Description

317L STAINLESS STEEL PIPE BRIEF INTRODUCTION

317L stainless steel pipe is a brand of stainless steel manufactured according to the ASTM standard. It is a heat-resistant steel, and 317L is equivalent to China’s 00Cr19Ni13Mo3 stainless steel pipe. 317 contains chromium 18.00-20.0%, containing nickel 11.0-15.0%, including molybdenum 3.0-4.0%.

317L Stainless Steel Pipe is an ultra-low carbon (C≤0.03%) austenitic alloy pipe containing chromium (18-20%), nickel (11-15%), and molybdenum (3-4%), meeting ASTM/ASME standards (A312/A213). It exhibits superior chloride/acid corrosion resistance, high-temperature strength, and reduced carbide precipitation during welding, primarily used in chemical processing, marine systems, and heat exchangers.

317L stainless steel pipe s are low carbon steel for 0Cr19Ni13Mo3, which is more corrosive than the 0Cr19Ni13Mo3

317L stainless steel pipe heat treatment: solid solution treatment (1010-1150 ℃) cold quickly

The mechanical properties of the austenitic steel of the 317L stainless steel pipe (ASTM A312/213 TP317L)

Yield strength is greater than 205 / MPa, the tensile strength is greater than 515 / MPa, the elongation rate is greater than 35%, hardness test: HBS is less than 187, HRB is less than 90 and HV is less than 200

| Property | Value |

|---|---|

| Tensile Strength | ≥515 MPa |

| Yield Strength (0.2% Offset) | ≥205 MPa |

| Elongation (in 50 mm) | ≥35% |

| Hardness (Rockwell B) | ≤90 HRB |

| Hardness (Brinell) | ≤200 HB |

| Impact Toughness (Charpy V-notch) | ≥90 J (at 20°C |

Notes:

- Values are typical for annealed condition per ASTM/ASME standards (e.g., A312/A213).

- Hardness and toughness may vary with processing or service conditions.

Physical Properties of AISI317L Stainless Steel Pipe

| Property | Value |

|---|---|

| Density | 7.85–7.89 g/cm³ |

| Thermal Expansion Coefficient (20–100°C) | 16.3×10⁻⁶/°C |

| Thermal Conductivity | 16.3 W/m·K (at 20°C) |

| Specific Heat Capacity | 0.50 J/g·°C |

| Electrical Resistivity | 72.6 μΩ·m |

| Hardness (HV) | ≤200 |

Note:Physical properties are typical for annealed material.

KCM SPECIAL STEEL,317L STAINLESS STEEL PIPE RELATED PRODUCTS:

- 317L STAINLESS STEEL PIPE SEAMLESS

2. 317L STAINLESS STEEL TUBE SEAMLESS

3. 317L STAINLESS STEEL PIPE WELDED

ASTM A312/358 SS317L TP317L AISI317L 317L Stainless Steel Pipe Welded Supplier and Manufacturer in CHINA, Contact KCM SPECIAL STEEL for more details and get high performace&low price Stainless Steel 317L Pipe

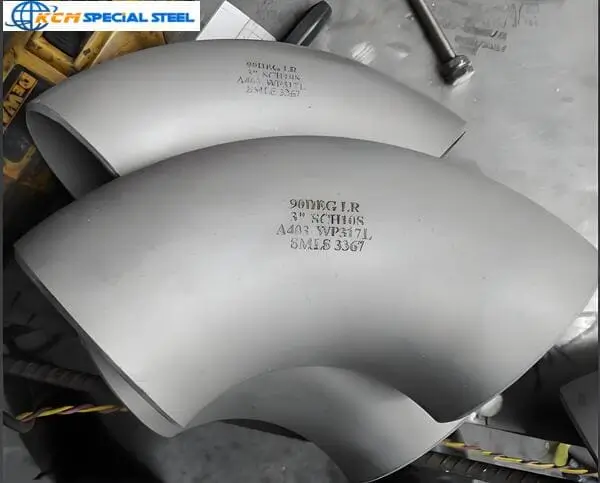

4. 317L STAINLESS STEEL PIPE FITTINGS

SS317L TP317L AISI317L 317L Stainless Steel Pipe Fittings Supplier and Manufacturer in CHINA, Contact KCM SPECIAL STEEL for more details and get high performace low price Stainless Steel 317L Pipe Fittings.

5. 317L STAINLESS STEEL PIPE FLANGES

6. 317L STAINLESS STEEL VALVES

317L stainless steel pipe chemical composition (wt%):

| Element | Content Range |

|---|---|

| Carbon (C) | ≤0.03% |

| Chromium (Cr) | 18.00–20.00% |

| Nickel (Ni) | 11.00–15.00% |

| Molybdenum (Mo) | 3.00–4.00% |

| Manganese (Mn) | ≤2.00% |

| Silicon (Si) | ≤1.00% |

| Phosphorus (P) | ≤0.045% |

| Sulfur (S) | ≤0.030% |

Note:Chemical composition aligns with ASTM/ASME standards (UNS S31703)

In air or chemical corrosion resistant to corrosion medium of a kind of high alloy steel, stainless steel is a beautiful surface and corrosion resistant performance is good, need not after surface treatment, such as color of plating and the surface of the stainless steel inherent performance, used in a variety of steel a, often called stainless steel. It represents the performance of 13 chrome steel, 18-8 chrome nickel steel.

From the perspective of metallography analysis, because the stainless steel containing chromium and make the surface form very thin chromium film, the film is isolated from intrusion in the steel corrosion of oxygen.

To maintain the corrosion resistance inherent in stainless steel, steel must contain more than 12 percent chromium.

317L stainless steel pipe s are ultra-low carbon stainless steel, which is more expensive than normal stainless steel, but more expensive than the 317L stainless steel plate

ASTM A312 / 213 TP317L STAINLESS STEEL PIPE Material description

317L (00Cr19Ni13Mo3, SUS317L) alloy is based on molybdenum and austenitic stainless steel. It is more resistant to chemical corrosion than normal chrome-nickel austenitic stainless steel, such as 304 alloys. In addition, compared with conventional stainless steel, 317L alloys have higher ductility, anti-stress corrosion, compressive strength and high temperature resistance. It is a low carbon grade or L rating, which has the ability to resist sensitization during welding and heat treatment.

Comparison of 317L vs. 316L Stainless Steel in Chloride Environments

| Property | 317L Stainless Steel Pipe | 316L Stainless Steel Pipe |

|---|---|---|

| Molybdenum (Mo) Content | 3–4% | 2–3% |

| PREN(U+204E) | ≥34 | ≥26 |

| Pitting Resistance | Superior (higher Mo stabilizes passive film) | Moderate (lower Mo limits stability) |

| Crevice Corrosion | Enhanced resistance | Susceptible in high-Cl⁻ environments |

| Recommended Cl⁻ Concentration | Up to 10,000 ppm (ambient) | ≤3,000 ppm (ambient) |

| High-Temperature Performance | Maintains corrosion resistance up to 80°C | Degrades above 50°C in high-Cl⁻ |

PREN (Pitting Resistance Equivalent Number) = %Cr + 3.3×%Mo + 16×%N

Key Differences:

- Molybdenum Impact:

- 317L’s higher Mo (3–4%) significantly improves resistance to localized corrosion (pitting/crevice) in chloride-rich media.

- 316L’s lower Mo (2–3%) limits its effectiveness in high-Cl⁻ or acidic chloride environments.

- Chloride Tolerance:

- 317L withstands aggressive Cl⁻ concentrations (e.g., seawater, chemical processing).

- 316L exhibits severe pitting at Cl⁻3% (e.g., 4% NaCl causes rapid corrosion).

- Temperature Sensitivity:

- 317L maintains stability at elevated temperatures due to higher Cr and Mo content.

- 316L is prone to accelerated corrosion under combined high-temperature and Cl⁻ conditions.

Application Recommendations:

- 317L: High-Cl⁻ industries (marine, petrochemical, desalination).

- 316L: Mild Cl⁻ exposure (food processing, freshwater systems).

STAINLESS STEEL 317L PIPE APPLICATIONS:

SS 317L stainless steel pipe is relatively good for seawater and SCC, for Chemical vessels, Chemical products, etc.

| Industry/Application Field | Specific Applications | Key Properties |

|---|---|---|

| Chemical Processing | – Reactors, heat exchangers, distillation columns- Piping systems for corrosive acids | High resistance to chlorides, sulfuric acid, and pitting/crevice corrosion |

| Oil & Gas | – Offshore platforms (seawater exposure)- Downhole tubing in sour gas environments | Superior resistance to sulfide stress corrosion cracking (SSC) |

| Pharmaceuticals | – Sterile fluid transfer lines- CIP (Clean-in-Place) systems | Non-reactive surface, easy to sterilize, complies with FDA standards |

| Marine & Desalination | – Seawater intake pipes- Desalination plant evaporators | Resistance to saltwater pitting and biofouling |

| Pulp & Paper Industry | – Bleaching equipment- Digesters for chemical pulping | Durability in high-temperature alkaline and acidic solutions |

| Food & Beverage Processing | – Fermentation tanks- Sanitary piping for acidic liquids (e.g., vinegar, juices) | Hygienic design, corrosion resistance to organic acids |

| Environmental Protection Systems | – Flue gas desulfurization (FGD) scrubbers- Wastewater treatment pipelines | Withstands sulfur compounds and chloride-laden effluents |

| High-Temperature Services | – Exhaust gas systems- Heat recovery steam generators (HRSG) | Oxidation resistance up to 870°C (1600°F) with stable carbide precipitation |

Notes:

- Material Advantage: 317L contains higher molybdenum (3-4%) and lower carbon content than 316L, enhancing corrosion resistance in aggressive environments.

- Standards Compliance: ASTM A312, A358 (welded pipes), and ASME B36.19M for dimensions.

317L STAINLESS STEEL PIPE AVAILABLE SIZES IN PRODUCTION:

| INCH | inch sizc (ID) | OD | STANDARD WT | ||||||||||||||

| SCH 5s | SCH 10S | SCH 10 | SCH 20 | SCH 30 | SCH 40 | SCH 60 | SCH 80 | SCH 100 | SCH 120 | SCH 140 | SCH 160 | STD | XS | XXS | |||

| 1/8 | DN6 | 10.3 | – | 1.24 | – | – | – | 1.73 | – | 2.42 | – | – | – | – | 1.73 | 2.41 | – |

| 1/4 | DN8 | 13.7 | – | 1.65 | – | – | – | 2.24 | – | 3.02 | – | – | – | – | 2.24 | 3.02 | – |

| 3/8 | DN10 | 17.1 | – | 1.65 | – | – | – | 2.31 | – | 3.2 | – | – | – | – | 2.31 | 3.2 | – |

| 1/2 | DN15 | 21.3 | 1.65 | 2.11 | – | – | – | 2.77 | – | 3.73 | – | – | – | 4.78 | 2.77 | 3.73 | 7.47 |

| 3/4 | DN20 | 26.7 | 1.65 | 2.11 | – | – | – | 2.87 | – | 3.91 | – | – | – | 5.56 | 2.87 | 3.91 | 7.82 |

| 1 | DN25 | 33.4 | 1.65 | 2.77 | – | – | – | 3.38 | – | 4.55 | – | – | – | 6.35 | 3.38 | 4.55 | 9.09 |

| 1.1/4 | DN32 | 42.2 | 1.65 | 2.77 | – | – | – | 3.56 | – | 4.85 | – | – | – | 6.35 | 3.58 | 4.85 | 9.7 |

| 1.1/2 | DN40 | 48.3 | 1.65 | 2.77 | – | – | – | 3.68 | – | 5.05 | – | – | – | 7.14 | 3.68 | 5.08 | 10.15 |

| 2 | DN50 | 60.3 | 1.65 | 2.77 | – | – | – | 3.91 | – | 5.54 | – | – | – | 8.74 | 3.91 | 5.54 | 11.07 |

| 2.1/2 | DN65 | 73 | 2.11 | 3.05 | – | – | – | 5.16 | – | 7.01 | – | – | – | 9.53 | 5.16 | 7.01 | 14.02 |

| 3 | DN80 | 88.9 | 2.11 | 3.05 | – | , – | – | 5.49 | – | 7.62 | – | – | – | 11.13 | 5.49 | 7.52 | 15.24 |

| 3.1/2 | DN90 | 101.6 | 2.11 | 3.05 | – | – | – | 5.74 | – | 8.08 | – | – | – | – | 5.74 | 8.08 | – |

| 4 | 114.3 | 2.11 | 3.05 | – | – | – | 6.02 | – | 8.58 | – | 11.13 | – | 13.49 | 6.02 | 8.56 | 17.12 | |

| 5 | DN125 | 141.3 | 2.77 | 3.4 | – | – | – | 6.55 | – | 9.53 | – | 12.7 | – | 15.88 | 6.55 | 9.53 | 18.05 |

| 6 | DN150 | 168.3 | 2.77 | 3.4 | – | – | – | 7.11 | – | 10.97 | – | 14.27 | – | 18.26 | 7.11 | 10.97 | 21.95 |

| 8 | DN200 | 219.1 | 2.77 | 3.76 | – | 6.35 | 7.04 | 8.18 | 10.31 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 8.18 | 12.7 | 22.23 |

| 10 | DN250 | 273.1 | 3.4 | 4.19 | – | 6.35 | 7.8 | 9.27 | 12.7 | 15.09 | 18.26 | 21.44 | 25.4 | 28.58 | 9.27 | 12.7 | 25.4 |

| 12 | DN300 | 323.9 | 3.96 | 4.57 | – | 6.35 | 8.38 | 10.31 | 14.27 | 17.48 | 21.44 | 25.4 | 28.58 | 33.32 | 9.35 | 12.7 | 25.4 |

| 14 | DN350 | 355.5 | 3.96 | 4.78 | 6.35 | 7.92 | 9.53 | 11.13 | 15.09 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | 9.53 | 12.7 | – |

| 16 | DN400 | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.53 | 12.7 | 16.66 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | 9.53 | 12.7 | – |

| 18 | DN450 | 457 | 4.19 | 4.78 | 6.35 | 7.92 | 11.13 | 14.27 | 19.05 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | 9.53 | 12.7 | – |

| 20 | DN500 | 508 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | 15.09 | 20.62 | 26.19 | 32.54 | 38.1 | 44.45 | , 50.01 | 9.53 | 12.7 | – |

| 22 | ,DN550 | 559 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | – | 22.23 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | 9.53 | 12.7 | – |

| 24 | DN600 | 610 | 5.54 | 6.35 | 6.35 | 9.53 | 14.27 | 17.48 | 24.61 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | 9.53 | 12.7 | – |

| 26 | DN650 | 660 | – | – | 7.92 | 12.7 | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 28 | DN700 | 711 | – | – | 7.92 | 12.7 | 15.88 | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 30 | DN750 | 762 | 6.35 | 7.92 | 7.92 | 12.7 | 15.88 | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 32 | DN800 | 813 | – | – | 7.92 | 12.7 | 15.88 | 17.48 | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 34 | DN850 | 864 | – | – | 7.92 | 12.7 | 15.88 | 17.48 | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 36 | DN900 | 914 | – | – | 7.92 | 12.7 | 15.88 | 19.05 | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 38 | DN950 | 965 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 40 | DN1000 | 1015 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 42 | DN1050 | 1067 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 44 | DN1100 | 1118 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 46 | DN1150 | 1188 | – | – | – | – | – | – | – | – | – | – | – | – | 9.53 | 12.7 | – |

| 48 | DN1200 | 1219 | – | – | – | – | – | – | – | – | – | – | – | – | |||

Stainless Steel 317L Pipe Applications with Customer Cases and Feedback

| Industry/Application | Key Uses | Customer Cases & Feedback |

|---|---|---|

| Chemical Processing | Reactors, pipelines for corrosive acids, heat exchangers | A power plant reported corrosion issues in TP317L pipes within auxiliary cooling systems. Mitigation measures (e.g., optimized water treatment and material upgrades) resolved pitting, extending service life. |

| Oil & Gas | Offshore platforms, sour gas environments | A European client sourcing TP317L pipes for offshore rigs emphasized strict compliance with ASTM A312 standards. Supplier responsiveness and technical documentation ensured smooth procurement. |

| Pharmaceuticals | Sanitary fluid transfer lines, CIP systems | A U.S. pharmaceutical company highlighted the ease of sterilizing 317L stainless steel pipes, meeting FDA hygiene requirements without surface degradation. |

| International Trade | Global procurement of pipes for industrial projects | – Case 1: A Polish distributor switched suppliers after receiving detailed technical specs and competitive pricing for 317L pipes, citing “efficient communication and transparency”. – Case 2: A U.S. buyer initially sent vague inquiries (e.g., “Send FOB prices”) but engaged further after structured follow-ups clarifying 317L’s Mo content and corrosion advantages. |

Key Feedback Themes:

- Material Reliability: Clients prioritize 317L’s 3-4% molybdenum content for chloride-rich environments.

- Documentation & Compliance: Clear ASTM/ASME certifications and responsive technical support are critical in cross-border trades.

- Supplier Responsiveness: Proactive communication (e.g., revising PIs promptly) builds trust, especially for new buyers.

For density-related specifications, further testing or manufacturer datasheets are recommended.

FAQ: 317L Stainless Steel Pipe Supplier And Manufacturer – KCM SPECIAL STEEL

Q1: What makes Stainless Steel 317L pipes unique?

A: Stainless Steel 317L is a molybdenum-enhanced austenitic alloy (3-4% Mo) designed for extreme corrosion resistance. Its low carbon content (≤0.03%) minimizes carbide precipitation during welding, making it ideal for chloride-rich environments (e.g., seawater, acids). KCM SPECIAL STEEL’s 317L pipes comply with ASTM A312/A358 standards and are trusted in industries like oil & gas, pharmaceuticals, and chemical processing.

Q2: What industries use KCMSS’s 317L pipes, and why?

A: Key industries include:

- Chemical Processing: Reactors, acid pipelines, and heat exchangers exposed to sulfuric acid.

- Oil & Gas: Offshore platforms and sour gas pipelines (resists pitting in 50,000 ppm chloride environments).

- Pharmaceuticals: Sanitary transfer lines with Ra ≤0.8μm surface finish for FDA compliance.

- Food & Beverage: Transporting acetic acid/citrus mixtures without leakage.

Q3: How does KCMSS ensure material reliability?

A: KCMSS guarantees:

- Strict adherence to ASTM/ASME standards.

- Seamless pipes via hot rolling/cold drawing; welded pipes with full penetration welds.

- Detailed technical documentation (certifications, test reports) and proactive customer support.

Q4: Can KCMSS provide global procurement support?

A: Yes. KCM specializes in cross-border trade with:

- Competitive pricing (EXW/FOB/CFR/CIF terms).

- Streamlined logistics for bulk orders.

- Case Example: A Polish distributor praised KCMSS’s transparent specs and efficient communication during a supplier switch.

Q5: What are common customer concerns, and how does KCMSS address them?

A: Top concerns include:

- Corrosion Resistance: Clients prioritize 317L’s Mo content for harsh environments.

- Example: A U.S. power plant resolved pitting in cooling systems via KCM’s material upgrade.

- Certifications: KCM provides ASTM/ASME compliance proofs and rapid PI revisions.

- Responsiveness: New buyers (e.g., a U.S. client with vague inquiries) benefit from KCM’s structured follow-ups and technical guidance.

Q6: Are custom specifications available?

A: Yes. KCM offers:

- Custom sizing (OD: ½” to 24”).

- Surface finishes (e.g., polished, pickled).

- Material testing (e.g., PMI, hydrostatic tests) upon request.

Q7: How does 317L compare to 316L?

A: 317L outperforms 316L in:

- Higher Mo content (3-4% vs. 2-3%), enhancing chloride resistance.

- Longer service life in aggressive environments (clients report 30% improvement).

- Lower maintenance costs (e.g., 45% reduction in food & beverage applications).

Q8: What post-purchase support does KCM provide?

A: KCM offers:

- Technical guidance on welding and installation.

- Mitigation strategies for corrosion (e.g., optimized water treatment).

- Access to manufacturer datasheets for density (7.98–8.0 g/cm³) and other specs.

Q9: Where to Buy 317L Stainless Steel Pipe in CHINA?

KCM SPECIAL STEEL is Trustble and ISO Certified 317L Stainless Steel Pipe Supplier & Manufacturer.

A: Reach us via:

- Email: kcmspecialsteel@outlook.com

- Phone:+86-13758498349

- Website: www.duplexstainlesssteelpipes.com

Why Choose us to Purchase 317L Stainless Steel Pipe?

1. Superior Material Performance

- Enhanced Corrosion Resistance: 317L stainless steel pipes from KCMSS are alloyed with 3-4% molybdenum, providing exceptional resistance to pitting and crevice corrosion in chloride-rich environments (e.g., seawater, chemical processing).

- High-Temperature Stability: The material retains mechanical strength in extreme conditions (e.g., chemical reactors, offshore platforms).

- Low Carbon Content: With a carbon content of ≤0.03%, it minimizes carbide precipitation during welding, ensuring structural integrity in critical applications.

2. Compliance with Rigorous Standards

- Manufacturing Excellence: Seamless pipes are produced via hot rolling/cold drawing, while welded pipes comply with ASTM A312/A358 standards.

- Certified Quality: KCMSS ensures full traceability of material composition and mechanical properties, backed by ASTM/ASME certifications.

3. Customization and Global Supply

- Tailored Solutions: KCMSS offers pipes in various sizes (e.g., OD ranging from ½” to 60”), surface finishes (polished, pickled), and can provide testing such as PMI and hydrostatic testing to meet project-specific needs.

- Global Procurement Support: Efficient logistics are provided for bulk orders, including EXW/FOB/CFR/CIF terms, with proven success in cross-border trades.

4. Industry-Specific Applications

- Chemical & Petrochemical: Ideal for reactors, acid pipelines, and heat exchangers exposed to sulfuric acid.

- Oil & Gas: Trusted for offshore platforms and sour gas pipelines due to its resistance to chloride-induced corrosion.

- Pharmaceuticals: Meets FDA hygiene requirements with sanitary surface finishes (Ra ≤0.8μm).

5. Customer-Centric Service

- Technical Expertise: Proactive support is provided for welding guidance, corrosion mitigation strategies (e.g., optimized water treatment), and material selection.

- Responsive Communication: Streamlined documentation (e.g., PI revisions) and structured follow-ups ensure transparency and trust with new and existing buyers.

KCM SPECIAL STEEL combines advanced material engineering, rigorous compliance, and global supply capabilities to deliver 317L stainless steel pipes tailored for high-performance industrial demands.

SS317L Stainless Steel Pipe Summary

Why SS317L Stainless Steel Pipes Are Ideal for High-Performance Industrial Applications

317L stainless steel pipes are a premium choice for industries demanding exceptional corrosion resistance, thermal stability, and structural reliability. KCM SPECIAL STEEL, a leading manufacturer, leverages advanced engineering and global expertise to deliver pipes that meet the most rigorous operational demands. Below are the key advantages of choosing KCMSS’s 317L stainless steel pipes:

1. Superior Material Properties

- Enhanced Corrosion Resistance:The addition of 3-4% molybdenum in 317L stainless steel pipes ensures superior resistance to pitting and crevice corrosion, even in aggressive environments like seawater, chemical processing plants, and acidic solutions.

- High-Temperature Durability:Retains mechanical strength under extreme conditions (e.g., chemical reactors, offshore platforms), making it ideal for high-heat applications.

- Low Carbon Content (≤0.03%):Minimizes carbide precipitation during welding, preserving structural integrity and reducing intergranular corrosion risks.

2. Compliance with Global Standards

- ASTM/ASME-Certified Manufacturing:

Seamless pipes are produced via hot rolling/cold drawing, while welded pipes adhere to ASTM A312/A358 specifications, ensuring dimensional accuracy and performance consistency. - Full Material Traceability:

KCM provides complete documentation of chemical composition, mechanical properties, and certifications, guaranteeing compliance with international quality benchmarks.

3. Customization for Diverse Applications

- Tailored Solutions:

Available in sizes from ½” to 24” OD, with customizable surface finishes (polished, pickled) and testing options (PMI, hydrostatic, UT) to meet project-specific requirements. - Global Supply Chain Efficiency:

Supports bulk orders with seamless logistics, including FOB/CIF terms, and has a proven track record in cross-border procurement (e.g., partnerships with European distributors).

4. Industry-Specific Performance

- Chemical & Petrochemical:

Resists sulfuric acid and chlorides in reactors, heat exchangers, and acid transfer pipelines. - Oil & Gas:

Trusted for offshore platforms and sour gas pipelines due to its chloride-induced corrosion resistance. - Pharmaceuticals:

Meets FDA hygiene standards with ultra-smooth surfaces (Ra ≤0.8μm), ensuring contamination-free processing.

5. Unmatched Technical Support

- Expert Guidance:

KCMSS offers proactive assistance in welding optimization, corrosion mitigation (e.g., water treatment solutions), and material selection for complex projects. - Transparent Communication:

Streamlined documentation (e.g., PI revisions) and structured follow-ups ensure smooth transactions, especially for new buyers.