8.38 10.13 9.53 17.48 12.70 33.32 25.40 350 14 355.6 14 3.96 4.78 7.92 9.53 11.13 9.53 19.05 12.70 35.71 – 400 16 406.4 16 4.19 4.78 7.92 9.53 12.70 9.53 21.44 12.70 40.49 – 450 18 457 18 4.19 4.78 7.92 11.13 14.27 9.53 23.83 12.70 45.24 – 500 10 508 20 4.78 5.54 9.53 12.70 15.09 9.53 26.19 12.70 50.01 – 550 22 559 22 4.78 5.54 9.53 12.70 – 9.53 28.58 12.70 53.98 – 600 24 610 24 5.54 6.35 9.53 14.27 17.48 9.53 30.96 12.70 59.54 – 650 *26 660 26 – – – – – 9.53 – 12.70 – – 700 *28 711 28 – – – – – 9.53 – 12.70 – – 750 *30 762 30 – – – – – 9.53 – 12.70 – – 800 *32 813 32 – – – – – 9.53 – 12.70 – –

304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow 45 degree 90 degree 180 degree Technical Requirement :

1, the majority of 304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow 45 degree 90 degree 180 degree for welding, in order to improve the quality of welding, the end of the car into a groove, leaving a certain angle, with a certain edge, this one is also more stringent requirements, how thick edge, how much angle and deviation The scope of the provisions.

Surface quality and mechanical properties are basically the same as for pipes. For welding convenience, the pipe is the same type of steel as the pipe to be connected.

2, that is, all the 304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow have to go through surface treatment, the inner and outer surface of the oxide coating by shot peening spray, and then coated with anti-corrosion paint. This is for export needs. Moreover, it is also necessary to do the work in this area in order to facilitate the transportation and prevent rust oxidation in China.

3, that is, the packaging requirements For small tube, such as exports, you need to do wooden boxes, about 1 cubic meter, provided that the number of elbows in this box can not exceed about one ton, the standard allows the suit, However, the total weight of the general can not exceed 1 ton.

For the large y will have a single package, such as 24 ” must be a single package. The other is the package mark, mark is to indicate the size, steel, batch number, trademark and other manufacturers.

How to maintain the 304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow 45 degree 90 degree 180 degree ?

1, Long-term storage of 304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow 45 degree 90 degree 180 degree , should be checked on schedule, often on the exposed surface to be kept clean, remove dirt, neatly stored indoors in a dry place, non-stacking or open storage.

Always keep the stainless steel Butt weld elbows dry and ventilated, the holder clean and tidy, stored in accordance with the exact method of storage.

2, the installation, 304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow 45 degree 90 degree 180 degree can be connected directly by the device installed in the pipeline, according to the use of the installation location. Under normal circumstances, can be installed in any position on the pipeline, but to facilitate the test of operation, pay attention to the flow of media until the end of the vertical stainless steel Butt Weld elbow valve should flow upward, stainless steel butt weld elbow can only be installed horizontally.

Stainless steel elbow in the installation should pay attention to sealing, to prevent the emergence of leakage, affecting the normal operation of the pipeline.

3, 304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow 45 degree 90 degree 180 degree ball valve, globe valve, gate valve use, only for full open or fully closed, do not agree to do to adjust the flow to avoid erosion of the sealing surface, accelerated wear and tear.

Gate valve and the thread shut-off valve within the inverted seal device, the hand wheel screwed to the top position, you can prevent the media leak from the packing.

4, 304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow 45 degree 90 degree 180 degree hand wheel, do not use the lever or other tools, so as to avoid damage to the valve. Handwheel clockwise closed, on the contrary is open. Sub-ah use justice, to ensure accurate use of methods and means.

5, 304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow 45 degree 90 degree 180 degree valve packing gland bolts should be tightened evenly, should not be pressed into a crooked state, so as to avoid bumps hinder stem movement or cause leakage.

6, 304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow 45 degree 90 degree 180 degree in the use of the process, should always be kept clean, the transmission screw lubrication must be regular, found that failure should be immediately discontinued to find out the reasons to clear the fault.

Where to Buy 304 / 304L, 316 / 316L, 310 / 310S Stainless Steel Butt Weld Elbow 45 ° 90 ° 180 ° ?

Company name:Kcm Special Steel Co.,Ltd

Add:Yongzhong Street Longwan Area Wenzhou City Zhejiang Provice, China

Website:https://www.duplexstainlesssteelpipes.com

Contact: Mr. Bob Lee

Skype:bobo.lee2

Email:kcmspecialsteel@outlook.com