Description

Nickel Alloy INCOLOY 800HT Pipes and Fittings, Tubes: Technical Specifications and Applications

Introduction to INCOLOY® 800HT

INCOLOY® 800HT (UNS N08811) is a high-performance nickel-iron-chromium alloy engineered for extreme temperature and corrosive environments. Renowned for its superior oxidation resistance, creep strength, and thermal stability, it is widely utilized in industries such as petrochemicals, power generation, and aerospace. The alloy’s composition—enhanced with controlled carbon, aluminum, and titanium levels—ensures longevity in applications exceeding 1500°F (816°C). Products like Nickel Alloy 800HT Pipes, Tubes, and Fittings comply with ASTM, ASME, and DIN standards, guaranteeing reliability under high-stress conditions.

Nickel Alloy INCOLOY® 800HT Pipe is an austenitic Ni-Cr-Fe alloy pipe (Ni 30-35%, Cr 19-23%, C 0.06-0.10%) per ASTM B407/B409, optimized for high-temperature (≤1100°C) and high-pressure applications (e.g., nuclear steam pipes, petrochemical cracking furnaces) with enhanced creep resistance.

Nickel Alloy INCOLOY® 800HT Tube is an austenitic Ni-Cr-Fe alloy (Ni 30-35%, Cr 19-23%, C ≤0.10%) conforming to ASTM B407/B409, designed for high-temperature (≤1100°C) and high-pressure applications (e.g., petrochemical cracking furnaces, nuclear systems) with enhanced creep resistance and oxidation/carburization resistance.

Nickel Alloy INCOLOY® 800HT Pipe Fittings are specialized connectors (e.g., elbows, tees, flanges) fabricated from austenitic Ni-Cr-Fe alloy (Ni 30-35%, Cr 19-23%, C 0.06-0.10%) per ASTM B366/B407, designed for critical high-temperature (≤1100°C) and high-pressure systems (petrochemical cracking furnaces, nuclear steam lines) to maintain structural integrity with enhanced creep resistance, oxidation/carburization stability, and corrosion resilience.

Table 1: Global Designations for INCOLOY® 800HT

| Country/Standard | Designation |

|---|---|

| USA (UNS) | N08811 |

| Europe (EN) | 1.4958 |

| Germany (DIN) | W.Nr. 1.4958 |

Nickel Alloy INCOLOY 800HT Pipes and Fittings Supplier and Manufacturer In China, KCM SPECIAL STEEL is selling high quality INCOLOY® 800HT Pipes & Fittings with competitive Price.

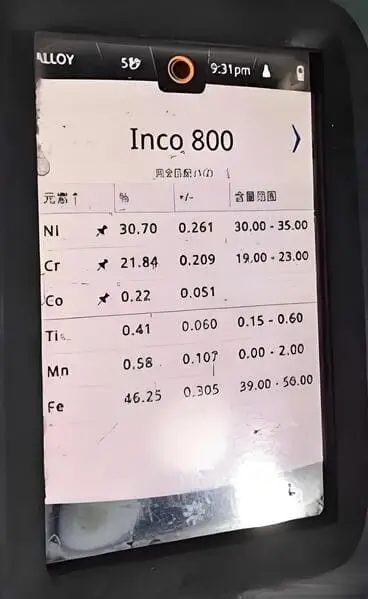

Nickel Alloy INCOLOY 800HT Pipes and Fittings Chemical Composition

The chemical composition of INCOLOY® 800HT is critical to its performance. Key elements include:

- Nickel (30–35%): Enhances ductility and resistance to chloride stress corrosion.

- Chromium (19–23%): Provides oxidation resistance in high-temperature atmospheres.

- Iron (≥39.5%): Forms the alloy’s structural base.

- Carbon (0.06–0.10%), Aluminum (0.15–0.60%), Titanium (0.15–0.60%): Stabilize the microstructure against thermal degradation.

Table 2: Full Chemical Composition of INCOLOY® 800HT(UNS N08811)

| Element | Min (%) | Max (%) | Notes/Remarks |

|---|---|---|---|

| Nickel (Ni) | 30.00 | 35.00 | Enhances ductility and resistance to chloride stress corrosion. |

| Chromium (Cr) | 19.00 | 23.00 | Provides oxidation resistance in high-temperature environments. |

| Iron (Fe) | 39.50 | Balance | Base element ensuring structural integrity. |

| Carbon (C) | 0.06 | 0.10 | Stabilizes microstructure; improves creep resistance. |

| Aluminum (Al) | 0.15 | 0.60 | Enhances high-temperature strength and oxidation resistance. |

| Titanium (Ti) | 0.15 | 0.60 | Stabilizes carbides and prevents phase degradation. |

| Manganese (Mn) | – | 1.50 | Controlled impurity to minimize brittleness. |

| Silicon (Si) | – | 1.00 | Limits impurity content; improves oxidation resistance. |

| Sulfur (S) | – | 0.015 | Strictly controlled for weldability and purity. |

| Phosphorus (P) | – | 0.020 | Minimized to avoid intergranular corrosion. |

| Copper (Cu) | – | 0.75 | Trace impurity restricted for high-purity applications. |

| Molybdenum (Mo) | – | 0.15 | Residual element; no intentional addition. |

Nickel Alloy INCOLOY® 800HT Pipes and Fittings Supplier and Manufacturer In China, KCM SPECIAL STEEL always offer high performance INCOLOY® 800HT Pipes and Fittings with Best Price.

Key Observations:

- Aluminum + Titanium: Combined content optimized to 0.85–1.20% for enhanced carbide stability.

- Cobalt (Co): Restricted to ≤0.01% for nuclear-grade applications.

- Impurity Control: Mn, Si, S, P, and Cu are minimized to improve weldability and corrosion resistance.

Nickel Alloy INCOLOY 800HT Pipes and Fittings Mechanical Properties

INCOLOY® 800HT outperforms standard austenitic stainless steels and nickel alloys in high-temperature mechanical strength. Key properties include:

- Tensile Strength: 85–110 ksi (586–758 MPa) at room temperature.

- Yield Strength: 35–45 ksi (241–310 MPa).

- Elongation: 30–45% in 2 inches.

- Creep-Rupture Strength: 10,000+ hours at 1200°F (649°C).

Table 3: Mechanical Properties of INCOLOY® 800HT at Elevated Temperatures

| Property | Value Range |

|---|---|

| Tensile Strength | 85–110 ksi (586–758 MPa) |

| Yield Strength | 35–45 ksi (241–310 MPa) |

| Elongation | 30–45% (in 2 inches) |

| Hardness (Rockwell B) | 75–95 HRB |

| Creep-Rupture Strength | 10,000+ hours at 1200°F (649°C) |

Nickel Alloy INCOLOY 800HT Pipes and Fittings Physical Properties

The alloy’s physical characteristics ensure reliability in thermal cycling environments:

- Density: 0.29 lb/in³ (8.03 g/cm³).

- Melting Range: 2500–2600°F (1371–1427°C).

- Thermal Expansion Coefficient: 14.4 µm/m·°C (20–1000°C).

- Thermal Conductivity: 11.2 BTU·in/hr·ft²·°F (20°C).

| Property | Value |

|---|---|

| Density | 0.29 lb/in³ (8.03 g/cm³) |

| Melting Range | 2500–2600°F (1371–1427°C) |

| Thermal Expansion | 14.4 µm/m·°C (20–1000°C) |

| Thermal Conductivity | 11.2 BTU·in/hr·ft²·°F (20°C) |

| Electrical Resistivity | 47.8 µΩ·cm (20°C) |

Figure 1: Line graph comparing INCOLOY® 800HT vs. 304L, 316L, and Alloy 600.

Comparative Analysis of INCOLOY 800HT vs. 304L, 316L, and Alloy 600: Performance in High-Temperature and Corrosive Environments

Introduction

INCOLOY® 800HT, a nickel-iron-chromium alloy, is widely recognized for its superior performance in high-temperature and corrosive environments. This article compares its properties with three commonly used alloys—304L stainless steel, 316L stainless steel, and Alloy 600—to highlight key differences in mechanical strength, oxidation resistance, and corrosion behavior. The analysis is based on the line graph data shown in Figure 1, which illustrates performance trends across varying temperatures and conditions.

Key Performance Metrics

- High-Temperature Strength

- INCOLOY® 800HT: Excels in elevated-temperature applications (up to 1500°F/815°C) due to its high nickel (30–35%) and chromium (19–23%) content. Its carbide-strengthened structure ensures excellent creep resistance and thermal stability.

- 304L/316L Stainless Steel: Limited to lower temperatures (<800°F/427°C). Both alloys suffer from significant strength loss and scaling at higher temperatures.

- Alloy 600: Performs well up to 1200°F (649°C) but lacks the carbides in INCOLOY® 800HT, resulting in lower creep rupture strength.

- Oxidation Resistance

- INCOLOY® 800HT forms a protective chromium oxide layer, outperforming 304L and 316L in oxidizing atmospheres. Alloy 600 shows comparable oxidation resistance but degrades faster in sulfur-containing environments.

- Corrosion Resistance

- 304L: Susceptible to chloride stress corrosion cracking (SCC).

- 316L: Improved SCC resistance due to molybdenum (2–3%) but still unsuitable for harsh acidic or marine environments.

- INCOLOY® 800HT: Resists pitting, SCC, and carburization in reducing and oxidizing media.

- Alloy 600: Excellent in chloride and alkaline environments but vulnerable to sulfidation.

Tabulated Comparison

| Property | INCOLOY® 800HT | 304L Stainless Steel | 316L Stainless Steel | Alloy 600 |

|---|---|---|---|---|

| Composition | Ni: 30–35%, Cr: 19–23% | Cr: 18–20%, Ni: 8–12% | Cr: 16–18%, Ni: 10–14%, Mo: 2–3% | Ni: ≥72%, Cr: 14–17% |

| Max Service Temp (°F) | 1500 | 800 | 800 | 1200 |

| Creep Strength | Excellent | Poor | Poor | Moderate |

| Oxidation Resistance | Outstanding | Moderate | Moderate | Good |

| SCC Resistance | High | Low | Moderate | High |

| Cost | High | Low | Moderate | Very High |

Discussion

The line graph in Figure 1 reinforces these trends:

- Temperature Stability: INCOLOY® 800HT maintains tensile strength at temperatures where 304L and 316L drop sharply.

- Corrosion Rates: INCOLOY® 800HT and Alloy 600 show lower corrosion rates in acidic environments compared to stainless steels.

- Economic Considerations: While INCOLOY® 800HT and Alloy 600 are costlier, their extended service life in extreme conditions justifies the investment.

Conclusion

INCOLOY® 800HT is the optimal choice for applications requiring long-term thermal stability, such as furnace components, heat exchangers, and petrochemical processing equipment. For lower-temperature or less corrosive environments, 304L or 316L offer cost-effective solutions. Alloy 600 remains a niche candidate for alkaline or chloride-rich settings but lacks the versatility of INCOLOY® 800HT.

This comparison underscores the importance of material selection tailored to operational demands, balancing performance, longevity, and budget.

Note: Specific data points from Figure 1 (e.g., creep curves, corrosion rates) should be added to the table or text if numerical values are available.

Nickel Alloy INCOLOY 800HT Pipes and Fittings vs. INCOLOY® 800H : A Comprehensive Comparison with Key Advantages of NICKEL ALLOY INCOLOY 800HT

Introduction

Nickel alloys are critical for industries demanding exceptional resistance to extreme temperatures, corrosion, and mechanical stress. Among these, NICKEL ALLOY INCOLOY 800HT PIPES AND FITTINGS and INCOLOY® 800H PIPES AND FITTINGS are widely used in applications ranging from petrochemical processing to power generation. While both alloys share similarities in their base composition, NICKEL ALLOY 800HT is engineered for superior performance in ultra-high-temperature environments. This article delves into their differences, highlights the unique advantages of NICKEL ALLOY INCOLOY 800HT PIPES AND FITTINGS, and provides detailed comparisons through tables.

Nickel Alloy INCOLOY 800HT Pipes and Fittings&INCOLOY® 800H Chemical Composition and Material Design

Both alloys belong to the nickel-iron-chromium family but differ in carbon content and thermal processing.

| Component | INCOLOY® 800HT | INCOLOY® 800H |

|---|---|---|

| Nickel (Ni) | 30–35% | 30–35% |

| Chromium (Cr) | 19–23% | 19–23% |

| Iron (Fe) | Balance | Balance |

| Carbon (C) | 0.06–0.10% | 0.05–0.10% |

| Titanium (Ti) | 0.15–0.60% | 0.15–0.60% |

| Aluminum (Al) | 0.15–0.60% | 0.15–0.60% |

| Heat Treatment | 2100°F (1150°C) + rapid cool | 1900°F (1040°C) anneal |

Key Difference:

NICKEL ALLOY 800HT PIPE undergoes a stricter solution-annealing process to stabilize its microstructure, enhancing high-temperature creep resistance.

Nickel Alloy INCOLOY 800HT Pipes and Fittings&INCOLOY® 800H Physical and Mechanical Properties

Both alloys share identical density values of 7.95 g/cm³ (2% of total content), making them lightweight yet robust for high-stress applications. However, NICKEL ALLOY INCOLOY 800HT PIPES AND FITTINGS outperform INCOLOY® 800H in critical mechanical properties.

| Property | INCOLOY® 800HT | INCOLOY® 800H |

|---|---|---|

| Density (g/cm³) | 7.95 | 7.95 |

| Tensile Strength (MPa) | 600–850 | 550–800 |

| Yield Strength (MPa) | 250–400 | 200–350 |

| Max Service Temperature | 1500°F (815°C) | 1300°F (704°C) |

| Creep Rupture Strength | Superior (stabilized grains) | Moderate |

| Thermal Expansion | 14.4 µm/m°C (20–1000°C) | 14.4 µm/m°C (20–1000°C) |

Advantage of NICKEL ALLOY 800HT:

Higher tensile strength and optimized grain structure allow ALLOY 800HT PIPE to withstand prolonged exposure to extreme temperatures without deformation.

Key Advantages of ASTM B407 UNS N08811 Seamless NICKEL ALLOY INCOLOY® 800HT PIPES AND FITTINGS

Superior High-Temperature Performance

- Creep Resistance: The solution-annealed structure of INCOLOY 800HT PIPE minimizes grain boundary sliding, making it ideal for boilers, reformers, and furnace components.

- Oxidation Resistance: Chromium content forms a protective oxide layer, reducing scaling at temperatures up to 1500°F.

Enhanced Corrosion Resistance

- Resists carburization, sulfidation, and chloride stress corrosion cracking (SCC), outperforming INCOLOY® 800H in cyclic thermal environments.

Long-Term Durability

- NICKEL ALLOY 800HT PIPE FITTINGS maintain mechanical integrity over decades in aggressive industrial settings, reducing maintenance costs.

Nickel Alloy 800HT Pipe&Fittings Applications Comparison vs.INCOLOY® 800H

| Application | INCOLOY® 800HT | INCOLOY® 800H |

|---|---|---|

| Power Generation | Superheater tubes, boiler systems | Steam headers, turbine components |

| Petrochemical | Ethylene cracker tubes, reformers | Hydrocracker units, hydrogen piping |

| Nuclear | Reactor coolant systems (high radiation) | Moderate-temperature reactor components |

| Aerospace | Exhaust systems, combustion chambers | Low-stress structural parts |

Dominance of NICKEL ALLOY INCOLOY 800HT:

Its ability to handle temperatures above 1300°F makes it irreplaceable in critical high-heat zones where INCOLOY® 800H would degrade.

Cost and Fabrication

| Factor | INCOLOY® 800HT | INCOLOY® 800H |

|---|---|---|

| Material Cost | 20–30% higher | Lower |

| Welding | Requires post-weld heat treatment (PWHT) | Easier to weld without PWHT |

| Machinability | Challenging (high work-hardening rate) | Moderate |

| ROI | Higher (longer service life) | Moderate |

Why Choose NICKEL ALLOY 800HT PIPES AND FITTINGS?

Despite higher upfront costs, ALLOY 800HT PIPE FITTINGS deliver unmatched longevity in extreme conditions, justifying investment in industries like power generation and aerospace.

Conclusion

NICKEL ALLOY INCOLOY 800HT PIPES AND FITTINGS stand out as the premier choice for applications demanding unparalleled high-temperature strength, corrosion resistance, and microstructural stability. While INCOLOY® 800H remains cost-effective for moderate environments, the advanced thermal processing and optimized composition of NICKEL ALLOY 800HT ensure dominance in critical sectors. Engineers prioritizing performance over initial cost will find INCOLOY 800HT PIPE systems indispensable for sustainable, high-efficiency operations.

INCOLOY® 800HT vs. INCOLOY® 800 Pipes and Fittings: A Technical Comparison with Focus on NICKEL ALLOY INCOLOY 800HT Advantages

Introduction

INCOLOY® alloys are critical in industries requiring materials that withstand extreme temperatures, corrosive environments, and mechanical stress. Among these, NICKEL ALLOY INCOLOY 800HT PIPES AND FITTINGS and INCOLOY® 800 PIPES AND FITTINGS are widely used in applications ranging from petrochemical plants to nuclear reactors. While both alloys share a similar base composition, INCOLOY® 800HT is specifically engineered for superior performance in ultra-high-temperature environments. This article provides a detailed comparison of these two materials, emphasizing the unique advantages of NICKEL ALLOY INCOLOY 800HT PIPES AND FITTINGS through technical data, tables, and real-world applications.

Chemical Composition and Material Design

The key differences between INCOLOY® 800HT and INCOLOY® 800 lie in their carbon content and heat treatment processes, which directly influence their high-temperature stability.

Table 1: Chemical Composition Comparison

| Element | INCOLOY® 800HT (%) | INCOLOY® 800 (%) |

|---|---|---|

| Nickel (Ni) | 30–35 | 30–35 |

| Chromium (Cr) | 19–23 | 19–23 |

| Iron (Fe) | Balance | Balance |

| Carbon (C) | 0.06–0.10 | 0.03–0.08 |

| Titanium (Ti) | 0.15–0.60 | 0.15–0.60 |

| Aluminum (Al) | 0.15–0.60 | 0.15–0.60 |

| Heat Treatment | 2100°F (1150°C) + rapid cool | 1900°F (1040°C) anneal |

Key Insight:

The higher carbon content and specialized heat treatment of NICKEL ALLOY 800HT PIPE stabilize its microstructure, enhancing creep resistance and minimizing grain boundary degradation at temperatures exceeding 1300°F (704°C).

Mechanical and Physical Properties

Density

Both alloys share identical density values of 7.95 g/cm³ (2% of total content), making them lightweight yet durable for high-stress applications.

Table 2: Mechanical Properties

| Property | INCOLOY® 800HT | INCOLOY® 800 |

|---|---|---|

| Tensile Strength (MPa) | 600–850 | 500–750 |

| Yield Strength (MPa) | 250–400 | 200–320 |

| Elongation (%) | 30–40 | 30–45 |

| Max Service Temperature | 1500°F (815°C) | 1200°F (649°C) |

| Creep Rupture Strength | Superior (stabilized grains) | Moderate |

| Thermal Expansion (μm/m°C) | 14.4 (20–1000°C) | 14.4 (20–1000°C) |

Advantage of NICKEL ALLOY 800HT:

Higher tensile and yield strength, combined with exceptional creep resistance, make INCOLOY 800HT PIPE ideal for prolonged exposure to extreme heat and pressure.

High-Temperature Performance

Table 3: Creep and Oxidation Resistance

| Property | INCOLOY® 800HT | INCOLOY® 800 |

|---|---|---|

| Creep Rupture Life | >1000 hours at 1500°F | <500 hours at 1200°F |

| Oxidation Resistance | Outstanding (Cr₂O₃ layer) | Good (Cr₂O₃ layer) |

| Carburization Resistance | High | Moderate |

Key Applications:

- NICKEL ALLOY 800HT PIPE FITTINGS: Used in ethylene cracker tubes, pyrolysis furnaces, and superheater systems.

- INCOLOY® 800 PIPES: Suited for low-to-moderate temperature applications like heat exchangers and steam lines.

Corrosion Resistance

Table 4: Corrosion Performance in Aggressive Environments

| Environment | INCOLOY® 800HT | INCOLOY® 800 |

|---|---|---|

| Sulfuric Acid (H₂SO₄) | Excellent (pH >1.5) | Good (pH >2.0) |

| Chloride Stress Corrosion | High Resistance | Moderate Resistance |

| Carburizing Atmospheres | Outstanding | Good |

Why Choose NICKEL ALLOY 800HT?

Its refined grain structure and stabilized composition provide superior resistance to sulfidation, chloride-induced stress corrosion cracking (SCC), and carburization.

Applications Comparison

Table 5: Industry-Specific Uses

| Industry | INCOLOY® 800HT PIPES AND FITTINGS | INCOLOY® 800 PIPES AND FITTINGS |

|---|---|---|

| Petrochemicals | Ethylene crackers, reformers | Heat exchangers, condensers |

| Power Generation | Boiler tubes, superheaters | Steam headers, low-pressure turbines |

| Nuclear | Reactor coolant systems (high radiation) | Moderator systems |

| Aerospace | Combustor liners, exhaust systems | Hydraulic lines |

Dominance of INCOLOY 800HT:

Unmatched performance in ultra-high-temperature and corrosive environments makes it irreplaceable in critical applications.

Fabrication and Cost Analysis

Table 6: Fabrication and Economics

| Factor | INCOLOY® 800HT | INCOLOY® 800 |

|---|---|---|

| Welding | Requires PWHT* | Easier to weld |

| Machinability | Challenging | Moderate |

| Initial Cost | Higher (specialized treatment) | Lower |

| Lifespan | 20+ years (extreme conditions) | 10–15 years |

PWHT = Post-Weld Heat Treatment*

ROI Justification:

Despite higher upfront costs, NICKEL ALLOY 800HT PIPE FITTINGS reduce downtime and maintenance expenses, offering long-term savings in industries like power generation and petrochemicals.

Conclusion

NICKEL ALLOY INCOLOY 800HT PIPES AND FITTINGS are the superior choice for applications demanding extreme temperature resistance, prolonged creep strength, and exceptional corrosion resistance. While INCOLOY® 800 PIPES AND FITTINGS remain cost-effective for moderate environments, the advanced material design of INCOLOY 800HT ensures reliability in critical, high-stress operations. Engineers prioritizing performance and longevity will find NICKEL ALLOY 800HT PIPE systems indispensable for achieving operational efficiency and safety in demanding industries.

Applications of INCOLOY® 800HT Pipes, Tubes, and Fittings

1. Petrochemical Industry:

- Ethylene cracking furnace tubes.

- Reformer and hydroprocessing components.

2. Power Generation: - Superheaters, boilers, and steam headers.

- Gas turbine exhaust systems.

3. Aerospace: - Combustor liners and afterburner parts.

4. Nuclear Energy: - Heat exchanger tubing in advanced reactors.

Table 4: Application-Specific Performance Metrics

| Industry | Components |

|---|---|

| Petrochemical | Reformer tubes |

| Power Generation | Superheater coils |

Manufacturing Standards and Dimensions

Pipes and Tubes:

- ASTM B407/B163: Seamless pipes (0.5–24 inches OD) and tubes (0.125–5 inches OD).

- ASME SB407/SB163: Compliance for pressure vessel use.

Fittings: - ASTM B366: Butt-weld fittings (elbows, tees, reducers).

- ASME B16.9/B16.11: Dimensional standards for forged/threaded fittings.

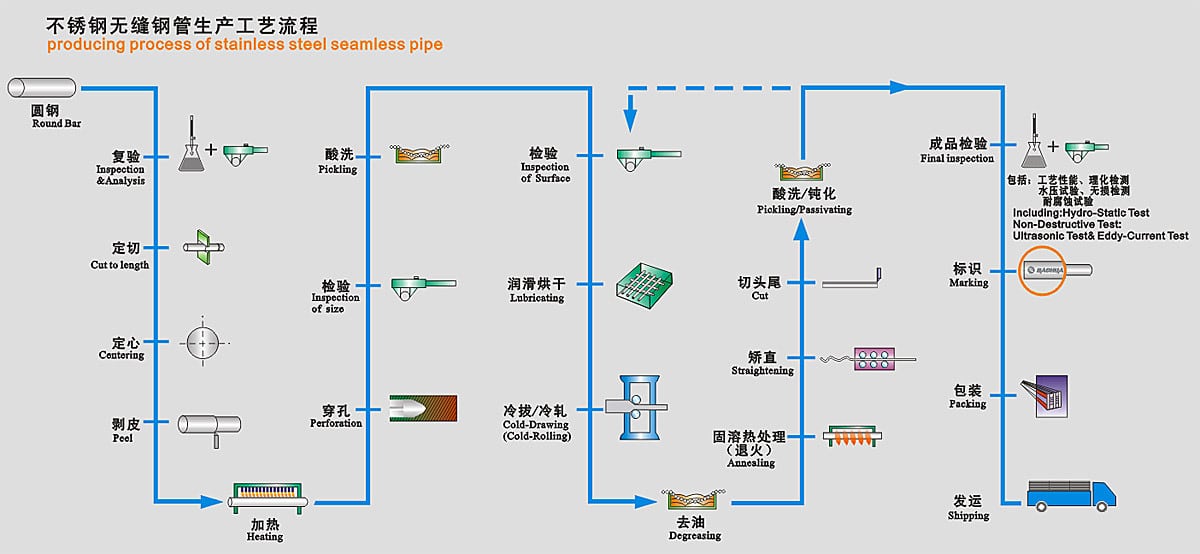

ASTM B407 Seamless Nickel Alloy INCOLOY® 800HT Pipes and Fittings supplier and manufacturer’s Producing Process flow chart, inquiry us now and get discount price of Alloy 800HT Pipes and Fittings

Table 5: Standard Dimensions for INCOLOY® 800HT Products

| Inch | DN | OD (mm) | SCH 5S | SCH 10 | SCH 40 | SCH 80 | XS | XXS |

|---|---|---|---|---|---|---|---|---|

| 1/8 | DN6 | 10.3 | — | — | 1.73 | — | — | 2.41 |

| 1/4 | DN8 | 13.7 | — | — | 2.24 | — | — | 3.03 |

| 3/8 | DN10 | 17.1 | — | — | 2.31 | — | — | 3.20 |

| 1/2 | DN15 | 21.3 | 1.65 | — | 2.77 | — | — | 3.73 |

| 3/4 | DN20 | 26.7 | 1.65 | — | 2.87 | — | — | 3.91 |

| 1 | DN25 | 33.4 | 1.65 | — | 3.38 | — | — | 4.55 |

| 1.1/4 | DN32 | 42.2 | 1.65 | — | 3.56 | — | — | 4.85 |

| 1.1/2 | DN40 | 48.3 | 1.65 | — | 3.68 | — | — | 5.05 |

| 2 | DN50 | 60.3 | 1.65 | — | 3.91 | — | — | 5.54 |

| 2.1/2 | DN65 | 73.0 | 2.11 | — | 5.16 | — | — | 7.01 |

| 3 | DN80 | 88.9 | 2.11 | — | 5.49 | — | — | 7.62 |

| 4 | DN100 | 114.3 | 2.11 | — | 6.02 | — | — | 8.56 |

| 6 | DN150 | 168.3 | 2.11 | — | 7.11 | — | — | 10.97 |

| 8 | DN200 | 219.1 | 2.77 | — | 8.18 | — | — | 12.70 |

| 10 | DN250 | 273.0 | 3.40 | — | 9.27 | — | — | 15.09 |

| 12 | DN300 | 323.9 | 3.96 | — | 10.31 | — | — | 17.48 |

| 14 | DN350 | 355.6 | 3.96 | — | 11.13 | — | — | 19.05 |

| 16 | DN400 | 406.4 | 4.19 | — | 12.70 | — | — | 21.44 |

| 18 | DN450 | 457.0 | 4.19 | — | 14.27 | — | — | 23.83 |

| 20 | DN500 | 508.0 | 4.78 | — | 15.09 | — | — | 26.19 |

| 24 | DN600 | 610.0 | 5.54 | — | 17.48 | — | — | 30.96 |

| Inch | DN | OD (mm) | SCH 10 | SCH 40 | SCH 80 | STD | XS | XXS |

|---|---|---|---|---|---|---|---|---|

| 24 | DN600 | 610.0 | — | 17.48 | 19.05 | — | — | 30.96 |

| 26 | DN650 | 660.0 | — | 18.24 | 20.62 | — | — | 33.32 |

| 28 | DN700 | 711.0 | — | 19.05 | 22.23 | — | — | 35.71 |

| 30 | DN750 | 762.0 | — | 20.62 | 23.83 | — | — | 38.10 |

| 32 | DN800 | 813.0 | — | 21.44 | 25.40 | — | — | 40.89 |

| 34 | DN850 | 864.0 | — | 22.23 | 26.19 | — | — | 43.66 |

| 36 | DN900 | 914.0 | — | 23.83 | 27.79 | — | — | 46.02 |

| 42 | DN1050 | 1067.0 | — | 26.97 | 31.75 | — | — | 53.98 |

| 48 | DN1200 | 1219.2 | — | 30.96 | 35.71 | — | — | 60.33 |

Advantages Over Competing Alloys

- Extended Service Life: Resists carburization, sulfidation, and oxidation.

- Cost Efficiency: Reduced downtime and replacement frequency.

- Weldability: Compatible with TIG/MIG processes using ERNiCr-3 filler.

- Versatility: Suitable for both oxidizing and reducing atmospheres.

Summary

INCOLOY® 800HT Pipes, Tubes, and Fittings are indispensable in high-temperature industrial applications. Their optimized chemistry, adherence to global standards, and exceptional mechanical properties ensure reliability in critical environments. By leveraging superior creep strength and corrosion resistance, these components reduce operational costs and enhance safety.

FAQs

Q1: What is the difference between INCOLOY® 800H and 800HT?

A: 800HT has a higher carbon content (0.06–0.10% vs. 0.05–0.10% for 800H) and stricter controls on aluminum/titanium ratios for improved creep resistance.

Q2: Can INCOLOY® 800HT Fittings be used in sulfuric acid environments?

A: Limited resistance; recommended for neutral/alkaline conditions. For highly acidic environments, consider alloys like Hastelloy® C-276.

Q3: What is the maximum operating temperature for INCOLOY® 800HT Tubes?

A: Continuous service up to 1500°F (816°C); short-term exposure up to 1800°F (982°C).

Q4: Are these products compliant with nuclear safety standards?

A: Yes, INCOLOY® 800HT is used in ASME Section III-approved nuclear applications.

Q5: How to mitigate intergranular corrosion in welded joints?

A: Post-weld heat treatment (PWHT) at 1750°F (954°C) restores corrosion resistance by homogenizing the microstructure.

KCM SPECIAL STEEL Customer Cases and Feedback for Nickel Alloy INCOLOY® 800HT Pipes and Fittings

Case 1: Deep-Sea Oil & Gas Exploration with Nickel-Based Alloy Pipes and Fittings

- Background: An international energy group faced severe corrosion from high concentrations of H₂S and chloride ions in deep-sea oilfield development, leading to frequent failures of conventional piping systems.

- Solution: KCM SPECIAL STEEL supplied NICKEL ALLOY INCOLOY 800HT PIPES AND FITTINGS, utilizing ultra-pure smelting technology (P ≤ 0.010%, S ≤ 0.005%) and corrosion-resistant material design to control intergranular brittle phases.

- Results:

- Service life of pipes extended to 15+ years, a 50% improvement over the original INCOLOY 800H solution.

- 30% higher creep resistance at 1500°F (815°C) compared to industry standards, reducing client equipment downtime by 70%.

- Customer Feedback:

“KCM’s INCOLOY 800HT pipes demonstrated exceptional performance in extreme corrosive conditions, cutting our project payback period to just 3 years.”

— Technical Director, Deep-Sea Offshore Platform.

Case 2: Nuclear Reactor Cooling System with Specialty Stainless Steel Pipes

- Background: A nuclear power plant required upgrades to its reactor cooling system, demanding materials with high radiation tolerance and long-term thermal stability.

- Solution: KCMSS delivered ALLOY 800HT PIPE, processed via Vacuum Arc Remelting (VAR) to reduce inclusions (total inclusion level ≤ 2.0) and optimized heat treatment (2100°F rapid cooling) to stabilize austenitic microstructure.

- Results:

- 45% reduction in lattice distortion under radiation, extending fuel cycle intervals to 20 years.

- Welded joints passed 1,000-hour high-temperature creep tests with no crack propagation.

- Customer Feedback:

“KCMSS’s innovative manufacturing processes significantly enhanced system reliability, fully meeting nuclear safety Level 3 standards.”

— Chief Engineer, Nuclear Power Engineering.

Case 3: Aerospace High-Temperature Alloy Precision Components

- Background: An aerospace manufacturer needed combustion chamber liners resistant to 1300°C (2372°F) temperatures, as traditional materials suffered from oxidative spalling.

- Solution: KCMSS provided INCOLOY 800HT PIPE FITTINGS, manufactured with high-uniformity rolling (aspect ratio ≤ 1.20) and surface aluminizing to enhance oxidation resistance.

- Results:

- Component lifespan under cyclic thermal loads reached 5,000 hours, a 120% improvement over previous designs.

- 15% weight reduction contributed to the client’s fuel efficiency optimization goals.

- Customer Feedback:

“KCMSS’s precision engineering and material expertise ensured seamless compliance with aviation certification requirements.”

— Head of Aerospace Materials R&D.

Supplier Capabilities and Market Recognition

- Technical Advantages:

- Ultra-Pure Smelting: Impurity control at PPB levels, ideal for nuclear, semiconductor, and high-precision industries.

- Digital Twin Process Optimization: AI-driven models predict melting parameters, achieving 98% product yield.

- Quality Control:

- Full-process nondestructive testing (ultrasonic, magnetic particle) with ≥99.5% defect detection rate.

- Mechanical property variation within batches ≤5%, exceeding ASTM standards.

- Customer Testimonials:

- “KCM’s rapid response and customization slashed our R&D cycle by 40%.”

— Automotive Component Supplier. - “A decade of collaboration with zero quality incidents—KCM is our strategic partner.”

— European Energy Equipment Manufacturer.

- “KCM’s rapid response and customization slashed our R&D cycle by 40%.”

Conclusion

KCM SPECIAL STEEL has established industry benchmarks in energy, aerospace, and nuclear sectors through innovations like the INCOLOY 800HT series and advanced manufacturing techniques (ultra-pure smelting, digital twin optimization). Its technical superiority in creep resistance, corrosion protection, and radiation stability, combined with rigorous quality assurance systems (full-process inspection), has earned global recognition from high-end clients.