Description

321 STAINLESS STEEL PIPE BRIEF INTRODUCTION

321 stainless steel pipe is an austenitic stainless steel pipe primarily composed of chromium (17-19%), nickel (9-12%), and titanium (≥5×C content), designed to enhance high-temperature stability and intergranular corrosion resistance.

321 stainless steel pipe standardized internationally as S32100 (ASTM), SUS321 (JIS), or TP321 (ASME), and widely used in petroleum, chemical, food processing, and mechanical engineering industries due to its durability under thermal stress (up to 816°C). The titanium addition stabilizes the alloy against chromium carbide precipitation during welding or high-temperature exposure

SS321 TP321 AISI321 321 Stainless Steel Pipe Supplier and Manufacturer in China, Contact us to get high quality and Low price Stainless Steel 321 Pipe Seamless And Welded.

321 Stainless Steel Pipe Applications

321 stainless steel Pipe is a versatile material widely used in industries requiring corrosion resistance, high-temperature stability, and mechanical durability. Its primary applications include:

Petroleum & Natural Gas

High-temperature pipelines, heat exchangers, and drilling equipment due to its resistance to thermal stress (up to 816°C) and intergranular corrosion .Chemical Processing

Reactors, acid-resistant containers, and corrosive fluid transport systems, leveraging its resistance to organic/inorganic acids and oxidation in aggressive environments

Food & Pharmaceutical Industries

Hygienic processing equipment and storage tanks, benefiting from its non-reactive surface and ease of sterilization .

Automotive Exhaust systems and fuel lines, where it withstands high-temperature gases and resists oxidation .

Medical & Construction Surgical instruments and structural components, valued for its durability, anti-microbial properties, and load-bearing capacity .

Nuclear & Power Generation

Reactor components and boiler systems (e.g., superheaters, steam pipes) due to its radiation resistance and thermal creep strength .

The titanium-stabilized alloy (Ti ≥5×C content) ensures minimized carbide precipitation during welding or prolonged high-temperature exposure, making it critical for safety-critical applications

The titanium-stabilized alloy (Ti ≥5×C content) ensures minimized carbide precipitation during welding or prolonged high-temperature exposure, making it critical for safety-critical applications

321 STAINLESS STEEL PIPE 321 CONTAINS METERIAL 321,321H, WHICH IS GOST STANDARD METERIAL GRADE IS 08X18H10T, LET ME INTRODUCE IT AS FOLLOWS:

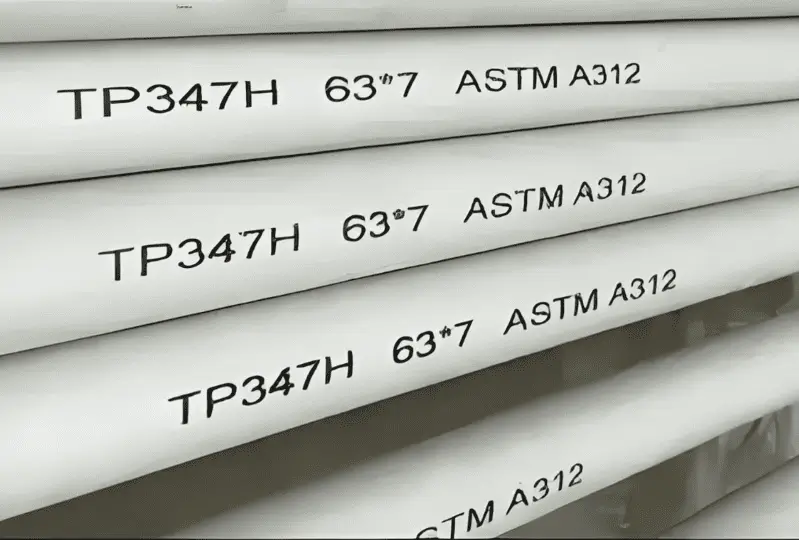

1: 321 stainless steel pipe. Seamless steel tube (ASTM A312/213 TP321/321H use in the manufacture of various structural low intermediate pressure

boiler superheated steam pipe, water pipe and locomotive boiler superheated steam pipe, pipes,

small pipe and arch brick works of high quality carbon structural steel hot rolling and cold drawing (rolling) seamless steel tube.

2: 321 stainless steel pipe: mainly use in the manufacture of high pressure and over pressure steam boiler pipes, etc. With high quality carbon structural steel,

alloy steel and stainless heat resistant steel seamless steel tube, these often under high temperature and high pressure boiler tube,

tube in high temperature flue gas and steam will happen under the action of oxidation and corrosion, so the steel pipe with high rupture strength,

high oxidation resistance, and have good organizational stability, hydraulic prop.

3: 321 stainless steel tubes are a kind of steel: like 304 321 316 317 310, etc

4: alloy steel pipe steel number 15MoG, 20MoG, 12CrMoG, 15CrMoG, 12Cr2MoG, 12CrMoVG, 12Cr3MoVSiTiB, etc.

In addition to the chemical composition and mechanical properties of 1Cr18Ni9 and 1Cr18Ni11Nb high pressure boilers, the hydraulic pressure test should be done by root, and the test will be expanded.

321 stainless steel pipe s deliver in heat treatment. In addition, there are certain requirements for the microstructure, grain size and decarburizing layer of finished steel tube.

5.A seamless steel tube for geological drilling and oil drilling. In order to ascertain the structure of underground strata, groundwater, oil, natural gas and mineral resources, the drill use to drill Wells.

Mining more from drilling, oil and gas geological drilling in oil drilling in seamless steel pipe is the main drilling equipment, mainly including core tube, core tube, casing, drill pipe, etc.

Because the drill pipe has to drill deep into the depth of several thousand meters, the 1cr5mo alloy pipe.

6: working condition is very complex, drill pipe under pull, pressure, bending, torsion and uneven impact load stress, but also by mud,

rocks and wear, therefore, requires tubing must have sufficient strength, hardness, wear resistance and impact toughness, steel pipe steel with

“DZ” pinyin “(geology) plus number one on behalf of the said steel yield point, common steel grade DZ45 MNB 45, 50 mn; DZ50 40 mn2, 40 mn2si; DZ55 40 mn2mo, 40 MNVB;

40 mnmob DZ60, DZ65 27 mnmovb. All steel pipes are delivered in heat treatment.

Oil cracking pipe: pipe, heat exchanger tube and tube for oil refinery. The products are made from high quality carbon steel (10, 20),

alloy steel (12CrMo, 15CrMo), heat resistant steel (12Cr2Mo, 15Cr5Mo), stainless steel (1Cr18Ni9, 1Cr18Ni9Ti).

7: 321 stainless steel pipe: with all kinds of stainless steel hot rolling and cold rolling stainless steel tube,

pipe widely use in petroleum, chemical industry equipment and various USES of the stainless steel structural parts,

in addition to ensure that the chemical composition and mechanical properties,

all steel pipe use as the fluid under pressure to keep the water pressure test. All special steel pipes shall be guaranteed according to the regulations.

welded pipe also call welding tube, is made by bending and forming with steel or steel strip. The weld pipe divide into straight seam welded pipe and spiral welded pipe.

According to the application divide into general welded pipe, galvanized welded pipe, oxygen blowing metric welded pipe, welded pipe, wire casing, roller tube, deep well pump tube, 321 stainless steel tube, automobile use pipe, transformer, electric welding thin wall pipe, welded pipe and spiral welded pipe.

8; The stainless steel tube is a long strip of steel with hollow section and no seam.

The pipe has a hollow section and use as a conduit for conveying fluids such as oil, gas, gas, water and certain solid materials.

The seamless pipe divide into hot rolled tube, cold rolled tube, cold tube, extruded tube and top tube 16Mn seamless tube

321 STAINLESS STEEL PIPE OUT DIAMETER TOLERENCE AND TOLERENCE GRADE

GRADE | OD TOLERENCE |

D1 | ±1.5%,MIN±0.75 mm |

D2 | ±1.0% , MIN ±0.50 mm |

D3 | ±0.75%.MIN±0.30 mm |

D4 | ±0.50%。MIN±0.10 mm |

THE DIFFERENCE AND CONNECTION BETWEEN 304 AND 321 STAINLESS STEEL PIPE.

The 321 stainless steel pipe is a brand of stainless steel manufactured according to the ASTM standard. The stainless steel tube is equivalent to the 0Cr19Ni9 (0Cr18Ni9) stainless steel pipe in our country. 304 contains 18% of chromium and 8% nickel.

321 stainless steel pipe tube, the most widely use for stainless steel, the equipment for food, general chemical equipment, and the atomic energy industry.

The 321 stainless steel pipe tube, a versatile stainless steel tube that widely use to make equipment and parts that require good overall performance (corrosion resistance and molding).

321 stainless steel pipe tube, the most widely use stainless steel, heat resistant steel. Use in food production equipment, chemical equipment, nuclear power, etc.

321 stainless steel pipe tube chemical composition specification C Si Mn P S Cr Ni (nickel) Mo

SUS304 less than or less than 0.08 is less than or equal to 1.00 or less than 0.03, or less than 0.05, or 0.03, 18.00-20.00, 8.25 ~ 10.50 –

In air or chemical corrosion resistant to corrosion medium of a kind of high alloy steel. stainless steel is a beautiful surface and corrosion resistant performance is good, need not after surface treatment, such as color of plating and the surface of the stainless steel inherent performance, used in a variety of steel a, often called stainless steel. It represents the performance of 13 chrome steel, 18-8 chrome nickel steel.

From the perspective of metallography analysis, because the stainless steel containing chromium and make the surface form very thin chromium film, the film is isolated from intrusion in the steel corrosion of oxygen. To maintain the corrosion resistance inherent in stainless steel, steel must contain more than 12 percent chromium.

321 stainless steel pipe seamless steel pipe (ASTM A312/213 TP321 ) use in the manufacture of various structural low intermediate pressure boiler superheated steam pipe, water pipe and locomotive boiler superheated steam pipe, pipes, small pipe and arch brick works of high quality carbon structural steel hot rolling and cold drawing (rolling) seamless steel tube.

321 stainless steel pipe mainly use in the manufacture of high pressure and over pressure steam boiler pipes, etc.

321 stainless steel pipe With high quality carbon structural steel.

alloy steel and stainless heat resistant steel seamless steel tube, the boiler tube by the party under high temperature and high pressure pipe and works in high temperature flue gas and steam will happen under the action of oxidation and corrosion. so the steel pipe with high rupture strength, high oxidation resistance, and have good organizational stability, hydraulic prop.

The stainless steel pipe has a steel number:

There are 20G, 20MnG and 25MnG steel. 304 stainless steel pipe.

The alloy structural steel number 15MoG, 20MoG, 12CrMoG, 15CrMoG, 12Cr2MoG, 12CrMoVG, 12Cr3MoVSiTiB, etc.

Rust resistant steel use in 1Cr18Ni9 and 1Cr18Ni11Nb high pressure boiler tube except for the chemical composition and mechanical properties, the water pressure test should be done by the root, which should be expanded and flat test.

The stainless steel tube shall deliver in heat treatment.

additionally, there are certain requirements for the microstructure, grain size and decarburizing layer of finished steel tube. A seamless steel tube for geological drilling and oil drilling.

In order to ascertain the structure of underground strata, groundwater, oil, natural gas and mineral resources, the drill use to drill Wells

Chemical composition of ASTM A312 TP321 stainless steel pipe 321

| Element | Composition (%) | Note |

|---|---|---|

| Carbon (C) | ≤0.08 | Maximum content |

| Silicon (Si) | ≤1.00 | |

| Manganese (Mn) | ≤2.00 | |

| Phosphorus (P) | ≤0.045 | |

| Sulfur (S) | ≤0.030 | |

| Chromium (Cr) | 17.00 – 19.00 | |

| Nickel (Ni) | 9.00 – 12.00 | |

| Titanium (Ti) | 5×(C+N) – 0.70 | Formula-based calculation |

| Molybdenum (Mo) | ≤0.10 (if present) | Optional additive |

Stainless steel 321 pipe Excutive Standard

ASTM, ASME, EN, DIN, GB, GOST, JIS

321 STAINLESS STEEL PIPE SEAMLESS AND WELDED AVAILABLE SIZES TO ARRANGE PRODUCTION:

| Dimensions for ASME/ANSI Standards | Unit:mm | ||||||||||||

| B16.9 B16.28 B36.10 | |||||||||||||

| Nominal pipe Size(NPS) | Outside Diameter | Nominal Wall Thickness | |||||||||||

| Sch5s | SCH10S | Sch20 | Sch30 | Sch40 | STD | Sch80 | XS | Sch160 | XXS | ||||

| 8 | 1/4 | 13.7 | 0.54 | – | 1.65 | – | 1.85 | 2.24 | 2.24 | 3.02 | 3.02 | – | – |

| 10 | 3/8 | 17.1 | 0.675 | – | 1.65 | – | 1.85 | 2.31 | 2.31 | 3.20 | 3.20 | – | – |

| 15 | 1/2 | 21.3 | 0.84 | 1.65 | 2.11 | – | 2.41 | 2.77 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 |

| 20 | 3/4 | 26.7 | 1.05 | 1.65 | 2.11 | – | 2.41 | 2.87 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 |

| 25 | 1 | 33.4 | 1.32 | 1.65 | 2.77 | – | 2.90 | 3.38 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 |

| 32 | 1.1/4 | 42.2 | 1.66 | 1.65 | 2.77 | – | 2.97 | 3.56 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 |

| 40 | 1.1/2 | 48.3 | 1.90 | 1.65 | 2.77 | – | 3.18 | 3.68 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 |

| 50 | 2 | 60.3 | 2.38 | 1.65 | 2.77 | – | 3.18 | 3.91 | 3.91 | 5.54 | 5.54 | 8.74 | 11.07 |

| 65 | 2.1/2 | 73.0 | 2.88 | 2.11 | 3.05 | – | 4.78 | 5.16 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 |

| 80 | 3 | 88.9 | 3.50 | 2.11 | 3.05 | – | 4.78 | 5.49 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 |

| 90 | 3.1/2 | 101.6 | 4.00 | 2.11 | 3.05 | – | 4.78 | 5.74 | 5.74 | 8.08 | 8.08 | – | – |

| 100 | 4 | 114.3 | 4.50 | 2.11 | 3.05 | – | 4.78 | 6.02 | 6.02 | 8.56 | 8.56 | 13.49 | 17.12 |

| 125 | 5 | 141.3 | 5.56 | 2.77 | 3.40 | – | – | 6.55 | 6.55 | 9.53 | 9.53 | 15.88 | 19.05 |

| 150 | 6 | 168.3 | 6.62 | 2.77 | 3.40 | – | – | 7.11 | 7.11 | 10.97 | 10.97 | 18.26 | 21.96 |

| 200 | 8 | 219.1 | 8.62 | 2.77 | 3.76 | 6.35 | 7.04 | 8.18 | 8.18 | 12.70 | 12.70 | 23.01 | 22.23 |

| 250 | 10 | 273.0 | 10.75 | 3.40 | 4.19 | 6.35 | 7.80 | 9.27 | 9.27 | 15.09 | 12.70 | 28.58 | 25.40 |

| 300 | 12 | 323.8 | 12.75 | 3.96 | 4.57 | 6.35 | 8.38 | 10.13 | 9.53 | 17.48 | 12.70 | 33.32 | 25.40 |

| 350 | 14 | 355.6 | 14 | 3.96 | 4.78 | 7.92 | 9.53 | 11.13 | 9.53 | 19.05 | 12.70 | 35.71 | – |

| 400 | 16 | 406.4 | 16 | 4.19 | 4.78 | 7.92 | 9.53 | 12.70 | 9.53 | 21.44 | 12.70 | 40.49 | – |

| 450 | 18 | 457 | 18 | 4.19 | 4.78 | 7.92 | 11.13 | 14.27 | 9.53 | 23.83 | 12.70 | 45.24 | – |

| 500 | 10 | 508 | 20 | 4.78 | 5.54 | 9.53 | 12.70 | 15.09 | 9.53 | 26.19 | 12.70 | 50.01 | – |

| 550 | 22 | 559 | 22 | 4.78 | 5.54 | 9.53 | 12.70 | – | 9.53 | 28.58 | 12.70 | 53.98 | – |

| 600 | 24 | 610 | 24 | 5.54 | 6.35 | 9.53 | 14.27 | 17.48 | 9.53 | 30.96 | 12.70 | 59.54 | – |

| 650 | *26 | 660 | 26 | – | – | – | – | – | 9.53 | – | 12.70 | – | – |

| 700 | *28 | 711 | 28 | – | – | – | – | – | 9.53 | – | 12.70 | – | – |

| 750 | *30 | 762 | 30 | – | – | – | – | – | 9.53 | – | 12.70 | – | – |

| 800 | *32 | 813 | 32 | – | – | – | – | – | 9.53 | – | 12.70 | – | – |

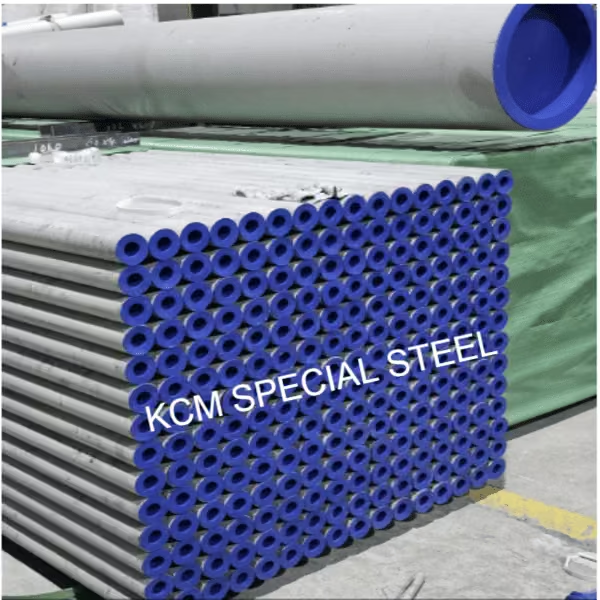

SS321 TP321 AISI321 321 Stainless Steel Pipe Supplier & Manufacturer in CHINA, contact us for more details and get high quality stainless steel 321 pipe Seamless & Welded

FAQ About 321 Stainless Steel Pipe

Product Information

Q1: What is 321 Stainless Steel Pipe made of?

A1: 321 stainless steel pipe is primarily composed of chromium (17-19%), nickel (9-12%), and titanium (≥5×C content), designed to enhance high-temperature stability and intergranular corrosion resistance.

Q2: What are the international standards for 321 Stainless Steel Pipe?

A2: 321 stainless steel pipe is standardized internationally as S32100 (ASTM), SUS321 (JIS), or TP321 (ASME).

Q3: Where to look for the suppliers and manufacturers of 321 Stainless Steel Pipe In CHINA?

A3: The suppliers and manufacturers of 321 stainless steel pipe featured on the website are KCM SPECIAL STEEL.

Specifications & Applications

Q4: What are the available specifications for 321 Stainless Steel Pipe?

A4: 321 stainless steel pipe is available in various diameters (OD: 6-2000MM) and thicknesses (0.5-60MM).

Q5: What are the primary applications of 321 Stainless Steel Pipe?

A5: 321 stainless steel pipe is widely used in industries such as petroleum & natural gas, chemical processing, food & pharmaceutical industries, automotive, medical & construction, and nuclear & power generation due to its corrosion resistance, high-temperature stability, and mechanical durability.

Properties & Advantages

Q6: What are the advantages of using 321 Stainless Steel Pipe?

A6: The titanium-stabilized alloy in 321 stainless steel pipe minimizes carbide precipitation during welding or prolonged high-temperature exposure, enhancing its durability and making it suitable for safety-critical applications. It also exhibits excellent resistance to thermal stress (up to 816°C).

Q7: What is the density of 321 Stainless Steel Pipe?

A7: The density of 321 stainless steel pipe is typically around 7.93 g/cm³, comparable to other austenitic stainless steels.

Summary of 321 Stainless Steel Pipe

321 stainless steel pipe, manufactured by KCM SPECIAL STEEL, is a versatile material widely used in multiple industries due to its corrosion resistance, high-temperature stability, and mechanical durability. It meets international standards such as ASTM, JIS, and ASME and is available in various specifications to cater to different application requirements. Its primary applications include industries like petroleum & natural gas, chemical processing, food & pharmaceutical, automotive, medical & construction, and nuclear & power generation. The titanium-stabilized alloy in 321 stainless steel pipe minimizes carbide precipitation, enhancing its durability and making it ideal for safety-critical applications. With its excellent properties and wide range of applications, 321 stainless steel pipe continues to be a valuable material in various sectors

SS321 TP321 AISI321 321 Stainless Steel Pipe Supplier & Manufacturer in CHINA, contact us for more details and get high quality stainless steel 321 pipe Seamless & Welde

.

Customer Case Studies & Feedback for 321 Stainless Steel Pipe

Case Study 1: Oil & Gas Industry

Client: Global Energy Solutions Co. (USA)

Challenge: The client required high-temperature-resistant piping for offshore drilling rigs exposed to corrosive seawater and extreme thermal cycling (up to 650°C). Traditional stainless steel pipes failed due to carbide precipitation during welding.

Solution: KCM SPECIAL STEEL supplied TP321 stainless steel pipes with titanium stabilization to minimize carbide formation. Customized dimensions (OD: 300MM, thickness: 15MM) were provided for seamless integration.

Results:

- Reduced maintenance costs by 40% over 2 years.

- Zero weld-related failures reported post-installation.

- Enhanced operational safety in corrosive environments.

Client Feedback:

“The TP321 pipes from KCMSS exceeded our expectations. Their technical team provided excellent support, and the material’s performance in high-temperature zones has been flawless. We’ll continue partnering with them for future projects.”

Product Used: TP321 Stainless Steel Pipe (ASME Standard).

Case Study 2: Pharmaceutical Manufacturing

Client: BioPharm Innovations Ltd. (Germany)

Challenge: The client needed ultra-clean, corrosion-resistant piping for sterile drug production systems. Strict compliance with FDA and EU GMP standards was mandatory.

Solution: KCMSS delivered stainless steel 321 pipes with electropolished interiors and certified traceability. Pipes were manufactured in sizes (OD: 73MM, thickness: 3.05MM) to minimize fluid retention.

Results:

- Achieved 100% compliance with hygiene and safety audits.

- Reduced downtime by 25% due to corrosion-free performance.

- Extended lifecycle of production equipment.

Client Feedback:

“KCMSS’s 321 stainless steel pipes are unmatched in quality. Their documentation and adherence to pharmaceutical-grade standards made the approval process seamless. Highly recommended for critical applications.”

Product Used: Stainless Steel 321 Pipe (ASTM A312).

Case Study 3: Nuclear Power Plant

Client: National Nuclear Energy Corp. (South Korea)

Challenge: The client sought radiation-resistant piping for coolant systems in reactors, requiring stability under prolonged thermal stress (500–800°C).

Solution: KCMSS supplied SS321 pipes with enhanced titanium content (≥5×C) and rigorous non-destructive testing (NDT) to ensure integrity.

Results:

- Sustained zero leaks over 5 years of operation.

- Met ASME Section III nuclear safety requirements.

- Reduced replacement frequency by 60%.

Client Feedback:

“KCMSS’s expertise in nuclear-grade materials is exceptional. The SS321 pipes have performed reliably under extreme conditions, and their technical support team was instrumental in addressing our unique needs.”

Product Used: SS321 Stainless Steel Pipe (ASME Section III).

Case Study 4: Automotive Exhaust Systems

Client: GreenDrive Automotive (Japan)

Challenge: The client needed lightweight, heat-resistant exhaust components to meet emissions regulations and reduce vehicle weight.

Solution: KCMSS provided 321 stainless steel pipes with thin-wall designs (thickness: 1.5MM) and superior oxidation resistance for high-temperature exhaust gases.

Results:

- Achieved 15% weight reduction in exhaust systems.

- Passed stringent emissions testing with no degradation.

- Lowered production costs by optimizing material usage.

Client Feedback:

“KCM’s 321 stainless steel pipes were pivotal in meeting our sustainability goals. Their product’s durability and lightweight properties gave us a competitive edge in the market.”

Product Used: 321 Stainless Steel Pipe (JIS G3463).

Key Takeaways from Customer Feedback

- Reliability: Clients consistently praised KCMSS’s 321 stainless steel pipes for durability in extreme environments.

- Compliance: Products met international standards (ASME, ASTM, JIS) and industry-specific certifications.

- Technical Support: KCMSS’s engineering team was highlighted for responsive, solution-oriented collaboration.

- Cost Efficiency: Reduced maintenance and replacement costs were a recurring benefit across industries.