KCMSS: Delivering Excellence in SUPER DUPLEX PIPE UNS S32750/2507 To Singapore for Offshore & Marine Solutions

1. Introduction: SUPER DUPLEX PIPE UNS S32750/2507 in Offshore Engineering

SUPER DUPLEX PIPE UNS S32750 (also known as SUPER DUPLEX 2507 PIPE) is a critical material for offshore and marine applications due to its exceptional resistance to chloride-induced stress corrosion cracking (SCC), pitting, and crevice corrosion13. Its dual-phase microstructure (austenite and ferrite) ensures high mechanical strength (≥800 MPa tensile strength) and durability in harsh environments such as seawater, subsea pipelines, and high-pressure hydraulic systems.

For Offshore & Marine Solution (Singapore) Pte Ltd, which specializes in subsea infrastructure, SUPER DUPLEX 2507 PIPE provides unmatched reliability for:

- Subsea umbilicals and control systems

- High-pressure risers and flowlines

- Seawater cooling and desalination systems.

2. Technical Specifications: ASTM A790 Seamless Super Duplex Pipe 2507

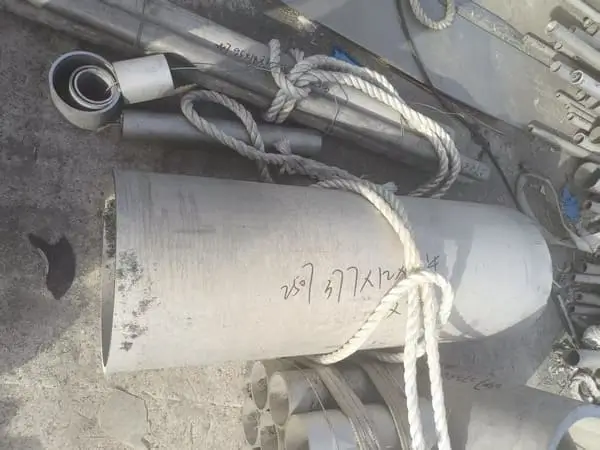

The ASTM A790 standard governs the production of seamless SUPER DUPLEX 2507 PIPES, ensuring compliance with rigorous mechanical and chemical requirements. Below are the dimensions supplied to the Singapore client:

| Parameter | Value |

|---|---|

| Outer Diameter (OD) | 377 mm |

| Wall Thickness | 12 mm / 14 mm |

| Length | 1000 mm (cut-to-length) |

Key Material Properties:

- Density: 7.8 g/cm³ (comparable to DUPLEX STAINLESS STEEL PIPE 2205 but with superior strength).

- PREN (Pitting Resistance Equivalent Number): >40, outperforming 2205 DUPLEX PIPE (PREN ~35).

- Corrosion Resistance: Optimized for chloride-rich marine environments.

3. KCMSS: A Trusted SUPER DUPLEX PIPE SUPPLIER

KCMSS has solidified its position as a leading SUPER DUPLEX PIPE SUPPLIER through:

3.1 Rapid Order Processing & Logistics

- 11:00 AM: Received T/T payment for two SUPER DUPLEX 2507 PIPES (377mm×12mm/14mm×1000mm).

- 1:45 PM: Payment verified; precision cutting and quality checks completed.

- 4:00 PM: Pipes dispatched via express courier, arriving in Singapore within 48 hours.

This efficiency minimizes downtime for clients like Offshore & Marine Solution (Singapore), where project delays can incur significant costs.

3.2 Cut-to-Length Precision

KCMSS’s advanced cutting services ensure:

- Tolerance: ±1mm accuracy for seamless integration into subsea systems.

- Surface Finish: Bright annealing eliminates oxidation, preserving corrosion resistance.

- Cost Savings: Reduced material waste and on-site modification time.

3.3 Large Inventory for Urgent Needs

With SUPER DUPLEX PIPE UNS S32750/2507 readily available in dimensions such as 377mm×12mm/14mm, KCMSS eliminates lead times for critical offshore projects.

Super Duplex Pipe UNS S32750/2507 Cut to Length For Singapore Client Video

4. Case Study: Offshore & Marine Solution (Singapore) Project

Client Requirements:

- Two SUPER DUPLEX 2507 PIPES for a subsea hydraulic control system.

- Compliance with ASTM A790 and NACE MR0175 standards for sour service environments.

KCMSS’s Solution:

- Material Selection: 377mm×14mm pipes chosen for optimal pressure resistance (300-bar capacity).

- Certification: Provided EN 10204 3.1 mill test reports validating chemical composition and mechanical properties13.

- Delivery: Achieved same-day dispatch, ensuring project timelines were met.

Outcome:

The client reported zero defects during installation, praising the pipes’ dimensional accuracy and corrosion-resistant surface finish.

5.KCMSS: Your Trusted Partner for Immediate Access to SUPER DUPLEX PIPE UNS S32750 & DUPLEX 2205 Pipes

In industries where downtime is not an option, KCMSS stands out as a global leader in supplying SUPER DUPLEX PIPE UNS S32750/2507 and DUPLEX 2205 PIPES (UNS S31803/S32205) from its extensive ready stock. With a commitment to rapid delivery and uncompromised quality, KCMSS ensures clients worldwide can address urgent project needs without delays.

Key Advantages of KCMSS’s Inventory

1. Immediate Availability for Critical Applications

KCMSS maintains large quantities of SUPER DUPLEX PIPE UNS S32750 and DUPLEX 2205 PIPES in standardized and custom specifications, including:

- Outer Diameter (OD): 10mm to 500mm (catering to offshore, oil/gas, and chemical industries).

- Wall Thickness (WT): 2mm to 30mm (optimized for high-pressure and corrosive environments).

- Lengths: Standard 6m, with cut-to-length services for precision sizing (±1mm tolerance).

This readiness eliminates production lead times, enabling same-day dispatch for urgent orders.

2. Compliance with Rigorous Standards

All pipes meet ASTM A790/A789/A928, NACE MR0175/ISO 15156, and EN 10204 3.1 certifications, ensuring:

- Resistance to pitting, crevice corrosion, and stress corrosion cracking (PREN ≥40 for SUPER DUPLEX 2507).

- Suitability for sour service (H₂S environments) and chloride-rich applications (e.g., seawater cooling systems).

- Traceability via mill test reports validating chemical composition and mechanical properties.

3. Material Excellence

| Feature | SUPER DUPLEX 2507 | DUPLEX 2205 |

|---|---|---|

| Corrosion Resistance | Superior (25% Cr, 4% Mo, 7% Ni) | High (22% Cr, 3% Mo, 5% Ni) |

| Yield Strength | ≥550 MPa | ≥450 MPa |

| Cost Efficiency | Ideal for extreme environments | Budget-friendly for moderate uses |

Industries Served with Speed & Precision

KCMSS’s stocked pipes are critical for:

- Oil & Gas: Subsea pipelines, hydraulic control systems, and risers requiring SUPER DUPLEX 2507’s resistance to high-pressure sour gas.

- Chemical Processing: DUPLEX 2205 pipes for acid storage tanks and heat exchangers.

- Desalination & Marine: SUPER DUPLEX 2507 in seawater reverse osmosis (SWRO) systems.

- Renewable Energy: Hydrogen transport pipelines and offshore wind farm cooling systems.

Why Choose KCMSS for Urgent Orders?

- Global Logistics Network: Supply Asia, Europe, and the Americas ensure 48-hour delivery to most regions.

- Value-Added Services: Precision cutting, bevelling, and surface treatment (bright annealing, pickling) to meet installation-ready demands.

- 24/7 Support: Dedicated technical teams assist with material selection, compliance, and logistics.

Conclusion

For projects that cannot afford delays, KCMSS provides instant access to SUPER DUPLEX PIPE UNS S32750/2507 and DUPLEX 2205 PIPES, backed by rigorous quality control and agile delivery. Whether replacing failed components or accelerating new installations, KCMSS’s ready stock and expertise ensure operational continuity in the most demanding environments.

6. SUPER DUPLEX 2507 vs. DUPLEX STAINLESS STEEL PIPE 2205

While both alloys serve corrosive environments, SUPER DUPLEX 2507 is preferred for offshore applications due to:

| Parameter | SUPER DUPLEX 2507 | 2205 DUPLEX PIPE |

|---|---|---|

| Chromium (Cr) | 25% | 22% |

| Molybdenum (Mo) | 4% | 3% |

| PREN | >40 | ~35 |

| Yield Strength | ≥550 MPa | ≥450 MPa |

The higher PREN and strength of SUPER DUPLEX 2507 make it ideal for seawater exposure, whereas 2205 DUPLEX PIPE is typically used in less aggressive environments like chemical processing tanks.

7. Future Applications in Renewable Energy

SUPER DUPLEX PIPE UNS S32750 is increasingly adopted in:

- Offshore Wind Farms: Foundations and seawater cooling systems.

- Hydrogen Transport: Pipelines for green hydrogen4.

- Carbon Capture: High-pressure CO₂ injection systems5.

Suppliers like KCMSS are pivotal in supporting these innovations through agile logistics and technical expertise

8. Why Clients Choose KCMSS

- Technical Expertise: Decades of experience in metallurgy and offshore engineering.

- Global Reach: Supply to Asia, Europe, and North America for fast delivery.

- Sustainability: Eco-friendly production and recyclable materials.

- Win-Win Partnerships: Aligning with client goals for long-term collaboration.

9. Conclusion

For Offshore & Marine Solution (Singapore) Pte Ltd, SUPER DUPLEX PIPE UNS S32750/2507 is a strategic asset ensuring operational safety in corrosive subsea environments. KCMSS’s commitment to rapid delivery, precision cutting, and certified quality reinforces its reputation as a trusted SUPER DUPLEX PIPE SUPPLIER. By maintaining large inventories and prioritizing client needs, KCMSS drives innovation and reliability in the global offshore sector