Description

DUPLEX 2304 STAINLESS STEEL PIPE BRIEF INTRODUCTION

DUPLEX 2304 STAINLESS STEEL PIPE / Duplex 2304 pipe is a low-alloy duplex stainless steel developed by Sweden.It has a solution temperature of about 1000 ℃, the organization has 40% -50% ferrite and 50% -60% austenite, with the common characteristics of duplex stainless steel, Is as a high strength and inexpensive features, can replace the 304L and 316L commonly used austenitic stainless steel and the development of steel.

It has been recognized by the American Society of Mechanical Engineers (ASME) for use in boilers and pressure vessels, chemical plants and refineries, and many countries have incorporated standards.

US standard for the UNS S32304, Sweden’s commercial grade SAF 2304 .

UNS S32304 / SAF 2304 DUPLEX STAINLESS STEEL PIPE RELATED PRODUCTS OFFERING BY KCM SPECIAL STEEL

1. DUPLEX 2304 STAINLESS STEEL PIPE SEAMLESS

2. DUPLEX 2304 STAINLESS STEEL PIPE WELDED

3. DUPLEX 2304 STAINLESS STEEL TUBE SEAMLESS

4. DUPLEX 2304 STAINLESS STEEL TUBE WELDED

5. DUPLEX 2304 STAINLESS STEEL PIPE FITTINGS

6. DUPLEX 2304 STAINLESS STEEL PIPE FLANGES

7. DUPLEX 2304 STAINLESS STEEL VALVES

DUPLEX 2304 STAINLESS STEEL PIPE CHEMICAL COMPOSITION:

UNS S32304=C ≤ 0.030 、 Si ≤ 1.0 、 Mn ≤ 2.5 、 S ≤ 0.030 、 P ≤ 0.040 、 Cr: 21.5 – 24.5 、 Ni: 3.0 – 5.5 、 Mo: 0.05 – 0.6 、N: 0.05 – 0.20 、 Cu:0.05 – 0.6

SAF2304=C ≤ 0.030 、 Si ≤ 0.5 、 Mn ≤ 1.2 、 S ≤ 0.04 、 P ≤ 0.04 、 Cr: 23 、 Ni: 4.5 、 N: 0.1

DUPLEX 2304 PIPE UNS S32304 / SAF2304 MECHANICAL PROPERTY:

GRADE | STEEL TYPE | temperature ℃ | σb/MPa | σ0.2/MPa | δ5/% |

SAF 2304 | STEEL PIPE Φ≤25.4mm | Room temperature | ≥690 | ≥450 | ≥25 |

STEEL PLATE | room temperature | ≥600 | ≥400 | ≥25 | |

50℃ | 600 | 370 | —— | ||

100℃ | 570 | 330 | —— | ||

200℃ | 530 | 290 | —— | ||

300℃ | 500 | 260 | —— |

DUPLEX 2304 STAINLESS STEEL PIPE CORROSION RESISTANCE:

duplex 2304 duplex stainless steel pipe PRE value of 25, and 316L stainless steel value equivalent.The CPT value of duplex 2304 stainless steel pipewas higher than that of 304L, which was equivalent to that of 316L when the critical pitting temperature (CPT) and chloride ion content of several steels were tested in NaCl solution at 300mV.

The results of several steels in the neutral chloride solution of the autoclave found that the applied stress was equivalent to the yield strength of the steel at this temperature, and the test time was 1000 h, where the stress corrosion cracking did not occur under the curve.In addition SAF2304 duplex 2304 stainless steel pipe corrosion resistance between the good, can be CuSO4 + H2SO4 copper method test.

SAF2304 dual phase steel in nitric acid has a good corrosion resistance, can be comparable with 304L, in other acids, such as sulfuric acid, its corrosion resistance with 316L, and in organic acids, such as formic acid, and even better than 316L.

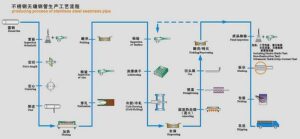

DUPLEX 2304 STAINLESS STEEL PIPE SEAMLESS PRODUCTION PROCESS:

ASTM A 790 / A 789 UNS S32304 / DUPLEX 2304 STAINLESS STEEL PIPE SEAMLESS PRODUCTION PROCESS

WELDED PIPE PRODUCTION PROCESS:

DUPLEX 2304 STAINLESS STEEL PIPE WELDED SUPPLIERS,MANUFACTURER,CONTACT US FOR LOW PRICE AND HIGH QUALITY DUPLEX 2304 STAINLESS STEEL PIPE

SAF 2304 STAINLESS STEEL PIPE WELDING PROPERTY:

duplex 2304 stainless steel pipe has good welding performance, no heat treatment before welding. Suitable for SMAW, GTAW, GMAW and SAW method for welding. When welding with GTAW method, fill wire is required and use pure argon or Ar + 2% N2 shielding gas.

Uns s32304 STAINLESS STEEL PIPE EXCUTIVE STANDARD

ASTM A789-08a General Purpose Seamless and Welded Ferritic / Austenitic Stainless Steel Tubes

ASTM A790 / A790M – 11 Seamless and welded ferritic / austenitic stainless steel nominal tube

DUPLEX 2304 STAINLESS STEEL PIPE APPLICATIONS:

SAF 2304 stainless steel pipe has good mechanical and physical properties, resistance to stress corrosion and other forms of corrosion and good weldability, it may instead replace 304,304 L, 316,316 L and other austenitic stainless steel. Can be used in the manufacture of amine recovery equipment, hydrocarbon fermentation equipment, in addition, can also be used as a manufacturing industry heat exchangers, pulp and paper industry, cooking pot preheater and hot and humid, coastal areas such as the train seat

DUPLEX 2304 STAINLESS STEEL PIPE AVAILABLE SIZES TO ARRANGE PRODUCTION:

| Dimensions for ASME/ANSI Standards | Unit:mm | ||||||||||||

| B16.9 B16.28 B36.10 | |||||||||||||

| Nominal pipe Size(NPS) | Outside Diameter | Nominal Wall Thickness | |||||||||||

| Sch5s | SCH10S | Sch20 | Sch30 | Sch40 | STD | Sch80 | XS | Sch160 | XXS | ||||

| 8 | 1/4 | 13.7 | 0.54 | – | 1.65 | – | 1.85 | 2.24 | 2.24 | 3.02 | 3.02 | – | – |

| 10 | 3/8 | 17.1 | 0.675 | – | 1.65 | – | 1.85 | 2.31 | 2.31 | 3.20 | 3.20 | – | – |

| 15 | 1/2 | 21.3 | 0.84 | 1.65 | 2.11 | – | 2.41 | 2.77 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 |

| 20 | 3/4 | 26.7 | 1.05 | 1.65 | 2.11 | – | 2.41 | 2.87 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 |

| 25 | 1 | 33.4 | 1.32 | 1.65 | 2.77 | – | 2.90 | 3.38 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 |

| 32 | 1.1/4 | 42.2 | 1.66 | 1.65 | 2.77 | – | 2.97 | 3.56 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 |

| 40 | 1.1/2 | 48.3 | 1.90 | 1.65 | 2.77 | – | 3.18 | 3.68 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 |

| 50 | 2 | 60.3 | 2.38 | 1.65 | 2.77 | – | 3.18 | 3.91 | 3.91 | 5.54 | 5.54 | 8.74 | 11.07 |

| 65 | 2.1/2 | 73.0 | 2.88 | 2.11 | 3.05 | – | 4.78 | 5.16 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 |

| 80 | 3 | 88.9 | 3.50 | 2.11 | 3.05 | – | 4.78 | 5.49 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 |

| 90 | 3.1/2 | 101.6 | 4.00 | 2.11 | 3.05 | – | 4.78 | 5.74 | 5.74 | 8.08 | 8.08 | – | – |

| 100 | 4 | 114.3 | 4.50 | 2.11 | 3.05 | – | 4.78 | 6.02 | 6.02 | 8.56 | 8.56 | 13.49 | 17.12 |

| 125 | 5 | 141.3 | 5.56 | 2.77 | 3.40 | – | – | 6.55 | 6.55 | 9.53 | 9.53 | 15.88 | 19.05 |

| 150 | 6 | 168.3 | 6.62 | 2.77 | 3.40 | – | – | 7.11 | 7.11 | 10.97 | 10.97 | 18.26 | 21.96 |

| 200 | 8 | 219.1 | 8.62 | 2.77 | 3.76 | 6.35 | 7.04 | 8.18 | 8.18 | 12.70 | 12.70 | 23.01 | 22.23 |

| 250 | 10 | 273.0 | 10.75 | 3.40 | 4.19 | 6.35 | 7.80 | 9.27 | 9.27 | 15.09 | 12.70 | 28.58 | 25.40 |

| 300 | 12 | 323.8 | 12.75 | 3.96 | 4.57 | 6.35 | 8.38 | 10.13 | 9.53 | 17.48 | 12.70 | 33.32 | 25.40 |

| 350 | 14 | 355.6 | 14 | 3.96 | 4.78 | 7.92 | 9.53 | 11.13 | 9.53 | 19.05 | 12.70 | 35.71 | – |

| 400 | 16 | 406.4 | 16 | 4.19 | 4.78 | 7.92 | 9.53 | 12.70 | 9.53 | 21.44 | 12.70 | 40.49 | – |

| 450 | 18 | 457 | 18 | 4.19 | 4.78 | 7.92 | 11.13 | 14.27 | 9.53 | 23.83 | 12.70 | 45.24 | – |

| 500 | 10 | 508 | 20 | 4.78 | 5.54 | 9.53 | 12.70 | 15.09 | 9.53 | 26.19 | 12.70 | 50.01 | – |

| 550 | 22 | 559 | 22 | 4.78 | 5.54 | 9.53 | 12.70 | – | 9.53 | 28.58 | 12.70 | 53.98 | – |

| 600 | 24 | 610 | 24 | 5.54 | 6.35 | 9.53 | 14.27 | 17.48 | 9.53 | 30.96 | 12.70 | 59.54 | – |

| 650 | *26 | 660 | 26 | – | – | – | – | – | 9.53 | – | 12.70 | – | – |

| 700 | *28 | 711 | 28 | – | – | – | – | – | 9.53 | – | 12.70 | – | – |

| 750 | *30 | 762 | 30 | – | – | – | – | – | 9.53 | – | 12.70 | – | – |

| 800 | *32 | 813 | 32 | – | – | – | – | – | 9.53 | – | 12.70 | – | – |

Weight & Thickness Chart Of Duplex 2304 Pipes

| NPS | Outside Diameter | Wall Thickness | Weight | Weight | |||

| in | mm | in | mm | Sched | kg/Mtr | Lb/ft | |

| 1/2″ | 0.840 | 21 | 0.109 | 2.769 | 40 STD | 1.268 | 0.851 |

| 0.147 | 3.734 | 80 STD | 1.621 | 1.088 | |||

| 3/4″ | 1.050 | 27 | 0.113 | 2.870 | 40 STD | 1.684 | 1.131 |

| 0.154 | 3.912 | 80 STD | 2.195 | 1.474 | |||

| 1″ | 1.315 | 33 | 0.133 | 3.378 | 40 STD | 2.501 | 1.679 |

| 0.179 | 4.547 | 80 STD | 3.325 | 2.172 | |||

| 1 1/4″ | 1.660 | 42 | 0.140 | 3.556 | 40 STD | 3.385 | 2.273 |

| 0.191 | 4.851 | 80 STD | 4.464 | 2.997 | |||

| 1 1/2″ | 1.900 | 48 | 0.145 | 3.683 | 40 STD | 4.048 | 2.718 |

| 0.200 | 5.080 | 80 STD | 5.409 | 3.361 | |||

| 2″ | 2.375 | 60 | 0.154 | 3.912 | 40 STD | 5.441 | 3.653 |

| 0.218 | 5.537 | 80 STD | 7.480 | 5.022 | |||

| 2 1/2″ | 2.875 | 73 | 0.203 | 5.516 | 40 STD | 8.629 | 5.793 |

| 0.276 | 7.010 | 80 STD | 11.411 | 7.661 | |||

| 3″ | 3.500 | 89 | 0.216 | 5.486 | 40 STD | 11.284 | 7.576 |

| 0.300 | 7.620 | 80 STD | 15.272 | 10.253 | |||

| 4″ | 4.500 | 114 | 0.237 | 6.020 | 16.073 | 10.790 | |

| 0.337 | 8.560 | 22.318 | 14.983 | ||||

| 6″ | 6.625 | 168 | 0.188 | 4.775 | 19.252 | 12.924 | |

| 0.203 | 5.516 | 20.739 | 13.923 | ||||

| 0.219 | 5.563 | 22.318 | 14.983 | ||||

| 0.250 | 6.350 | 25.354 | 17.021 | ||||

| 0.280 | 7.112 | 40 STD | 58.263 | 18.974 | |||

| 0.312 | 7.925 | 31.334 | 21.036 | ||||

| 0.375 | 9.525 | 37.285 | 25.031 | ||||

| 0.432 | 10.973 | 80 XHY | 42.561 | 28.573 | |||

| 0.500 | 12.700 | 48.719 | 32.708 | ||||

| 8″ | 8.625 | 219 | 0.188 | 4.775 | 25.233 | 16.940 | |

| 0.203 | 5.156 | 27.198 | 18.259 | ||||

| 0.219 | 5.563 | 29.286 | 19.661 | ||||

| 0.250 | 6.350 | 20 | 33.308 | 22.361 | |||

| 0.277 | 7.036 | 30 | 36.786 | 24.696 | |||

| 0.322 | 8.179 | 40 | 42.352 | 28.554 | |||

| 0.375 | 9.525 | 49.216 | 33.041 | ||||

| 0.406 | 10.312 | 60 | 53.085 | 35.638 | |||

| 0.500 | 12.700 | 80 XHY | 64.627 | 43.388 | |||

| 10″ | 10.750 | 273 | 0.188 | 4.775 | 31.588 | 21.207 | |

| 0.219 | 5.563 | 36.689 | 24.631 | ||||

| 0.250 | 6.350 | 20 | 41.759 | 28.035 | |||

| 0.307 | 7.798 | 30 | 51.002 | 34.240 | |||

| 0.344 | 8.738 | 56.946 | 38.231 | ||||

| 0.365 | 9.271 | 40 STD | 63.301 | 40.483 | |||

| 0.438 | 11.125 | 71.852 | 48.238 | ||||

| 0.500 | 12.700 | 60 XHY | 81.530 | 54.735 | |||

| 0.594 | 15.088 | 80 | 95.969 | 64.429 | |||

| 12″ | 12.750 | 324 | 0.188 | 4.775 | 37.570 | 25.222 | |

| 0.219 | 5.563 | 43.657 | 29.309 | ||||

| 0.250 | 6.350 | 49.713 | 33.375 | ||||

| 0.281 | 7.137 | 55.739 | 37.420 | ||||

| 0.312 | 7.925 | 61.735 | 41.445 | ||||

| 0.375 | 9.525 | 73.824 | 49.562 | ||||

| 0.406 | 10.312 | 79.727 | 53.525 | ||||

| 0.500 | 12.700 | 97.438 | 65.415 | ||||

| 0.562 | 14.275 | 108.966 | 73.154 | ||||

| 14″ | 14.000 | 356 | 0.188 | 4.775 | 41.308 | 27.732 | |

| 0.219 | 5.563 | 48.012 | 32.233 | ||||

| 0.250 | 6.350 | 20 | 54.685 | 36.713 | |||

| 0.281 | 7.137 | 61.327 | 41.172 | ||||

| 0.312 | 7.925 | 67.939 | 45.611 | ||||

| 0.375 | 9.525 | STD | 81.281 | 54.568 | |||

| 0.438 | 11.125 | 40 | 94.498 | 63.441 | |||

| 0.500 | 12.700 | XHY | 107.381 | 72.090 | |||

| 0.625 | 15.875 | 132.983 | 89.278 | ||||

| 16” | 16.000 | 406 | 0.188 | 4.775 | 47.290 | 21.748 | |

| 0.219 | 5.563 | 54.980 | 36.910 | ||||

| 0.250 | 6.350 | 10 | 62.639 | 42.053 | |||

| 0.281 | 7.137 | 70.268 | 47.174 | ||||

| 0.312 | 7.925 | 20 | 77.866 | 52.275 | |||

| 0.344 | 8.738 | 85.677 | 57.519 | ||||

| 0.375 | 9.525 | 30 STD | 93.213 | 62.578 | |||

| 0.438 | 11.125 | 108.433 | 72.797 | ||||

| 0.500 | 12.700 | 40 XHY | 123.289 | 82.770 | |||

| 18″ | 18.000 | 457 | 0.219 | 5.563 | 61.948 | 41.588 | |

| 0.250 | 6.350 | 70.593 | 47.393 | ||||

| 0.281 | 7.137 | 79.208 | 53.176 | ||||

| 0.312 | 7.925 | 20 | 87.792 | 58.939 | |||

| 0.375 | 9.525 | STD | 105.144 | 70.588 | |||

| 0.438 | 11.125 | 30 | 122.369 | 82.152 | |||

| 0.500 | 12.700 | XHY | 139.198 | 93.450 | |||

| 0.562 | 14.275 | 40 | 155.904 | 104.666 | |||

| 0.625 | 15.875 | 172.754 | 115.978 | ||||

| 20″ | 20.000 | 508 | 0.250 | 6.350 | 78.547 | 52.733 | |

| 0.282 | 7.163 | 88.458 | 59.386 | ||||

| 0.312 | 7.925 | 97.719 | 65.604 | ||||

| 0.375 | 9.525 | 20 STD | 117.075 | 78.598 | |||

| 0.438 | 11.125 | 136.305 | 91.508 | ||||

| 0.500 | 12.700 | 30 XHY | 155.106 | 104.130 | |||

| 0.594 | 15.088 | 40 | 183.378 | 123.110 | |||

| 0.625 | 15.875 | 192.640 | 129.328 | ||||

| 0.688 | 17.475 | 211.368 | 141.901 | ||||

| 24″ | 24.000 | 610 | 0.250 | 6.350 | 94.456 | 63.413 | |

| 0.281 | 7.137 | 106.029 | 71.183 | ||||

| 0.312 | 7.925 | 117.573 | 18.932 | ||||

| 0.375 | 9.525 | 20 STD | 140.938 | 64.618 | |||

| 0.438 | 11.125 | 164.176 | 110.219 | ||||

| 0.500 | 12.700 | XHY | 186.923 | 125.490 | |||

| 0.625 | 15.875 | 232.410 | 156.028 | ||||

| 0.688 | 17.475 | 40 | 255.148 | 171.293 | |||

| 0.750 | 19.050 | 277.401 | 186.233 | ||||

| 30″ | 30.000 | 762 | 0.250 | 6.350 | 118.318 | 79.433 | |

| 0.281 | 7.137 | 132.851 | 89.189 | ||||

| 0.312 | 7.925 | 10 | 147.353 | 98.925 | |||

| 0.375 | 9.525 | STD | 176.731 | 118.648 | |||

| 0.438 | 11.125 | 205.983 | 138.286 | ||||

| 0.500 | 12.700 | 20 XHY | 234.647 | 157.530 | |||

| 0.625 | 15.875 | 30 | 292.066 | 196.078 | |||

| 0.688 | 17.475 | 320.817 | 215.380 | ||||

| 0.750 | 19.050 | 348.988 | 234.293 | ||||

| 36″ | 36.000 | 914 | 0.250 | 6.350 | 142.180 | 95.453 | |

| 0.281 | 7.137 | 159.672 | 107.196 | ||||

| 0.312 | 7.925 | 10 | 177.133 | 118.918 | |||

| 0.375 | 9.525 | STD | 215.525 | 142.678 | |||

| 0.438 | 11.125 | 247.790 | 166.353 | ||||

| 0.500 | 12.700 | 20 XHY | 282.372 | 198.570 | |||

| 0.625 | 15.875 | 351.723 | 236.128 | ||||

| 0.688 | 17.475 | 386.487 | 259.467 | ||||

| 0.750 | 19.050 | 420.576 | 282.353 | ||||

| 42″ | 42.000 | 1067 | 0.312 | 7.925 | 206.914 | 138.911 | |

| 0.375 | 9.525 | STD | 248.319 | 166.708 | |||

| 0.500 | 12.700 | XHY | 33.097 | 221.610 | |||

| 0.750 | 19.050 | 492.163 | 330.413 | ||||

| 48″ | 48.000 | 1219 | 0.375 | 9.525 | STD | 284.112 | 190.738 |

| 0.438 | 11.125 | 331.404 | 222.487 | ||||

| 0.500 | 12.700 | XHY | 377.822 | 253.650 | |||

| 0.750 | 19.050 | 563.750 | 378.473 | ||||

| 0.875 | 22.225 | 655.969 | 440.383 | ||||

DUPLEX 2304 STAINLESS STEEL PIPE ENQUIRY CONTACT:

COMPANY:KCM SPECIAL STEEL CO.,LTD

MR.BOB LEE

MOB&WHATSAPP:+86-13758498349

SKYPE:BOBO.LEE2

EMAIL:KCMSPECIALSTEEL@OUTLOOK.COM

WEBSITE:WWW.DUPLEXSTAINLESSSTEELPIPES.COM