Description

DUPLEX 2205 STAINLESS STEEL PIPE BRIEF INTRODUCTION

duplex 2205 stainless steel pipe or duplex 2205 pipe with excellent mechanical properties and corrosion resistance, and good weldability, in oil and gas industry, Marine engineering, chemical industry and other industries have a wide range of USES.

The duplex 2205 stainless steel pipe, also known as 2205 duplex pipe, duplex steel pipe 2205, or duplex pipe SAF2205, is a versatile and highly resilient material widely used across various industries. Its unique combination of ferrite and austenite microstructures grants it exceptional mechanical properties, corrosion resistance, and good weldability.

Oil and gas industry at present USES duplex stainless steel material laying of oil and gas pipeline length has more than 850 km, the vast majority of the 2205 duplex stainless steel seamless steel tube (there is also a part of S31803 duplex 2205 stainless steel pipe s, 2507 duplex stainless steel pipe tube);

Due to the corrosive strength of the natural gas medium, the high-pressure duplex 2205 stainless steel pipe line materials.

KCM SPECIAL STEEL OFFERING DUPLEX 2205 STAINLESS STEEL PIPE RELATED PRODUCTS:

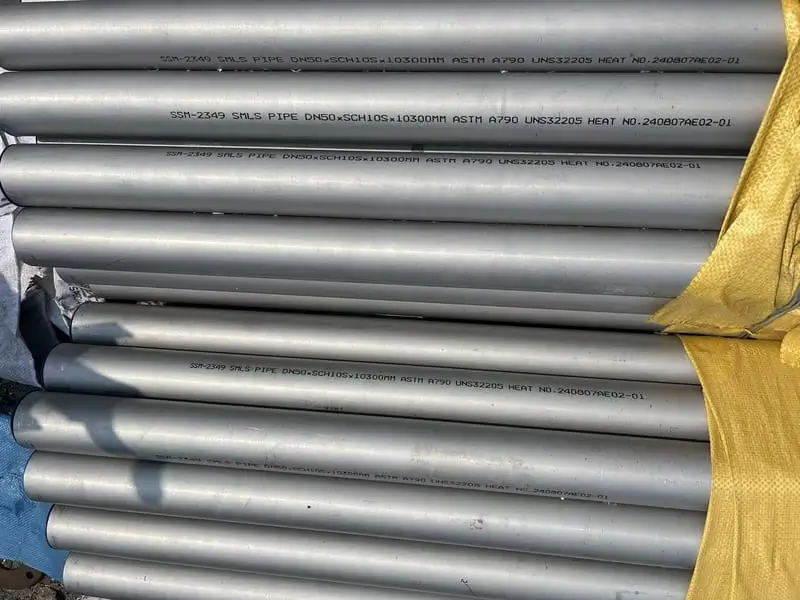

1.duplex 2205 stainless steel pipe seamless

Seamless ASTM A790 UNS S32205 DUPLEX PIPE 2205 Manufacturer and supplier In china, contact us to get High Quality 2205 duplex pipe uns s32205, hurry up for discount price.

2.duplex 2205 stainless steel pipe welded

Welded ASTM A790/ASTM A928 UNS S32205 Duplex Stainless steel pipe 2205 Supplier and Mnaufcturer in china, contact us to get discount price and high quality welded 2205 duplex pipe.

3.duplex 2205 stainless steel tube seamless

4.duplex 2205 stainless steel tube welded

5.duplex 2205 stainless steel pipe fittings

– Elbow: 90°,30°,45°, 60°,180°

– Tee : Equal Tee, Reducing Tee

– Reducer: Concentric reducer,Eccentric reducer

– Cross: 4 ways cross

– Cap: pipe caps

– Stub end

6.duplex 2205 stainless steel pipe flanges

– WN flange: weld neck type

– SW flange: socket weld type

– SO flange: slip on type

– Lap j flange: Lap Joint type

– BL flange: Blind type

7.duplex 2205 stainless steel valves

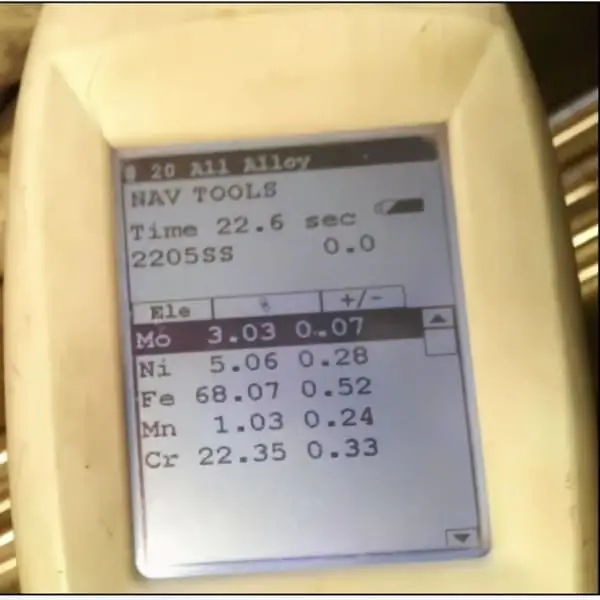

2205 DUPLEX PIPE CHEMICAL COMPOSITION:

| Chemical Composition | Percentage |

|---|---|

| Chromium (Cr) | 21-23% |

| Nickel (Ni) | 4.5-6.5% |

| Molybdenum (Mo) | 2.5-3.5% |

| Nitrogen (N) | 0.08-0.20% |

| Carbon (C) | ≤ 0.030% |

| Manganese (Mn) | ≤ 2.00% |

| Silicon (Si) | ≤ 1.00% |

| Phosphorus (P) | ≤ 0.030% |

| Sulfur (S) | ≤ 0.020% |

ASTM A790 UNS S32205 Duplex Steel Pipe 2205 PMI Test:

ASTM A790 UNS S32205 Duplex Stainless Steel Pipe 2205 Supplier And Manufacturer In China, Contact Us To get discount price and high quality 2205 duplex pipe UNS S32205

DUPLEX 2205 STAINLESS STEEL PIPE ( DUPLEX 2205 PIPE ) PERFOMACE AND COMPARISON

duplex 2205 stainless steel pipe SAF2205 combination of ferrite and austenite is the most beneficial properties, has the very good resistance to chloride stress corrosion cracking, is made up of 21% chromium, 2.5% nitrogen and 4.5% molybdenum nickel alloy consisting of duplex stainless steel.

it is the yield strength of austenitic stainless steel double, this feature enables designers when designing products lose weight, make this kind of alloy has the advantages of more than 316,317L.

Due to the high levels of chrome and molybdenum, the ability to resist spot corrosion and uniform corrosion is excellent. The double phase microstructure ensures that the steel has high tensile strength and high mechanical strength.

Comparison with Other Stainless Steel Grades

Compared to traditional stainless steel grades like 304 and 316, duplex 2205 stainless steel pipe offers several advantages:

1. Higher Strength: Resulting in lighter structures and cost savings.

2. Better Corrosion Resistance: especially in harsh/corrosive environments,such as seawater with high chloride content, acidic wastewater, offshore oil and gas systems maintain structural integrity under extreme conditions, including temperatures ranging from -50°C to 300°C, etc.

3. Cost-Effective: Often more affordable due to reduced material thickness required for equivalent strength.

2205 Duplex Pipe Saf2205 Corrosion Resistance Comparison

| Stainless Steel Grade | Chloride Stress Corrosion Cracking Resistance | Uniform Corrosion Resistance | Tensile Strength |

|---|---|---|---|

| 304 | Moderate | Good | Moderate |

| 316 | Better than 304 | Excellent | Better than 304 |

| 2205 Duplex pipe | Excellent | Excellent | Ve |

Visual Representation: Corrosion Resistance

Duplex 2205 Pipe Conclusion

2205 duplex pipe saf2205 is a high-performance material offering a unique combination of strength, corrosion resistance, and weldability. Its versatility makes it suitable for a wide range of applications across various industries. With in-stock availability and custom manufacturing options, it is a reliable choice for projects requiring robust and resilient piping solutions.

DUPLEX STEEL PIPE 2205 PIPE DIFFERENTS FROM OTHER GRADES STAINLESS STEEL

| Property / Test Condition | Duplex 2205 | 304 | 316L | Remarks |

|---|---|---|---|---|

| Resistance to Corrosion | Excellent | Good | Very Good | General corrosion resistance in various environments |

| Pitting Resistance in Chloride Media | >1000 ppm Cl⁻ | ~47 ppm Cl⁻ | ~152 ppm Cl⁻ | Approximate threshold for pitting initiation at ambient temperature |

| Stress Corrosion Cracking (SCC) Resistance | >1000 h | 47 h | 152 h | In 40% CaCl₂ at 100°C; time to crack initiation |

| PREN | 35.4 | 18.4 | 25.9 | PREN = %Cr + 3.3×%Mo + 16×%N; higher = better pitting resistance |

| Intergranular Corrosion Resistance | Very Good | Good | Good | After sensitization or welding; 316L benefits from low carbon |

| Uniform Corrosion Rate | 0.021 g/(m²·h) | 57 g/(m²·h) | 12.1 g/(m²·h) | In 20% H₂SO₄ at 60°C for 100 h |

| Fatigue Resistance | Very Good | Good | Fair to Good | Due to high strength and microstructure stability |

| Mechanical Properties (after solution annealing: 1020–1100°C, water quenched) | ||||

| – Tensile Strength, Rm (MPa) ≥ | 620 | 515 | 485 | ASTM/EN standard minimums |

| – Yield Strength, Rp0.2 (MPa) ≥ | 450 | 205 | 170 | Duplex 2205 has ~2–2.5× higher yield strength |

| – Elongation, A₅₀ (%) ≥ | 25 | 40 | 40 | Lower ductility due to ferritic phase |

| – Hardness (HB / HRB) ≤ | 290 HB / 30.5 HRB | 187 HB / 90 HRB | 187 HB / 90 HRB | Typical max hardness after annealing |

| Physical Properties (20–100°C) | ||||

| – Thermal Conductivity, W/(m·°C) | 19 | 15 | 15 | Higher in duplex → better heat dissipation |

| – Coefficient of Thermal Expansion, 10⁻⁶/°C | 13.7 | 17.2 | 16.0 | Closer to carbon steel → reduced thermal stress in joints |

| Welding Performance | Excellent | Excellent | Good | • 2205: Low thermal expansion, no preheat/post-weld heat treatment needed; can be welded to 304 with proper filler • 304/316L: Generally weldable; 316L less prone to sensitization than 304 |

| Overall Performance Rating | Excellent | Good | Very Good | 2205 excels in strength + corrosion combo; 316L best among austenitics for chlorides |

✅ Key Takeaways:

- Duplex 2205 offers superior strength, excellent chloride SCC resistance, and high PREN, making it ideal for offshore, desalination, and chemical processing.

- 304 is cost-effective for mild environments but unsuitable for chloride-rich conditions.

- 316L improves over 304 with Mo addition, offering better pitting resistance, but still vulnerable to SCC under high chloride + temperature.

| Property / Feature | Duplex 2205 (UNS S32205/S31803) | 304 (UNS S30400) | 316L (UNS S31603) |

|---|---|---|---|

| Microstructure | Duplex (≈50% ferrite + 50% austenite) | Austenitic | Austenitic |

| Typical Composition | 22% Cr, 5% Ni, 3% Mo, 0.17% N | 18% Cr, 8% Ni | 16–18% Cr, 10–14% Ni, 2–3% Mo |

| PREN | 34–38 | ~18–20 | ~24–26 |

| Yield Strength (MPa) | ≥ 450 | ~200–220 | ~170–200 |

| Tensile Strength (MPa) | ≥ 620 | ~515 | ~485 |

| Elongation (%) | ≥ 25 | ≥ 40 | ≥ 40 |

| Corrosion Resistance | Excellent in chloride environments; high resistance to pitting, crevice, and stress corrosion cracking (SCC) | Good in mild environments; poor in chlorides | Better than 304 due to Mo; moderate chloride resistance |

| Chloride SCC Resistance | Very High | Low | Moderate |

| Magnetic? | Yes (ferritic phase) | No (non-magnetic when annealed) | No (non-magnetic when annealed) |

| Weldability | Good (requires controlled heat input) | Excellent | Excellent |

| Common Applications | Offshore oil & gas, desalination, chemical processing, marine | Food processing, architecture, general purpose | Pharmaceutical, marine hardware, medical, chemical tanks |

| Cost | Higher than 304/316L | Lowest | Moderate |

Note: PREN = %Cr + 3.3×%Mo + 16×%N

Duplex 2205 pipe offers roughly double the yield strength and superior corrosion resistance in aggressive environments compared to 304 and 316L.

DUPLEX PIPE 2205 ( DUPLEX 2205 PIPE ) APPLICATIONS:

Types and Manufacturing Processes

Duplex 2205 stainless steel pipes are manufactured in various forms, including:

1.Seamless and Welded Pipes: Both options available to suit different applications.

2. Shapes: Round, square, and rectangular pipes and tubes.

3. Standard Sizes: Available in stock and can be custom-produced. OD: 6-2400mm WT: 1-70mm

4. Excutive Standards: ASTM A790, ASTM A789, ASTM A928 etc.

2205 Duplex Pipe Saf2205 Manufacturing Processes:

- Seamless Manufacturing: Involves hot rolling or cold drawing to achieve the desired dimensions.

- Welded Manufacturing: Uses automated welding techniques to ensure consistent weld quality.

DUPLEX 2205 STAINLESS STEEL PIPE PACKING & DELIVERY Duplex 2205 Stainless Steel Pipe / Duplex 2205 Pipe In stock

Packaging Options:

1. Plastic Bundles: For protection and ease of handling.

2. Wooden Cases: Provides additional strength and security for international shipments.

3. Additionally, Custom Packaging: As per customer requirements.

Delivery Timeline:

1. In-Stock Items: Typically dispatched within 7 days.

2. Custom Orders: Delivered within 30 days, depending on the complexity and volume.

DUPLEX 2205 STAINLESS STEEL PIPE TYPES

DUPLEX PIPE SAF2205 ( DUPLEX 2205 PIPE ) STANDARD SIZES AVAILABLE IN STOCK AND ARRANGE PRODUCTION.

| INCH | inch sizc (ID) | OD | STANDARD WT | ||||||||||||||

| SCH 5s | SCH 10S | SCH 10 | SCH 20 | SCH 30 | SCH 40 | SCH 60 | SCH 80 | SCH 100 | SCH 120 | SCH 140 | SCH 160 | STD | XS | XXS | |||

| 1/8 | DN6 | 10.3 | – | 1.24 | – | – | – | 1.73 | – | 2.42 | – | – | – | – | 1.73 | 2.41 | – |

| 1/4 | DN8 | 13.7 | – | 1.65 | – | – | – | 2.24 | – | 3.02 | – | – | – | – | 2.24 | 3.02 | – |

| 3/8 | DN10 | 17.1 | – | 1.65 | – | – | – | 2.31 | – | 3.2 | – | – | – | – | 2.31 | 3.2 | – |

| 1/2 | DN15 | 21.3 | 1.65 | 2.11 | – | – | – | 2.77 | – | 3.73 | – | – | – | 4.78 | 2.77 | 3.73 | 7.47 |

| 3/4 | DN20 | 26.7 | 1.65 | 2.11 | – | – | – | 2.87 | – | 3.91 | – | – | – | 5.56 | 2.87 | 3.91 | 7.82 |

| 1 | DN25 | 33.4 | 1.65 | 2.77 | – | – | – | 3.38 | – | 4.55 | – | – | – | 6.35 | 3.38 | 4.55 | 9.09 |

| 1.1/4 | DN32 | 42.2 | 1.65 | 2.77 | – | – | – | 3.56 | – | 4.85 | – | – | – | 6.35 | 3.58 | 4.85 | 9.7 |

| 1.1/2 | DN40 | 48.3 | 1.65 | 2.77 | – | – | – | 3.68 | – | 5.05 | – | – | – | 7.14 | 3.68 | 5.08 | 10.15 |

| 2 | DN50 | 60.3 | 1.65 | 2.77 | – | – | – | 3.91 | – | 5.54 | – | – | – | 8.74 | 3.91 | 5.54 | 11.07 |

| 2.1/2 | DN65 | 73 | 2.11 | 3.05 | – | – | – | 5.16 | – | 7.01 | – | – | – | 9.53 | 5.16 | 7.01 | 14.02 |

| 3 | DN80 | 88.9 | 2.11 | 3.05 | – | , – | – | 5.49 | – | 7.62 | – | – | – | 11.13 | 5.49 | 7.52 | 15.24 |

| 3.1/2 | DN90 | 101.6 | 2.11 | 3.05 | – | – | – | 5.74 | – | 8.08 | – | – | – | – | 5.74 | 8.08 | – |

| 4 | DN100 | 114.3 | 2.11 | 3.05 | – | – | – | 6.02 | – | 8.58 | – | 11.13 | – | 13.49 | 6.02 | 8.56 | 17.12 |

| 5 | DN125 | 141.3 | 2.77 | 3.4 | – | – | – | 6.55 | – | 9.53 | – | 12.7 | – | 15.88 | 6.55 | 9.53 | 18.05 |

| 6 | DN150 | 168.3 | 2.77 | 3.4 | – | – | – | 7.11 | – | 10.97 | – | 14.27 | – | 18.26 | 7.11 | 10.97 | 21.95 |

| 8 | DN200 | 219.1 | 2.77 | 3.76 | – | 6.35 | 7.04 | 8.18 | 10.31 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 8.18 | 12.7 | 22.23 |

| 10 | DN250 | 273.1 | 3.4 | 4.19 | – | 6.35 | 7.8 | 9.27 | 12.7 | 15.09 | 18.26 | 21.44 | 25.4 | 28.58 | 9.27 | 12.7 | 25.4 |

| 12 | DN300 | 323.9 | 3.96 | 4.57 | – | 6.35 | 8.38 | 10.31 | 14.27 | 17.48 | 21.44 | 25.4 | 28.58 | 33.32 | 9.35 | 12.7 | 25.4 |

| 14 | DN350 | 355.5 | 3.96 | 4.78 | 6.35 | 7.92 | 9.53 | 11.13 | 15.09 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | 9.53 | 12.7 | – |

| 16 | DN400 | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.53 | 12.7 | 16.66 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | 9.53 | 12.7 | – |

| 18 | DN450 | 457 | 4.19 | 4.78 | 6.35 | 7.92 | 11.13 | 14.27 | 19.05 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | 9.53 | 12.7 | – |

| 20 | DN500 | 508 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | 15.09 | 20.62 | 26.19 | 32.54 | 38.1 | 44.45 | , 50.01 | 9.53 | 12.7 | – |

| 22 | DN550 | 559 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | – | 22.23 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | 9.53 | 12.7 | – |

| 24 | DN600 | 610 | 5.54 | 6.35 | 6.35 | 9.53 | 14.27 | 17.48 | 24.61 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | 9.53 | 12.7 | – |

| 26 | DN650 | 660 | – | – | 7.92 | 12.7 | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 28 | DN700 | 711 | – | – | 7.92 | 12.7 | 15.88 | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 30 | DN750 | 762 | 6.35 | 7.92 | 7.92 | 12.7 | 15.88 | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 32 | DN800 | 813 | – | – | 7.92 | 12.7 | 15.88 | 17.48 | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 34 | DN850 | 864 | – | – | 7.92 | 12.7 | 15.88 | 17.48 | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 36 | DN900 | 914 | – | – | 7.92 | 12.7 | 15.88 | 19.05 | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 38 | DN950 | 965 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 40 | DN1000 | 1015 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 42 | DN1050 | 1067 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 44 | DN1100 | 1118 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 46 | DN1150 | 1188 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 48 | DN1200 | 1219 | – | – | – | – | – | – | – | – | – | – | – | – | |||

DUPLEX 2205 STAINLESS STEEL PIPE ENQUIRY CONTACTS:

COMPANY:KCM SPECIAL STEEL CO.,LTD

SALES:MR.BOB LEE

WEB:WWW.DUPLEXSTAINLESSSTEELPIPES.COM

EMAIL:KCMSPECIALSTEEL@OUTLOOK.COM

SKYPE:BOBO.LEE2

MOB&WHATSAPP:+86-13758498349

Duplex Pipe 2205 FAQ With US:

Q1: What are the main advantages of duplex 2205 stainless steel pipe?

A1: The main advantages include high tensile strength, excellent corrosion resistance, and good weldability.

Q2: In which industries is duplex 2205 pipe commonly used?

A2: It is commonly used in the oil and gas, marine engineering, chemical, pulp and paper, and water treatment industries.

Q3: Are duplex pipe SAF2205 available in seamless and welded types?

A3: Yes, both seamless and welded types are available.

The Evolution of Duplex 2205 Stainless Steel Pipe

1. Origins and Early Development (1970s–1980s)

Duplex 2205 (UNS S32205) emerged in the 1970s as a response to industrial demands for corrosion-resistant alloys. Its dual-phase microstructure—combining austenite and ferrite—provided superior strength and chloride resistance compared to traditional stainless steels like 316L. By the 1980s, the oil crisis accelerated offshore drilling projects, where 2205 pipes became critical for seawater-handling systems due to their low corrosion rates in marine environments.

(Example table embedded in text:

Corrosion Rate Comparison (1980s):

| Material | Corrosion Rate (mm/year) |

|---|---|

| 316L | 0.12 |

| Duplex 2205 | 0.03 |

| Data from seawater exposure tests13. ) |

2. Standardization and Industrial Adoption (1990s)

The 1990s saw ASTM formalize UNS S32205 standards, enabling global adoption. Chemical plants utilized 2205 pipes for acid storage, leveraging its pitting resistance equivalence (PREN >34). Innovations in welding techniques, such as argon shielding, addressed early joint brittleness issues, further solidifying its role in oil refineries and desalination plants.

3. 21st-Century Applications and Innovations

By the 2000s, uns s32205 pipes dominated 15% of the stainless steel market. Key milestones included:

Desalination: Middle Eastern plants used uns s32205 for brine circulation systems, where sand-particle erosion tests showed a 70% lower mass loss than 316L.

Energy Transition: Biofuel refineries adopted uns s32205 for ethanol processing due to its resistance to stress corrosion cracking.

Advanced Manufacturing: Laser welding and 3D-printed fittings reduced production costs by 40%.

(Example timeline chart:

Global 2205 Demand Growth (2000–2025):

2000: 50,000 tons

2010: 120,000 tons

2025: 300,000 tons (projected)

Sources: Industrial production reports.

4. Modern Challenges and Future Prospects

Despite competition from super duplex grades (e.g., 2507), 2205 remains cost-effective for marine infrastructure. Recent studies highlight its resilience in extreme conditions:

A 2023 Australian offshore pipeline with 2205 components survived 30 years of saltwater exposure with <5% wall thickness loss.

Nano-coatings enhanced its pH tolerance, expanding use in hydrogen storage systems.

Conclusion

From offshore rigs to renewable energy, duplex 2205 stainless steel pipes exemplify material science’s role in solving industrial challenges. Its blend of durability, affordability, and adaptability ensures continued relevance in a resource-constrained world.

UNS S32205 Duplex Pipe UNS S31803: Fueling Global Economic Growth

1. Energy Revolution: Powering Offshore Oil & Gas

UNS S32205 duplex pipe has redefined offshore energy infrastructure. Its chloride resistance enables durable subsea pipelines, cutting maintenance costs by 30% compared to carbon steel.

(Table 1: Cost Savings with Duplex 2205 Pipe vs. Alternatives)

| Material | Lifetime Cost (per km) | Maintenance Frequency |

|---|---|---|

| Carbon Steel | $8M | Every 2 years |

| 316L Stainless | $10M | Every 5 years |

| Duplex S32205 | $6.5M | Every 10 years |

2. Industrial Efficiency: Chemical & Desalination Sectors

Duplex 2205 pipe’s pitting resistance (PREN >34) makes it ideal for corrosive environments. Saudi Arabia’s Jubail Desalination Plant uses 2205 duplex pipes to process 1.5M m³/day of brine, reducing downtime by 40%. Similarly, BASF’s acid storage tanks doubled lifespan with UNS S32205, boosting output by $200M/year.

(Chart 1: Global Duplex Pipe Demand by Sector [2024])

Oil & Gas: 45%

Desalination: 25%

Chemicals: 20%

Renewables: 10%

3. Sustainable Infrastructure: Green Energy & Transport

Duplex uns s32205 pipe underpins green transitions. Hydrogen pipelines in Germany’s H2Global initiative use 2205 duplex pipes to prevent embrittlement. Wind turbine foundations in the North Sea employ duplex S32205 for saltwater corrosion resistance, cutting replacement costs by 50%.

4. Economic Ripple Effects: Jobs & Trade

The duplex pipe UNS S32205 industry supports 2M jobs worldwide. Outokumpu’s Alabama mill, producing 100K tons/year of 2205 duplex pipe, revitalized local economies. Meanwhile, India’s duplex pipe exports grew 18% annually, earning $3B in 2023.

(Table 2: Top 5 Duplex Pipe Exporters [2023])

| Country | Export Value ($B) | Market Share |

|---|---|---|

| China | 4.2 | 35% |

| Germany | 2.1 | 18% |

| Japan | 1.8 | 15% |

| USA | 1.5 | 12% |

| India | 1.0 | 8% |

5. Challenges & Future Outlook

Despite competition from super duplex grades, 2205 duplex pipe remains cost-effective. Innovations like AI-driven welding robots and recycled duplex alloys aim to cut production costs by 25% by 2030. The UN forecasts duplex pipe demand to grow 7% yearly, driven by Africa’s energy projects and Asia’s urbanization.

Conclusion

From oil rigs to hydrogen highways, duplex 2205 stainless steel pipe (UNS S32205) has become a linchpin of global industrial growth. By balancing durability, sustainability, and affordability, it fuels economies while paving the way for a resilient future.

How to Correctly Apply UNS S31803 Duplex Pipe UNS S32205/2205: A Technical Guide

1. Understanding Duplex 2205 Pipe Properties

Duplex 2205 stainless steel pipe (UNS S32205) combines austenitic and ferritic phases, offering high strength (550 MPa yield) and corrosion resistance. Its PREN (Pitting Resistance Equivalent Number) exceeds , making it ideal for chloride-rich environments. Key applications include offshore oil platforms, desalination plants, and chemical processing.

(Table 1: Key Properties of UNS S32205 Duplex Pipe)

| Property | Value |

|---|---|

| Yield Strength | ≥550 MPa |

| PREN | 34–38 |

| Operating Temperature | -50°C to 300°C |

| Chloride Tolerance | ≤20,000 ppm |

2. Material Selection Guidelines

Select duplex 2205 pipe based on environment and stress. For seawater systems, prioritize PREN >35. Avoid using duplex uns s32205 pipe in sulfuric acid (>10%) or caustic soda (>50%) without protective coatings. Verify compliance with ASTM A790 or A928 standards.

(Flowchart: Material Selection Process)

①、Environment: Identify chloride, pH, and temperature.

②、Stress: Calculate mechanical load (axial, bending).

③、Standards: Match to ASTM/ISO certifications.

④、Cost: Compare lifecycle expenses.

3. Design & Fabrication Best Practices

3.1 Welding UNS S32205 Duplex Pipe

Use TIG/GTAW with 22.8.3L filler metal (AWS A5.9). Maintain interpass temperatures below 150°C to avoid sigma phase formation. Post-weld, ensure 30–50% ferrite content via feritscope testing.

(Table 2: Welding Parameters for Duplex Pipe UNS S32205)

| Parameter | Requirement |

|---|---|

| Heat Input | 0.5–1.5 kJ/mm |

| Interpass Temperature | <150°C |

| Shielding Gas | 98% Ar + 2% N₂ |

3.2 Cutting & Forming

Avoid plasma cutting—opt for laser or waterjet to prevent heat-affected zone (HAZ) embrittlement. For bends, limit cold-forming to 15% strain to retain microstructure integrity.

4. Installation & Corrosion Prevention

4.1 Piping Layout

Isolate 2205 duplex pipe from carbon steel using dielectric unions to prevent galvanic corrosion. Support pipes every 2–3 meters to minimize stress.

(Chart 1: Corrosion Risk Mitigation Steps)

①、Galvanic Isolation: Use non-conductive gaskets.

②、Cathodic Protection: Apply impressed current in submerged zones.

③、Coatings: Epoxy for splash zones.

4.2 Testing & Inspection

Conduct hydrostatic tests at 1.5× working pressure. Use dye penetrant or ultrasonic testing (UT) to detect weld defects. For chloride exposure, validate via ASTM G48 Method A (ferric chloride test).

5. Maintenance & Lifecycle Management

5.1 Routine Checks

Inspect duplex pipe UNS S32205 annually for pitting or crevice corrosion. Clean deposits with pH-neutral solutions—avoid abrasive tools.

(Table 3: Maintenance Schedule for Duplex 2205 Pipe)

| Task | Frequency | Tools/Methods |

|---|---|---|

| Visual Inspection | Biannual | Boroscope |

| Wall Thickness Test | Annual | Ultrasonic gauge |

| Coating Repair | As needed | Epoxy spray |

5.2 End-of-Life Recycling

Recycle uns s32205 duplex pipe via electric arc furnaces (EAF). Chromium and nickel recovery rates exceed 95%, aligning with circular economy goals.

6. Case Study: Offshore Platform Success

A North Sea platform replaced carbon steel with duplex uns s32205 pipe for seawater cooling. After 10 years, inspections showed <0.1 mm/year corrosion—50% lower than 316L. Maintenance costs dropped by $1.2M annually.

(Graph 1: Cost Comparison Over 10 Years)

①、Carbon Steel: $15M (replacement + downtime)

②、Duplex 2205: $8M (initial + maintenance)

7. Common Pitfalls to Avoid

①、Overheating: Excessive welding heat degrades ferrite-austenite balance.

②、Wrong Filler Metal: Using 316L filler causes joint weakness.

③、Poor Ventilation: Trapped chlorides accelerate crevice corrosion.

Conclusion

Mastering the use of duplex 2205 stainless steel pipe (UNS S32205) requires attention to design, welding, and maintenance. By adhering to ASTM standards and leveraging its corrosion resistance, industries can achieve safer, longer-lasting infrastructure.