Description

UNS N08904 / 904L STAINLESS STEEL PIPE BRIEF INTRODUCTION

904l stainless steel pipe (00 cr20ni25mo4. 5 cu) has better corrosion resistance of austenitic stainless steel, because of adding 1.5% copper, for reducing acid,such as sulfuric acid and phosphoric acid also has very good corrosion resistance, in addition, has the characteristics of low carbon in welding purposes.

NAME:904L STAINLESS STEEL PIPE SEAMLESS PIPE OD:6-720MM SEAMLESS PIPE W.T:1-50MM

OTHER NAME: 904L SUPER STAINLESS STEEL PIPE WELDED PIPE OD:12-2500MM WELDED PIPE W.T:1-40MM

904L STAINLESS STEEL PIPE CATALOGUE:

904L STAINLESS STEEL PIPE DIRECTORY

1. product introduction

2. features

3. weight

4. chemical composition

5. production process

6. surface

7. applications

8. available sizes in stock and arrange production

9. contacts

What is 904L Stainless Steel Pipe

904L (N08904, 1.4539) super austenitic stainless steel pipe contains 14.0-18.0% chromium, 24.0-26.0% nickel, and 4.5% molybdenum. 904L Super Austenitic Stainless Steel Pipe is a low-carbon, high nickel, molybdenum austenitic stainless and acid resistant steel, which is a proprietary material introduced from the French company H. S. It has excellent activation passivation transformation ability, excellent corrosion resistance, and good corrosion resistance in non oxidizing acids such as sulfuric acid, acetic acid, formic acid, and phosphoric acid.

It also has good resistance to pitting corrosion in neutral chloride ion media, as well as good resistance to crevice corrosion and stress corrosion. Suitable for various concentrations of sulfuric acid below 70 ℃, it is resistant to any concentration and temperature of acetic acid under normal pressure, and has good corrosion resistance in mixed acids of formic acid and acetic acid.

SS904L STAINLESS STEEL PIPE PRODUCT INTRODUCTION:

Corrosion resistance of 904L stainless steel pipe s

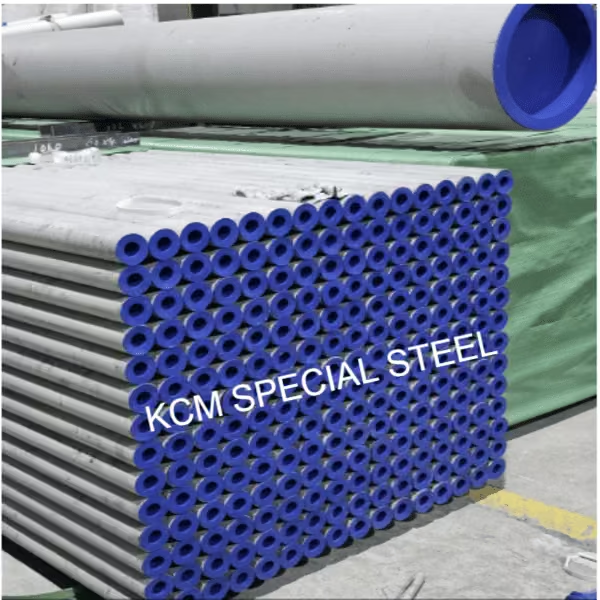

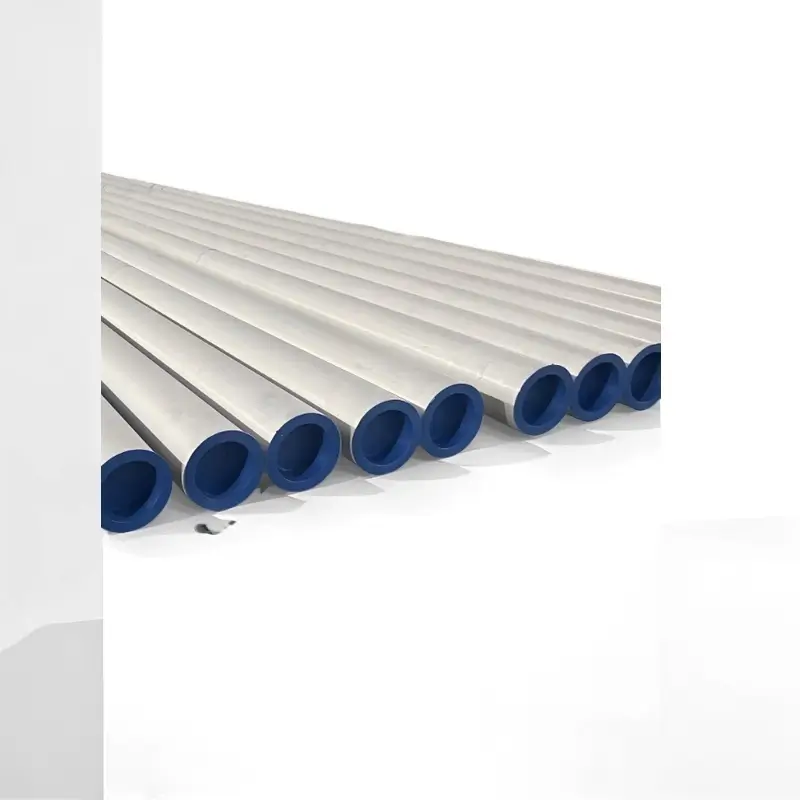

Stainless steel seamless pipe, welded pipe , square pipe. Its specification: the outer diameter of the seamless tube is 6-720mm, the wall is 1-50mm. Welding tube outer diameter 12-2500mm, wall thickness 1-40 MM.

904L STAINLESS STEEL PIPE UNS N08904 FEATURES:

Because of the low carbon content of 904L (0.020%), there is no carbon deposition in the case of general heat treatment and welding. This eliminates the risk of the corrosion of the crystals that occur after heat treatment and welding. Due to high chromium nickel molybdenum content and the addition of copper, 904L stainless steel pipes

Even in reductive environments such as sulfuric acid and formic acid can be passivated. High nickel content also has low corrosion speed in active condition. the concentration range of 0 ~ 98% pure sulfuric acid, the use of 904 l temperature can be as high as 40 ℃. In pure phosphoric acid in the range of 0 ~ 85%, its corrosion resistance is very good. for the industrial phosphoric acid produced by wet process, the corrosion resistance of impurities has a strong effect.

904L Stainless Steel Pipe Has Better Corrosion Resistance

Among all kinds of phosphoric acid,904L stainless steel pipe s are superior to normal stainless steel tubes. In the highly oxidized nitric acid, the corrosion resistance is low compared to the high alloy steel, which is non-molybdenum. The hydrochloric acid, the use of 904L stainless steel pipe is limited to a low concentration of 1-2%. In this concentration range. The corrosion resistance of 904L stainless steel is better than conventional stainless steel. The 904L stainless steel pipe has a high resistance to point corrosion.

It is also good to resist the corrosion resistance of the chloride solution. The high nickel content of the 904L stainless steel pipe decreases the corrosion speed of the pit and crack. Ordinary austenitic stainless steel in the temperature above 60 ℃, in a rich chloride environment sensitive to stress corrosion may be, by improving the nickel content of stainless steel, can reduce the sensitization. Because of the high content of nickel, 904 l stainless steel tube in chloride solution, concentration of hydroxide solution and rich hydrogen sulfide environment, has the very high resistance to stress corrosion cracking ability.

AL – 904L is designed for harsh environment corrosion condition of a low carbon content, high alloying austenitic stainless steel, 316 l and 317 l has better corrosion resistance, both price and performance, cost-effective high. By adding 1.5 percent of the copper, it is highly resistant to acid, such as sulfuric acid and phosphoric acid.

904L STAINLESS STEEL PIPE WEIGHT:

Weight (kg) = (OD-WT)*WT*0.0251*Length(m)

Stainless steel ratio: the chromium stainless steel takes 7.75t/M3 / M3 / M3, 7.87 t/M3

The formula of theoretical weight of stainless steel plate

Steel theory weight length (mm) x width (mm) x thickness (mm) x density = weight (kg)

ASTM B677 UNS N08904 904L Seamless Pipe Weight Chart

| NPS | Outside Diameter (OD) | Wall Thickness (WT) | Weight | Weight | |||

| in | mm | in | mm | Sched | kg/Mtr | Lb/ft | |

| 1/2″ | 0.840 | 21 | 0.109 | 2.769 | 40 STD | 1.268 | 0.851 |

| 0.147 | 3.734 | 80 STD | 1.621 | 1.088 | |||

| 3/4″ | 1.050 | 27 | 0.113 | 2.870 | 40 STD | 1.684 | 1.131 |

| 0.154 | 3.912 | 80 STD | 2.195 | 1.474 | |||

| 1″ | 1.315 | 33 | 0.133 | 3.378 | 40 STD | 2.501 | 1.679 |

| 0.179 | 4.547 | 80 STD | 3.325 | 2.172 | |||

| 1 1/4″ | 1.660 | 42 | 0.140 | 3.556 | 40 STD | 3.385 | 2.273 |

| 0.191 | 4.851 | 80 STD | 4.464 | 2.997 | |||

| 1 1/2″ | 1.900 | 48 | 0.145 | 3.683 | 40 STD | 4.048 | 2.718 |

| 0.200 | 5.080 | 80 STD | 5.409 | 3.361 | |||

| 2″ | 2.375 | 60 | 0.154 | 3.912 | 40 STD | 5.441 | 3.653 |

| 0.218 | 5.537 | 80 STD | 7.480 | 5.022 | |||

| 2 1/2″ | 2.875 | 73 | 0.203 | 5.516 | 40 STD | 8.629 | 5.793 |

| 0.276 | 7.010 | 80 STD | 11.411 | 7.661 | |||

| 3″ | 3.500 | 89 | 0.216 | 5.486 | 40 STD | 11.284 | 7.576 |

| 0.300 | 7.620 | 80 STD | 15.272 | 10.253 | |||

| 4″ | 4.500 | 114 | 0.237 | 6.020 | 16.073 | 10.790 | |

| 0.337 | 8.560 | 22.318 | 14.983 | ||||

| 6″ | 6.625 | 168 | 0.188 | 4.775 | 19.252 | 12.924 | |

| 0.203 | 5.516 | 20.739 | 13.923 | ||||

| 0.219 | 5.563 | 22.318 | 14.983 | ||||

| 0.250 | 6.350 | 25.354 | 17.021 | ||||

| 0.280 | 7.112 | 40 STD | 58.263 | 18.974 | |||

| 0.312 | 7.925 | 31.334 | 21.036 | ||||

| 0.375 | 9.525 | 37.285 | 25.031 | ||||

| 0.432 | 10.973 | 80 XHY | 42.561 | 28.573 | |||

| 0.500 | 12.700 | 48.719 | 32.708 | ||||

| 8″ | 8.625 | 219 | 0.188 | 4.775 | 25.233 | 16.940 | |

| 0.203 | 5.156 | 27.198 | 18.259 | ||||

| 0.219 | 5.563 | 29.286 | 19.661 | ||||

| 0.250 | 6.350 | 20 | 33.308 | 22.361 | |||

| 0.277 | 7.036 | 30 | 36.786 | 24.696 | |||

| 0.322 | 8.179 | 40 | 42.352 | 28.554 | |||

| 0.375 | 9.525 | 49.216 | 33.041 | ||||

| 0.406 | 10.312 | 60 | 53.085 | 35.638 | |||

| 0.500 | 12.700 | 80 XHY | 64.627 | 43.388 | |||

| 10″ | 10.750 | 273 | 0.188 | 4.775 | 31.588 | 21.207 | |

| 0.219 | 5.563 | 36.689 | 24.631 | ||||

| 0.250 | 6.350 | 20 | 41.759 | 28.035 | |||

| 0.307 | 7.798 | 30 | 51.002 | 34.240 | |||

| 0.344 | 8.738 | 56.946 | 38.231 | ||||

| 0.365 | 9.271 | 40 STD | 63.301 | 40.483 | |||

| 0.438 | 11.125 | 71.852 | 48.238 | ||||

| 0.500 | 12.700 | 60 XHY | 81.530 | 54.735 | |||

| 0.594 | 15.088 | 80 | 95.969 | 64.429 | |||

| 12″ | 12.750 | 324 | 0.188 | 4.775 | 37.570 | 25.222 | |

| 0.219 | 5.563 | 43.657 | 29.309 | ||||

| 0.250 | 6.350 | 49.713 | 33.375 | ||||

| 0.281 | 7.137 | 55.739 | 37.420 | ||||

| 0.312 | 7.925 | 61.735 | 41.445 | ||||

| 0.375 | 9.525 | 73.824 | 49.562 | ||||

| 0.406 | 10.312 | 79.727 | 53.525 | ||||

| 0.500 | 12.700 | 97.438 | 65.415 | ||||

| 0.562 | 14.275 | 108.966 | 73.154 | ||||

| 14″ | 14.000 | 356 | 0.188 | 4.775 | 41.308 | 27.732 | |

| 0.219 | 5.563 | 48.012 | 32.233 | ||||

| 0.250 | 6.350 | 20 | 54.685 | 36.713 | |||

| 0.281 | 7.137 | 61.327 | 41.172 | ||||

| 0.312 | 7.925 | 67.939 | 45.611 | ||||

| 0.375 | 9.525 | STD | 81.281 | 54.568 | |||

| 0.438 | 11.125 | 40 | 94.498 | 63.441 | |||

| 0.500 | 12.700 | XHY | 107.381 | 72.090 | |||

| 0.625 | 15.875 | 132.983 | 89.278 | ||||

| 16” | 16.000 | 406 | 0.188 | 4.775 | 47.290 | 21.748 | |

| 0.219 | 5.563 | 54.980 | 36.910 | ||||

| 0.250 | 6.350 | 10 | 62.639 | 42.053 | |||

| 0.281 | 7.137 | 70.268 | 47.174 | ||||

| 0.312 | 7.925 | 20 | 77.866 | 52.275 | |||

| 0.344 | 8.738 | 85.677 | 57.519 | ||||

| 0.375 | 9.525 | 30 STD | 93.213 | 62.578 | |||

| 0.438 | 11.125 | 108.433 | 72.797 | ||||

| 0.500 | 12.700 | 40 XHY | 123.289 | 82.770 | |||

| 18″ | 18.000 | 457 | 0.219 | 5.563 | 61.948 | 41.588 | |

| 0.250 | 6.350 | 70.593 | 47.393 | ||||

| 0.281 | 7.137 | 79.208 | 53.176 | ||||

| 0.312 | 7.925 | 20 | 87.792 | 58.939 | |||

| 0.375 | 9.525 | STD | 105.144 | 70.588 | |||

| 0.438 | 11.125 | 30 | 122.369 | 82.152 | |||

| 0.500 | 12.700 | XHY | 139.198 | 93.450 | |||

| 0.562 | 14.275 | 40 | 155.904 | 104.666 | |||

| 0.625 | 15.875 | 172.754 | 115.978 | ||||

| 20″ | 20.000 | 508 | 0.250 | 6.350 | 78.547 | 52.733 | |

| 0.282 | 7.163 | 88.458 | 59.386 | ||||

| 0.312 | 7.925 | 97.719 | 65.604 | ||||

| 0.375 | 9.525 | 20 STD | 117.075 | 78.598 | |||

| 0.438 | 11.125 | 136.305 | 91.508 | ||||

| 0.500 | 12.700 | 30 XHY | 155.106 | 104.130 | |||

| 0.594 | 15.088 | 40 | 183.378 | 123.110 | |||

| 0.625 | 15.875 | 192.640 | 129.328 | ||||

| 0.688 | 17.475 | 211.368 | 141.901 | ||||

| 24″ | 24.000 | 610 | 0.250 | 6.350 | 94.456 | 63.413 | |

| 0.281 | 7.137 | 106.029 | 71.183 | ||||

| 0.312 | 7.925 | 117.573 | 18.932 | ||||

| 0.375 | 9.525 | 20 STD | 140.938 | 64.618 | |||

| 0.438 | 11.125 | 164.176 | 110.219 | ||||

| 0.500 | 12.700 | XHY | 186.923 | 125.490 | |||

| 0.625 | 15.875 | 232.410 | 156.028 | ||||

| 0.688 | 17.475 | 40 | 255.148 | 171.293 | |||

| 0.750 | 19.050 | 277.401 | 186.233 | ||||

| 30″ | 30.000 | 762 | 0.250 | 6.350 | 118.318 | 79.433 | |

| 0.281 | 7.137 | 132.851 | 89.189 | ||||

| 0.312 | 7.925 | 10 | 147.353 | 98.925 | |||

| 0.375 | 9.525 | STD | 176.731 | 118.648 | |||

| 0.438 | 11.125 | 205.983 | 138.286 | ||||

| 0.500 | 12.700 | 20 XHY | 234.647 | 157.530 | |||

| 0.625 | 15.875 | 30 | 292.066 | 196.078 | |||

| 0.688 | 17.475 | 320.817 | 215.380 | ||||

| 0.750 | 19.050 | 348.988 | 234.293 | ||||

| 36″ | 36.000 | 914 | 0.250 | 6.350 | 142.180 | 95.453 | |

| 0.281 | 7.137 | 159.672 | 107.196 | ||||

| 0.312 | 7.925 | 10 | 177.133 | 118.918 | |||

| 0.375 | 9.525 | STD | 215.525 | 142.678 | |||

| 0.438 | 11.125 | 247.790 | 166.353 | ||||

| 0.500 | 12.700 | 20 XHY | 282.372 | 198.570 | |||

| 0.625 | 15.875 | 351.723 | 236.128 | ||||

| 0.688 | 17.475 | 386.487 | 259.467 | ||||

| 0.750 | 19.050 | 420.576 | 282.353 | ||||

| 42″ | 42.000 | 1067 | 0.312 | 7.925 | 206.914 | 138.911 | |

| 0.375 | 9.525 | STD | 248.319 | 166.708 | |||

| 0.500 | 12.700 | XHY | 33.097 | 221.610 | |||

| 0.750 | 19.050 | 492.163 | 330.413 | ||||

| 48″ | 48.000 | 1219 | 0.375 | 9.525 | STD | 284.112 | 190.738 |

| 0.438 | 11.125 | 331.404 | 222.487 | ||||

| 0.500 | 12.700 | XHY | 377.822 | 253.650 | |||

| 0.750 | 19.050 | 563.750 | 378.473 | ||||

| 0.875 | 22.225 | 655.969 | 440.383 | ||||

904L STAINLESS STEEL PIPE CHEMICAL COMPOSITION:

ITEM | C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

ASTM | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.00~2.00 |

904L Stainless Steel Pipe Pressure Rating

904L Pipe Pressure Ratings at Elevated Temperatures As per ASME B31.3

| TEMPERATURE | COMPARISON TO OTHER HIGH TEMPERATURE PIPE | ||||

|---|---|---|---|---|---|

| °F | °C | ALLOY 254 | UNS C69100 TEMPER TF00 | TYPE 904L | ALLOY 825 |

| 200 | 93 | 0.88 | 1.00 | 0.82 | 1.00 |

| 300 | 149 | 0.79 | 1.00 | 0.74 | 0.95 |

| 400 | 204 | 0.73 | 0.96 | 0.68 | 0.90 |

| 500 | 260 | 0.69 | 0.63 | 0.87 | |

| 600 | 315 | 0.66 | 0.58 | 0.84 | |

| 700 | 371 | 0.64 | 0.56 | 0.81 | |

| 800 | 426 | 0.79 | |||

Schedule 40 Alloy 904L Stainless Steel Pipe thickness and dimensions

| NOMINAL SIZE [INCHES] | OUTSIDE DIAMETER (OD) [INCHES] | OUTSIDE DIAMETER (OD) [MM] | WALL THICKNESS [INCHES] | WALL THICKNESS [MM] | WEIGHT [LB/FT] | WEIGHT [KG/M] |

|---|---|---|---|---|---|---|

| 1/8″ NPS 6 | 0.41 | 10.3 | 0.068 | 1.73 | 0.24 | 0.37 |

| 1/4″ NPS 8 | 0.54 | 13.7 | 0.088 | 2.24 | 0.42 | 0.63 |

| 3/8″ NPS 10 | 0.68 | 17.1 | 0.091 | 2.31 | 0.57 | 0.84 |

| 1/2″ NPS 15 | 0.84 | 21.3 | 0.109 | 2.77 | 0.85 | 1.27 |

| 3/4″ NPS 20 | 1.05 | 26.7 | 0.113 | 2.87 | 1.13 | 1.69 |

| 1″ NPS 25 | 1.32 | 33.4 | 0.133 | 3.38 | 1.68 | 2.5 |

| 1 1/4″ NPS 32 | 1.66 | 42.2 | 0.14 | 3.56 | 2.27 | 3.39 |

| 1 1/2″ NPS 40 | 1.9 | 48.3 | 0.145 | 3.68 | 2.72 | 4.05 |

| 2″ NPS 50 | 2.375 | 60.3 | 0.154 | 3.91 | 3.65 | 5.44 |

| 2 1/2″ NPS 65 | 2.875 | 73.0 | 0.203 | 5.16 | 5.79 | 8.63 |

| 3″ NPS 80 | 3.5 | 88.9 | 0.216 | 5.49 | 7.58 | 11.29 |

| 3 1/2″ NPS 90 | 4.0 | 101.6 | 0.226 | 5.74 | 9.11 | 13.57 |

| 4″ NPS 100 | 4.5 | 114.3 | 0.237 | 6.02 | 10.79 | 16.07 |

| 5″ NPS 125 | 5.563 | 141.3 | 0.258 | 6.55 | 14.62 | 21.77 |

| 6″ NPS 150 | 6.625 | 168.3 | 0.28 | 7.11 | 18.97 | 28.26 |

| 8″ NPS 200 | 8.625 | 219.1 | 0.322 | 8.18 | 28.55 | 42.55 |

| 10″ NPS 250 | 10.75 | 273.0 | 0.365 | 9.27 | 40.48 | 60.31 |

| 12″ NPS 300 | 12.75 | 323.8 | 0.406 | 10.31 | 53.52 | 79.73 |

| 14″ NPS 350 | 14.0 | 355.6 | 0.437 | 11.13 | 54.57 | 94.55 |

| 16″ NPS 400 | 16.0 | 406.4 | 0.5 | 12.7 | 82.77 | 123.3 |

| 18″ NPS 450 | 18.0 | 457.0 | 0.562 | 14.27 | 104.67 | 155.8 |

| 20″ NPS 500 | 20.0 | 508.0 | 0.594 | 15.09 | 123.11 | 183.42 |

| 24″ NPS 600 | 24.0 | 610.0 | 0.688 | 17.48 | 171.29 | 255.41 |

| 32″ NPS 800 | 32.0 | 813.0 | 0.688 | 17.48 | 230.08 | 342.91 |

Notes:

1. ASME/ ANSI B36.10/ B36.19 – Imperial Units

2. 1 cm2 = 10-4 m2 = 0.155 in2

3. 1 kg = 2.2046 lb

4. 1 m = 3.28 ft

Stainless Steel 904L Seamless Pipe Chemical Composition

| ELEMENT | MIN | MAX |

|---|---|---|

| C | – | 0.2 |

| Mn | – | 2 |

| Ni | 23 | 28 |

| Cr | 19 | 23 |

| S | – | 0.3 |

| Mo | 4 | 5 |

| N | – | 0.1 |

| Cu | 1 | 2 |

| P | – | 0.03 |

| Si | – | 0.7 |

SUS 904L Pipe Mechanical Properties

| TEMPER | ANNEALED | |

|---|---|---|

| Tensile Rm | 71 | ksi (min) |

| Tensile Rm | 490 | MPa (min) |

| R.p. 0.2% Yield | 32 | ksi (min) |

| R.p. 0.2% Yield | 220 | MPa (min) |

| Elongation (2” or 4D gl) | 35 | % (min) |

Stainless Steel 904L Pipe Physical Properties

| Specific Heat (0-100°C) | 450 | J.kg-1.°K-1 |

| Thermal Conductivity | 11.5 | W.m -1.°K-1 |

| Thermal Expansion | 15.8 | mm/m/°C |

| Modulus Elasticity | 190 | GPa |

| Electrical Resistivity | 9.52 | μohm/cm |

| Density | 7.95 | g/cm3 |

Equivalent Material of Type 904L Stainless Steel

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 904L | N08904 | 904S13 | X1NiCrMoCu25-20-5 | 1.4539 | – | – | SUS 890L |

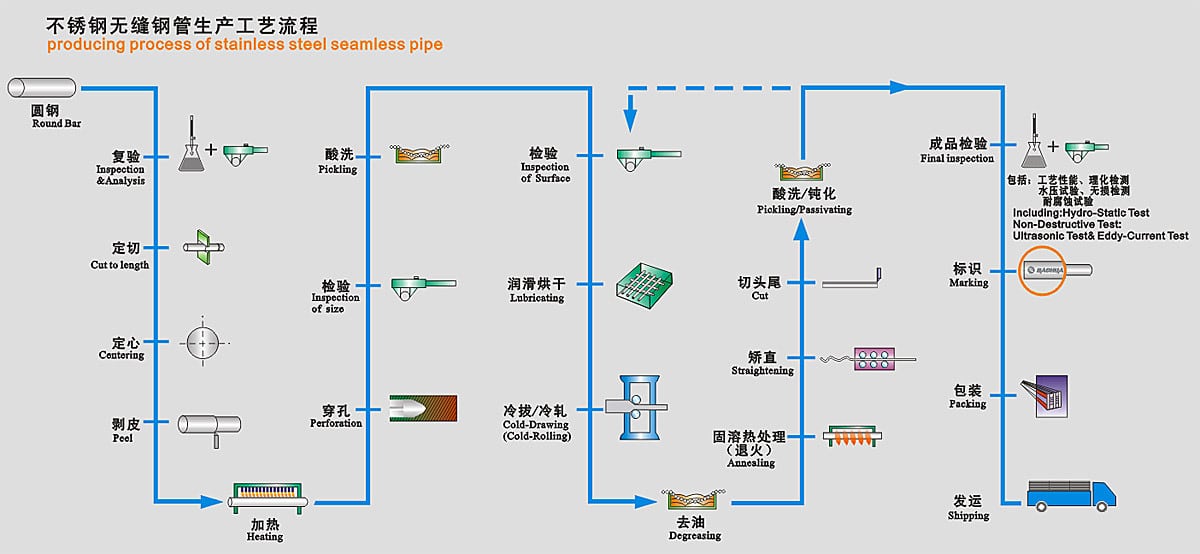

SS904L STAINLESS STEEL PIPE SEAMLESS PRODUCTION PROCESS

904L STAINLES STEEL PIPE SUPPLIERS,MANUFACTURERS,STOCKHOLDER, CONTACT US TO GET FANTASTIC PRICE AND HIGH QUALITY 904L STAINLESS STEEL PIPE UNS N08904 SEAMLESS

904L STAINLESS STEEL PIPE WELDED PRODUCTION PROCESS

UNS N08904 / 904L STAINLESS STEEL PIPE SUPPLIERS,MANUFACTURER ,KCM SPECIAL STEEL, CONTACT US TO GET HIGH QUALITY UNS N08904 STAINLESS STEEL PIPE 904L

ASTM A312 TP904L STAINLESS STEEL PIPE UNS N08904 SURFACE:

SEAMLESS ASTM A312 904L STAINLES STEEL PIPE SUPPLIERS,MANUFACTURERS,STOCKHOLDER, CONTACT US TO GET FANTASTIC PRICE AND HIGH QUALITY UNS N08904 STAINLESS STEEL PIPE TP904L

904L STAINLESS STEEL PIPE APPLICATIONS:

SHIPBUILDING INDUSTRY

CHEMICAL INDUSTRY

WATER INDUSTRY

STEEL INDSUTRY

POWER STATION INDUSTRY

OIL&GAS INDSUCTRY

IN MARINE INDUSTRY

OFFSHORE&ONSHORE INDSUTRY

FOOD INDUSTRY

MEICAL INDSTURY

904L STAINLESS STAINLESS PIPE AVAILABLE SIZES IN STOCK AND ARRANGE PRODUCTION:

| INCH | inch sizc (ID) | OD | STANDARD WALL THICKNESS | ||||||||||||||

| SCH 5s | SCH 10S | SCH 10 | SCH 20 | SCH 30 | SCH 40 | SCH 60 | SCH 80 | SCH 100 | SCH 120 | SCH 140 | SCH 160 | STD | XS | XXS | |||

| 1/8 | DN6 | 10.3 | – | 1.24 | – | – | – | 1.73 | – | 2.42 | – | – | – | – | 1.73 | 2.41 | – |

| 1/4 | DN8 | 13.7 | – | 1.65 | – | – | – | 2.24 | – | 3.02 | – | – | – | – | 2.24 | 3.02 | – |

| 3/8 | DN10 | 17.1 | – | 1.65 | – | – | – | 2.31 | – | 3.2 | – | – | – | – | 2.31 | 3.2 | – |

| 1/2 | DN15 | 21.3 | 1.65 | 2.11 | – | – | – | 2.77 | – | 3.73 | – | – | – | 4.78 | 2.77 | 3.73 | 7.47 |

| 3/4 | DN20 | 26.7 | 1.65 | 2.11 | – | – | – | 2.87 | – | 3.91 | – | – | – | 5.56 | 2.87 | 3.91 | 7.82 |

| 1 | DN25 | 33.4 | 1.65 | 2.77 | – | – | – | 3.38 | – | 4.55 | – | – | – | 6.35 | 3.38 | 4.55 | 9.09 |

| 1.1/4 | DN32 | 42.2 | 1.65 | 2.77 | – | – | – | 3.56 | – | 4.85 | – | – | – | 6.35 | 3.58 | 4.85 | 9.7 |

| 1.1/2 | DN40 | 48.3 | 1.65 | 2.77 | – | – | – | 3.68 | – | 5.05 | – | – | – | 7.14 | 3.68 | 5.08 | 10.15 |

| 2 | DN50 | 60.3 | 1.65 | 2.77 | – | – | – | 3.91 | – | 5.54 | – | – | – | 8.74 | 3.91 | 5.54 | 11.07 |

| 2.1/2 | DN65 | 73 | 2.11 | 3.05 | – | – | – | 5.16 | – | 7.01 | – | – | – | 9.53 | 5.16 | 7.01 | 14.02 |

| 3 | DN80 | 88.9 | 2.11 | 3.05 | – | , – | – | 5.49 | – | 7.62 | – | – | – | 11.13 | 5.49 | 7.52 | 15.24 |

| 3.1/2 | DN90 | 101.6 | 2.11 | 3.05 | – | – | – | 5.74 | – | 8.08 | – | – | – | – | 5.74 | 8.08 | – |

| 4 | DN100 | 114.3 | 2.11 | 3.05 | – | – | – | 6.02 | – | 8.58 | – | 11.13 | – | 13.49 | 6.02 | 8.56 | 17.12 |

| 5 | DN125 | 141.3 | 2.77 | 3.4 | – | – | – | 6.55 | – | 9.53 | – | 12.7 | – | 15.88 | 6.55 | 9.53 | 18.05 |

| 6 | DN150 | 168.3 | 2.77 | 3.4 | – | – | – | 7.11 | – | 10.97 | – | 14.27 | – | 18.26 | 7.11 | 10.97 | 21.95 |

| 8 | DN200 | 219.1 | 2.77 | 3.76 | – | 6.35 | 7.04 | 8.18 | 10.31 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 8.18 | 12.7 | 22.23 |

| 10 | DN250 | 273.1 | 3.4 | 4.19 | – | 6.35 | 7.8 | 9.27 | 12.7 | 15.09 | 18.26 | 21.44 | 25.4 | 28.58 | 9.27 | 12.7 | 25.4 |

| 12 | DN300 | 323.9 | 3.96 | 4.57 | – | 6.35 | 8.38 | 10.31 | 14.27 | 17.48 | 21.44 | 25.4 | 28.58 | 33.32 | 9.35 | 12.7 | 25.4 |

| 14 | DN350 | 355.5 | 3.96 | 4.78 | 6.35 | 7.92 | 9.53 | 11.13 | 15.09 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | 9.53 | 12.7 | – |

| 16 | DN400 | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.53 | 12.7 | 16.66 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | 9.53 | 12.7 | – |

| 18 | DN450 | 457 | 4.19 | 4.78 | 6.35 | 7.92 | 11.13 | 14.27 | 19.05 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | 9.53 | 12.7 | – |

| 20 | DN500 | 508 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | 15.09 | 20.62 | 26.19 | 32.54 | 38.1 | 44.45 | , 50.01 | 9.53 | 12.7 | – |

| 22 | DN550 | 559 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | – | 22.23 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | 9.53 | 12.7 | – |

| 24 | DN600 | 610 | 5.54 | 6.35 | 6.35 | 9.53 | 14.27 | 17.48 | 24.61 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | 9.53 | 12.7 | – |

| 26 | DN650 | 660 | – | – | 7.92 | 12.7 | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 28 | DN700 | 711 | – | – | 7.92 | 12.7 | 15.88 | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 30 | DN750 | 762 | 6.35 | 7.92 | 7.92 | 12.7 | 15.88 | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 32 | DN800 | 813 | – | – | 7.92 | 12.7 | 15.88 | 17.48 | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 34 | DN850 | 864 | – | – | 7.92 | 12.7 | 15.88 | 17.48 | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 36 | DN900 | 914 | – | – | 7.92 | 12.7 | 15.88 | 19.05 | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 38 | DN950 | 965 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 40 | DN1000 | 1015 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 42 | DN1050 | 1067 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 44 | DN1100 | 1118 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 46 | DN1150 | 1188 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 48 | DN1200 | 1219 | – | – | – | – | – | – | – | – | – | – | – | – | |||

904L STAINLESS STEEL PIPE ORDERS’ CONTACTS

COMPANY: KCM SPECIAL STEEL CO.,LTD

WEB: WWW.DUPLEXSTAINLESSSTEELPIPES.COM

EMAIL: KCMSPECIALSTEEL@OUTLOOK.COM

CONTACT: MR.BOB LEE

MOB&WHATSAPP: +86-13758498349