Description

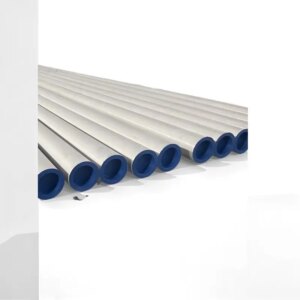

What Is Stainless Steel Square Tube

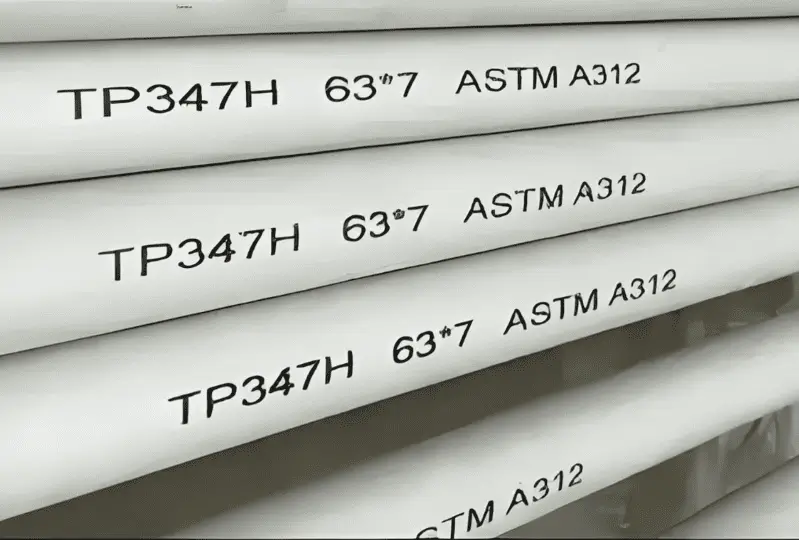

Stainless steel square tube is a hollow structural profile with equal sides and a square cross-section, manufactured from corrosion-resistant alloys (e.g., 304/316) via seamless (ASTM A312) or welded (ASTM A554) processes, complying with ISO 9445/EN 10296-2 standards

Expanded Description:

Stainless steel square tube is a precision-engineered hollow component defined by its geometric uniformity (90° angular cross-section, ±0.1mm dimensional tolerance16) and corrosion-resistant alloys. Key materials include Grade 304 (18% Cr, 8% Ni) and 316 (16% Cr, 10% Ni, 2% Mo), which form a self-repairing chromium oxide layer to resist oxidation, chlorides, and acids16.

Manufacturing Processes

- Seamless Fabrication (ASTM A312):

- Produced via hot extrusion or cold drawing, ideal for high-pressure hydraulic systems or heat exchangers.

- Strict wall thickness tolerances (±5%) and surface roughness ≤0.8µm.

- Welded Fabrication (ASTM A554):

- Formed by roll-forming stainless steel coils followed by laser/TIG welding, cost-effective for architectural frameworks or food-grade conveyor systems.

- Weld strength ≥90% of base material, meeting mechanical requirements per EN 10296-2.

Properties & Specifications

- Mechanical Performance: Tensile strength ranges from 515-860 MPa (Grade 304) to 620-795 MPa (Grade 316), with hardness ≤90 HRB (ISO 9445).

- Corrosion Resistance: Passes ISO 3651-2 intergranular corrosion testing, suitable for marine or chemical environments.

- Surface Finishes: Options include mirror-polished (Ra ≤0.05µm) or brushed (Ra ≤0.4µm), complying with ASTM A1011 standards.

Applications

- Construction: Curtain wall mullions, seismic-resistant frameworks (EN 10296-2).

- Industrial: Heat exchanger tubing (GB/T30059), FDA-compliant food-processing equipment.

- Transportation: Marine exhaust stacks (heat-resistant up to 800°C), rail undercarriage components.

Sustainability & Standards

- Recyclable (100% scrap reuse) and compliant with LEED/BREEAM certifications.

- Globally standardized per ASTM A554 (welded), ASTM A312 (seamless), and ISO 9445 (tolerances).

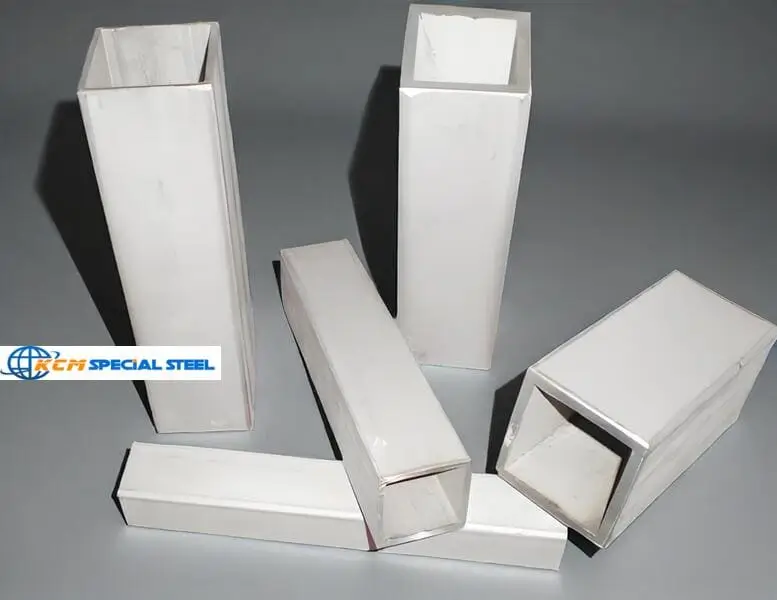

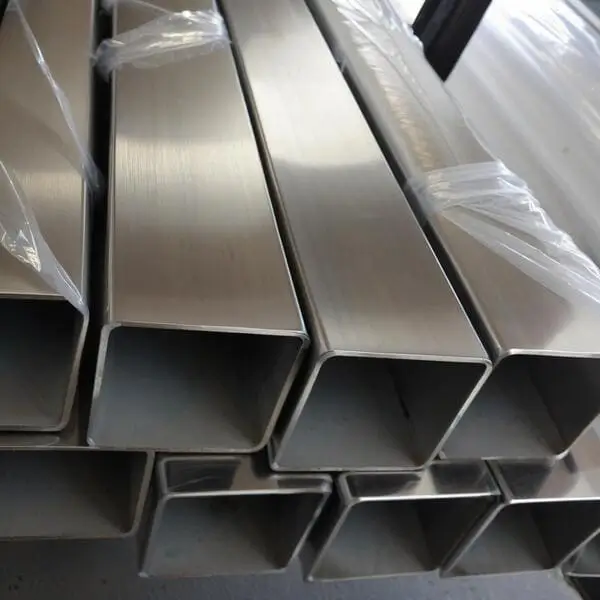

Premium Stainless Steel Square Tubes by KCM Special Steel Co., Ltd: Unmatched Quality for Industrial & Architectural Excellence

KCM Special Steel Co., Ltd delivers high-performance stainless steel square tubes, pipes, and tubing. Explore 304 and 316 grades, competitive pricing, and custom solutions for construction, automotive, and industrial projects.

- Austenitic: 304 (UNS S30400), 316L (UNS S31603), 321 (UNS S32100), 317/317L, 310/310S, 904L/UNS N08904, 316Ti, 347/347H, 304L, 201, 202 .

- Ferritic: 430 (UNS S43000), 409 (UNS S40900) .

- Martensitic: 410 (UNS S41000) .

- Duplex: 2205 (UNS S32205), 2507 (UNS S32750) .

Standards:

- ASTM A312/A312M: Covers seamless/welded austenitic stainless steel tubes for high-temperature service .

- ASTM A269: Specifies seamless/welded austenitic tubes for general applications .

- EN 10216-5: European standard for seamless stainless steel tubes in pressure equipment .

- JIS G3459: Japanese standard for seamless/welded stainless steel tubes

Duplex Steel Square Tubes

Materials:

- Standard Duplex: 2205 (UNS S32205), 2304 (UNS S32304) .

- Super Duplex: 2507 (UNS S32750), 255 (UNS S32550) .

Standards:

- ASTM A789/A789M: Covers seamless/welded duplex tubes for corrosive environments .

- ASTM A240/A240M: Specifies duplex stainless steel plates/sheets (applicable to tubes by analogy) .

- EN 10216-5: Includes duplex grades for pressure applications .

3. Nickel-Based Alloy Square Tubes

Materials:

- Inconel®625 (UNS N06625), Incoloy®800H/HT (UNS N08800), Incoloy®825 (UNS N08825), Inconel®718 (UNS N07718) Inconel®600, Inconel®601,monel®400, Monel®500K

- Alloy20, Alloy28, Alloy31,Nimonic®60/80A

- Precipitation-Hardening Stainless Steel 17-4PH (UNS S17400), 15-5PH (UNS S15500), PH13-8Mo (UNS S13800), 630 (ASTM A564), 631 (17-7PH, UNS S17700), Custom 450 (UNS S45000), Custom 455 (UNS S45500), AM 350 (UNS S35000), AM 355 (UNS S35500)

Standards:

- ASTM B444/B444M: Specifies seamless/welded nickel-chromium-molybdenum alloy tubes (e.g., Inconel 625) .

- ASTM B729/B729M: Covers seamless/welded nickel-iron-chromium alloy tubes (e.g., Incoloy 800)

Square Stainless Steel Tubing And Round Stainless Steel Pipe Manufactured By KCM Special Steel Video

Stainless Steel Square Tube Sizes Available In Stock Or For New Production

1. Common MM Dimensions

Outer Width (mm) | Wall Thickness (mm) | Material Grades | Standards |

|---|---|---|---|

10×10 – 400×400 | 0.4 – 40.0 | Stainless Steel Duplex & Super Duplex Nickel Alloy | ASTM/ASME EN/DIN GB/JIS |

2. DN-Inch Equivalents

DN Size | Inch Equivalent | Common Name |

|---|---|---|

DN15 | ½” | 4 fen (Quarter-inch) |

DN20 | ¾” | 6 fen (Three-quarter inch) |

DN25 | 1″ | 1-inch |

DN32 | 1¼” | 1.25-inch |

DN40 | 1½” | 1.5-inch |

DN50 | 2″ | 2-inch |

DN65 | 2½” | 2.5-inch |

DN80 | 3″ | 3-inch |

DN100 | 4″ | 4-inch |

DN125 | 5″ | 5-inch |

DN150 | 6″ | 6-inch |

DN200 | 8″ | 8-inch |

DN250 | 10″ | 10-inch |

Notes:

DN (Nominal Diameter): Represents the approximate inner diameter of round tubes and is extended to square/rectangular tubes by analogy.

Inch Conversion: 1 inch = 25.4 mm (e.g., ½” ≈ 12.7 mm)

1. Introduction to Stainless Steel Square Tubes

Stainless steel square tubes, also referred to as stainless steel square pipes, square stainless steel tubing, or square stainless steel pipes, are hollow structural profiles with equal side lengths. Renowned for their corrosion resistance, durability, and sleek appearance, these tubes are indispensable in industries ranging from construction to aerospace.

At KCM Special Steel Co., Ltd, we specialize in manufacturing precision-engineered 304 stainless steel square tubes and 316 stainless steel square tubes, tailored to meet rigorous global standards. Our products combine advanced metallurgical techniques with sustainable practices, ensuring reliability even in the most demanding environments.

2. Why Choose KCM’s Stainless Steel Square Tubing?

2.1 Superior Material Grades

304 Stainless Steel Square Tube:

The most widely used austenitic stainless steel, Grade 304 offers exceptional resistance to oxidation, acids, and organic chemicals. With 18% chromium and 8% nickel, it is ideal for:Food processing equipment

Architectural trim and handrails

HVAC systems

General-purpose industrial frameworks

316 Stainless Steel Square Tube:

Enhanced with 2-3% molybdenum, Grade 316 excels in chloride-rich environments, making it the go-to choice for:Marine applications (shipbuilding, offshore platforms)

Pharmaceutical and chemical processing equipment

Coastal architectural structures

Both grades are available in polished, brushed, or mill finishes to suit aesthetic and functional requirements.

2.2 Precision Manufacturing Processes

KCM employs state-of-the-art technology to produce stainless steel square tubing with dimensional accuracy and mechanical consistency:

Cold Drawing: Reduces tube diameter and wall thickness for enhanced strength and surface finish.

Hot Rolling: Ideal for thicker-walled tubes requiring high load-bearing capacity.

Laser Cutting & Welding: Ensures seamless joints and custom lengths (up to 16m).

All tubes comply with ASTM A554, ASTM A312, EN 10296-2, and JIS G3466 standards, backed by ISO 9001:2015 certification.

2.3 Competitive Pricing Strategy

Despite fluctuations in raw material costs, KCM maintains a transparent 304 stainless steel square tube price structure. Factors influencing pricing include:

Nickel and chromium market rates

Customization requests (e.g., perforations, non-standard sizes)

Order volume discounts (5-15% for bulk purchases)

For instance, our 304 stainless steel square tube price starts at USD2.50 per kilogram; for standard sizes, while 316 stainless steel square tubes begin at USD4.20 per kilogram.

3. Applications of Stainless Steel Square Pipes

3.1 Architecture & Construction

Structural Frameworks:

Square stainless steel tubes provide robust support for glass facades, atriums, and rooftop installations. Their corrosion resistance eliminates maintenance costs in humid or coastal areas.

Decorative Elements:

From minimalist stair railings to avant-garde sculptures, polished stainless steel square tubing adds a modern aesthetic to commercial and residential spaces.

3.2 Automotive & Transportation

Exhaust Systems:

316 stainless steel square tubes withstand high temperatures and salt spray, extending vehicle lifespan.

Chassis Components:

Lightweight yet durable square tubes improve fuel efficiency without compromising safety.

3.3 Industrial Machinery

Conveyor Systems:

Stainless steel square pipes resist abrasion and chemical exposure in mining and manufacturing plants.

Hydraulic Cylinders:

Precision tubes ensure leak-free performance in high-pressure environments.

4. 304 vs. 316 Stainless Steel Square Tubes: A Detailed Comparison

Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

Composition | 18% Cr, 8% Ni, 0.08% C | 16% Cr, 10% Ni, 2% Mo, 0.08% C |

Corrosion Resistance | Resists acids, freshwater | Superior in seawater, chlorides |

Temperature Tolerance | Up to 870°C (intermittent) | Up to 800°C (intermittent) |

Typical Applications | Kitchen equipment, roofing | Marine hardware, chemical tanks |

Price Comparison | Lower (304 stainless steel square tube price ≈ 30-40% less) | Higher due to molybdenum content |

5. Advantages of KCM’s Stainless Steel Square Tubing

- Longevity: Withstand harsh weather, UV exposure, and chemical corrosion for decades.

- Eco-Friendly: 100% recyclable, aligning with green building certifications (LEED, BREEAM).

- Customization:

- Sizes: 10x10mm to 150x150mm (wall thickness: 0.5mm to 12mm)

- Finishes: Mirror, hairline, bead-blasted, or powder-coated

- Packaging: Wooden crates or PVC sleeves for international shipping

6. Market Insights & Industry Trends

The global stainless steel square pipe market is projected to grow at a 5.8% CAGR from 2023 to 2030, driven by:

- Infrastructure development in emerging economies

- Rising demand for sustainable construction materials

- Advancements in additive manufacturing (3D-printed tube fittings)

KCM stays ahead by investing in R&D, including:

- AI-driven quality inspection systems

- Low-carbon production techniques

7. How to Order from KCM Special Steel Co., Ltd

- Submit Requirements: Share technical drawings or specifications (grade, size, Length, Quantity).

- Receive a Quote: Includes 304 stainless steel square tube price, lead time (3-21 days), and logistics options.

- Quality Assurance: Third-party testing (SGS, TUV) is acceptble as per clients’ request.

- Global Delivery: FOB/CFR/EXW/CIF terms to major ports in the America, EU,AU, Middle East, Asia And Africa.

8. Customer Success Stories

Case Study 1: A German automotive supplier reduced component failure rates by 60% after switching to KCM’s 316 stainless steel square tubes for brake line assemblies.

Case Study 2: A Dubai skyscraper project saved $200,000 in maintenance costs using our polished square stainless steel tubing for exterior cladding.

9. FAQs About Stainless Steel Square Tubes

Q: What is the maximum length for custom square stainless steel pipes?

A: We offer tubes up to 16 meters; longer lengths can be achieved via welding.

Q: How does KCM ensure corrosion resistance in marine environments?

A: Our 316 stainless steel square tubes undergo passivation to enhance the chromium oxide layer.

Q: Can I order small quantities for prototyping?

A: Yes, we accept MOQs as low as 10 kilograms.

10. Conclusion

KCM Special Steel Co., Ltd redefines excellence in stainless steel square tube manufacturing. Whether you need cost-effective 304 stainless steel square tubes or premium 316 stainless steel square tubes, our solutions blend innovation, durability, and value. Contact us today at [kcmspecialsteel@outlook.com] to discuss your project requirements and receive a competitive quote!