Description

1.Al-6xn Stainless Steel Pipe UNS N08367: Properties, Applications, and Comparisons

1. Introduction to AL-6XN Stainless Steel Pipe UNS N08367/1.4529

1.1 Material Classification

AL-6XN Stainless Steel Pipe UNS N08367, EN 1.4529 is a super austenitic stainless steel combining high corrosion resistance, strength, and cost-effectiveness. It bridges the gap between conventional stainless steels (e.g., 316L) and nickel-based alloys, making it ideal for aggressive environments.

1.2 Historical Background

Developed in the 1980s, AL-6XN addressed corrosion challenges in offshore oil, chemical processing, and marine industries. Its nitrogen-enhanced design optimizes pitting resistance and mechanical performance.

2. AL-6XN Stainless Steel Pipe UNS N08367 Chemical Composition

2.1 Key Alloying Elements

| Element | Content (%) | Role |

| Cr | 20.0–22.0 | Enhances oxidation resistance |

| Ni | 23.5–25.5 | Stabilizes austenitic structure |

| Mo | 6.0–7.0 | Resists chloride-induced corrosion |

| N | 0.18–0.25 | Boosts strength and pitting resistance |

2.2 Trace Elements

- C ≤ 0.03%: Reduces carbide precipitation risks.

- Cu ≤ 0.75%: Improves acid resistance.

3. UNS N08367 Stainless Steel Pipe 1.4529 Al-6xn Physical and Mechanical Properties

3.1 Physical Characteristics

| Property | Value |

| Density | 8.24 g/cm³ |

| Melting Point | 1320–1400°C |

| Thermal Conductivity | 25.7 W/m·K (100°C) |

3.2 Mechanical Performance

- Tensile Strength: ≥650 MPa.

- Yield Strength: ≥295 MPa.

- Elongation: ≥35%.

Property Value Density 8.24 g/cm³56 Melting Point 1320–1400°C34 Thermal Conductivity 25.7 W/m·K (100°C)56

4. Al-6xn Stainless Steel Pipe 1.4529 UNS N08367 Corrosion Resistance

4.1 Chloride Environments

AL-6XN exhibits PREN ≥ 45, outperforming 316L (PREN 26) in seawater and brine. It resists pitting even in 6% FeCl₃ at 60°C.

4.2 Acid and Alkali Resistance

- Sulfuric Acid: Corrosion rate <0.1 mm/year at 60% concentration (80°C).

- Phosphoric Acid: Suitable for concentrated solutions up to 120°C.

5. 1.4529 Stainless Steel Pipe Uns N08367 Al-6xn Manufacturing and Fabrication

5.1 Heat Treatment

- Solution Annealing: 1065–1150°C with rapid cooling.

- Stress Relieving: Optional for welded components.

5.2 Welding Methods

| Technique | Filler Material | Post-Weld Treatment |

| TIG/MIG | ERNiCrMo-348 | Not required26 |

| SMAW | ENiCrMo-335 | Local annealing2 |

AL-6XN (UNS N08367/1.4529) is a super austenitic stainless steel pipe with high Ni/Cr/Mo/N content, offering superior resistance to chloride corrosion, pitting, and stress cracking, ideal for marine, chemical, and industrial applications

6. Al-6xn Super Austenitic Stainless Steel Pipe UNS N08367 Industrial Applications

6.1 Oil & Gas

- Subsea Pipelines: Resists H₂S and CO₂ corrosion.

- Heat Exchangers: Handles sour gas cooling.

6.2 Marine and Desalination

- Seawater Reverse Osmosis (SWRO): High-pressure tubing.

- Shipbuilding: Propeller shafts and ballast systems.

7.Performance of UNS N08367 (AL-6XN/1.4529) Stainless Steel Pipes in Marine and Desalination Systems

7.1 Superior Chloride Resistance

UNS N08367 (AL-6XN/1.4529) stainless steel pipes exhibit PREN ≥ 45, far exceeding conventional 316L (PREN 26) in seawater and brine environments12. This alloy resists pitting and crevice corrosion even in 6% FeCl₃ at 60°C, making it ideal for marine applications.

7.2 Mechanical Strength for High-Pressure Systems

| Property | UNS N08367 | 316L |

| Tensile Strength | ≥650 MPa | 485 MPa |

| Yield Strength | ≥295 MPa | 170 MPa |

| Elongation | ≥35% | 40% |

The nitrogen-enhanced design of Al-6XN stainless steel pipe ensures structural integrity in high-pressure desalination systems like reverse osmosis (RO) membranes.

7.3 Corrosion Performance in Seawater

- Seawater Corrosion Rate: <0.01 mm/year.

- Stress Corrosion Cracking (SCC) Resistance: No cracking observed in 40% MgCl₂ at 120°C.

Stainless steel pipe 1.4529 is widely used in seawater intake pipelines, heat exchangers, and brine pumps due to its durability.

7.4 Applications in Desalination Plants

7.4.1 Reverse Osmosis (RO) Systems

- High-Pressure Tubing: UNS N08367 stainless steel pipe handles pressures up to 80 bar in RO membranes15.

- Brine Discharge Pipes: Resists chloride-induced erosion at elevated temperatures26.

7.4.2 Marine Engineering

- Shipbuilding: Propeller shafts, ballast systems, and offshore platform components15.

- Heat Exchangers: Maintains efficiency in seawater cooling loops.

7.5 Cost-Effective Alternative to Nickel Alloys

| Parameter | UNS N0836715 | Titanium2 |

| Material Cost | 50% lower | High |

| Lifespan | 20+ years | 25+ years |

Al-6XN stainless steel pipe offers comparable performance to titanium in moderate-temperature seawater systems at half the cost.

7.6 Summary

UNS N08367 (AL-6XN/1.4529) stainless steel pipes deliver exceptional chloride resistance, high mechanical strength, and cost efficiency in marine and desalination environments. Their nitrogen and molybdenum-rich composition ensures longevity in aggressive seawater and high-pressure RO systems, outperforming traditional alloys like 316L.

FAQ

Q1: Why is UNS N08367 preferred in seawater desalination?

A: Its PREN ≥ 45 and high Mo (6–7%) resist chloride-induced corrosion, ensuring reliability in RO systems.

Q2: Can UNS N08367 replace titanium in marine heat exchangers?

A: Yes, for temperatures ≤80°C, it offers similar corrosion resistance at lower costs.

Q3: What welding methods suit UNS N08367 pipes?

A: TIG welding with ERNiCrMo-3 filler ensures joint integrity without post-weld treatment.

8.UNS N08367 Stainless Steel Pipe Al-6xn 1.4529 Comparative Analysis

8.1 AL-6XN vs. 316L Stainless Steel

AL-6XN (UNS N08367/1.4529) and 316L (UNS S31603) are both austenitic stainless steels, but their performance diverges significantly in aggressive environments. AL-6XN contains elevated chromium (20-22%), nickel (23.5-25.5%), molybdenum (6-7%), and nitrogen (0.18-0.25%), enabling superior resistance to pitting, crevice corrosion, and stress corrosion cracking in chloride-rich media like seawater or chemical processing systems12. In contrast, 316L’s lower alloy content (16-18% Cr, 10-14% Ni, 2-3% Mo) limits its threshold to ~1,000 ppm chlorides, whereas AL-6XN withstands over 10,000 ppm.

Mechanically, AL-6XN offers 40% higher ASME allowable stress than 316L due to nitrogen strengthening, reducing material thickness requirements in high-pressure applications. Both alloys exhibit good weldability, but AL-6XN requires ERNiCrMo-3 filler to retain corrosion resistance in welded joints.

While 316L remains cost-effective for mild corrosive environments (food processing, architectural), AL-6XN’s lifecycle cost advantages emerge in marine infrastructure, flue gas desulfurization units, or nuclear plant cooling systems where 316L would rapidly degrade. For projects demanding extreme durability without nickel-alloy pricing, AL-6XN bridges the gap between standard stainless steels and premium corrosion-resistant alloys

| Parameter | AL-6XN | 316L |

| Cost | 2× higher | Lower |

| Lifespan | 3–5× longer longer | Limited to mild conditions |

7.2 AL-6XN vs. Inconel 625

AL-6XN (UNS N08367/1.4529) and Inconel 625 (UNS N06625) serve distinct roles in corrosive environments. AL-6XN, a super-austenitic stainless steel, achieves corrosion resistance through high chromium (20-22%), nickel (23.5-25.5%), molybdenum (6-7%), and nitrogen (0.18-0.25%) content, excelling in chloride-rich media like seawater and flue gas desulfurization systems. Inconel 625, a nickel-chromium-molybdenum alloy, contains ≥58% nickel and 8-10% molybdenum, offering superior performance in high-temperature oxidizing environments and concentrated acidic solutions.

Mechanically, AL-6XN provides 40% higher ASME allowable stress than 316L stainless steel due to nitrogen strengthening, while Inconel 625 maintains exceptional tensile strength (≥758 MPa) and creep resistance above 600°C. Both alloys exhibit good weldability, though AL-6XN requires ERNiCrMo-3 filler to preserve corrosion resistance in welded joints.

Cost-effectiveness differs significantly: AL-6XN bridges the gap between standard stainless steels and nickel alloys, priced 30-50% lower than Inconel 62534. For applications under 200°C with chloride exposure (marine piping, desalination), AL-6XN delivers optimal lifecycle value12. Inconel 625 remains preferred for extreme conditions (nuclear reactors, aerospace exhausts) where thermal stability (>800°C) and multi-acid resistance outweigh cost concerns46. Material selection hinges on balancing temperature demands, chloride concentrations, and budget constraints.

| Parameter | AL-6XN | Inconel 625 |

| Cost | 40–50% lower | High |

| Chloride Resistance | Comparable | Superior |

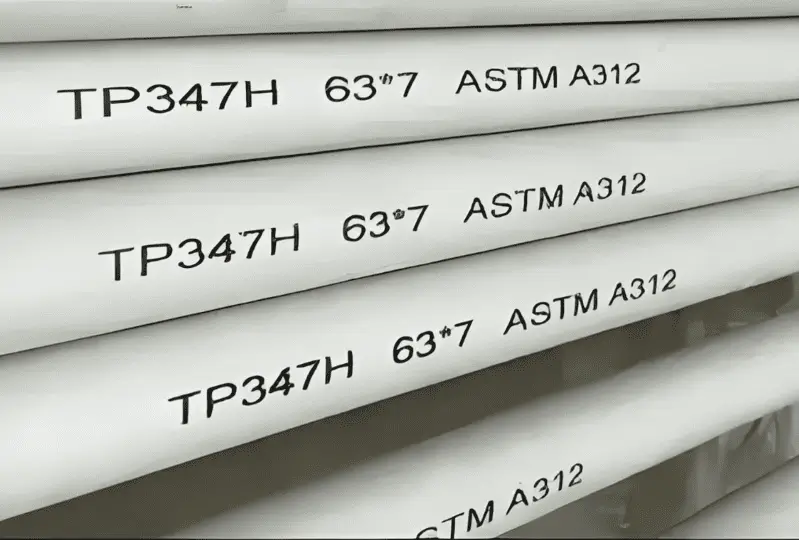

9. Al6xn Stainless Steel Pipe 1.4529 UNS N08367 Standards and Certifications

9.1 ASTM/ASME Specifications

- ASTM B688: Seamless pipes for corrosive service. reference from astm.org

- ASME SB676: Welded tubing.

9.2 ISO and EN Compliance

- EN 1.4501: European designation.

- NACE MR0175: Approved for sour gas applications.

10. Conclusion

AL-6XN/UNS N08367 stainless steel pipe offers superior corrosion resistance, high strength, and cost efficiency for extreme environments in oil, chemical, and marine industries. Its nitrogen-enhanced austenitic structure ensures longevity where traditional alloys fail.

11. Frequently Asked Questions (FAQ) About 1.4529 Stainless Steel Pipe UNS N08367 AL6XN

Q1: What makes AL-6XN superior to 316L?

A: AL-6XN’s higher Mo (6–7%) and N (0.18–0.25%) enhance chloride resistance and strength, extending service life.

Q2: Can AL-6XN replace titanium in seawater systems?

A: Yes, for temperatures ≤80°C and moderate pressures, AL-6XN offers comparable performance at 50% lower cost.

Q3: What welding methods are optimal for AL-6XN?

A: TIG welding with ERNiCrMo-3 filler ensures corrosion-resistant joints without post-weld heat treatment.

Q4: Is AL-6XN suitable for sulfuric acid storage?

A: Yes, it resists corrosion in concentrated H₂SO₄ up to 60% at 80°C

12. Al-6xn Stainless Steel Pipe UNS N08367 1.4529 Available In Stock Or For New Production Size Chart

| NPS(Inch) | DN | OD(mm) | SCH5S | SCH10S | SCH40S/STD | SCH80S/XS | SCH160/XXS |

|---|---|---|---|---|---|---|---|

| 1/2 | 15 | 21.3 | 1.65 | 2.11 | 2.77 | 3.7 | 7.47 |

| 3/4 | 20 | 26.7 | 1.65 | 2.11 | 2.87 | 3.914 | 7.82 |

| 1 | 25 | 33.4 | 1.65 | 2.774 | 3.38 | 4.554 | 9.09 |

| 1½ | 40 | 48.3 | 1.65 | 2.774 | 3.68 | 5.084 | 10.15 |

| 2 | 50 | 60.3 | 1.65 | 2.774 | 3.91 | 5.544 | 11.07 |

| 2½ | 65 | 73.0 | 3.05 | 5.164 | 5.16 | 7.01 | 14.02 |

| 3 | 80 | 88.9 | 3.05 | 5.494 | 5.49 | 7.62 | 15.24 |

| 4 | 100 | 114.3 | 3.05 | 6.027 | 6.02 | 8.56 | 17.12 |

| 6 | 150 | 168.3 | 3.4 | 7.117 | 7.11 | 10.97 | 21.95 |

| 8 | 200 | 219.1 | 3.76 | 8.18 | 8.18 | 12.707 | 22.2 |

| 10 | 250 | 273.0 | 4.19 | 9.27 | 9.27 | 15.097 | 25.4 |

| 12 | 300 | 323.9 | 4.57 | 9.537 | 9.53 | 17.48 | 27.79 |

| 14 | 350 | 355.6 | 6.35 | 9.537 | 9.53 | 15.09 | 25.4 |

| 16 | 400 | 406.4 | 6.35 | 9.537 | 9.53 | 16.66 | 26.19 |

| 18 | 450 | 457.2 | 6.35 | 11.137 | 11.13 | 19.05 | 29.36 |

| 20 | 500 | 508.0 | 6.35 | 12.7 | 12.7 | 20.62 | 32.54 |

| 24 | 600 | 609.6 | 6.35 | 12.7 | 12.7 | 24.61 | 36.53 |

13. Al-6xn Stainless Steel Pipe UNS N08367 1.4529 Supplier and Manufacturer Contact:

Company: KCM Special Steel Co.,Ltd

Contact : Mr.Bob

Mob & whatsapp:+86-13758498349

Email: kcmspecialsteel@outlook.com

Web: www.duplexstainlesssteelpipes.com