Description

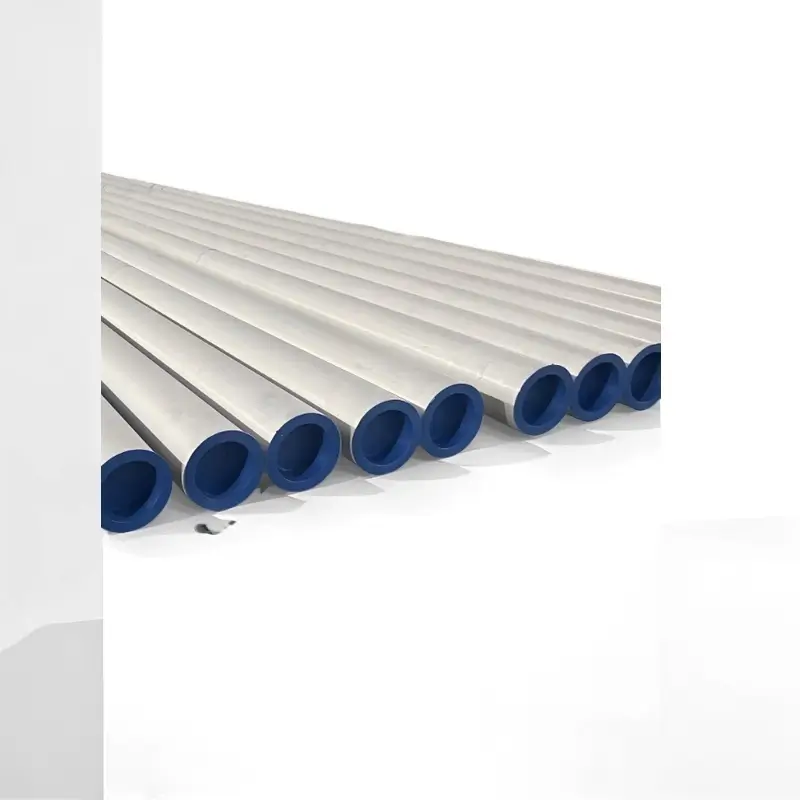

316L Stainless Steel Pipe Brief Introdcution

316L stainless steel pipe is a hollow long round steel, mainly is widely used in petroleum, chemical, medical, food, light industry, machinery, instrument and other industrial pipeline and mechanical structure parts, etc.

In addition, in bending and torsion strength, the weight is lighter, therefore it is also widely used to make mechanical parts and engineering structures. Futher It is also used to produce all kinds of conventional weapons, guns and shells.

What is Stainless Steel 316L Pipe?

316L Stainless Steel Pipe is austenitic stainless steel pipe with low carbon (C≤0.03%) and molybdenum (Mo:2–3%), offering exceptional chloride corrosion resistance. Complies with ASTM A312/ASME standards, widely used in marine, chemical, and medical industries

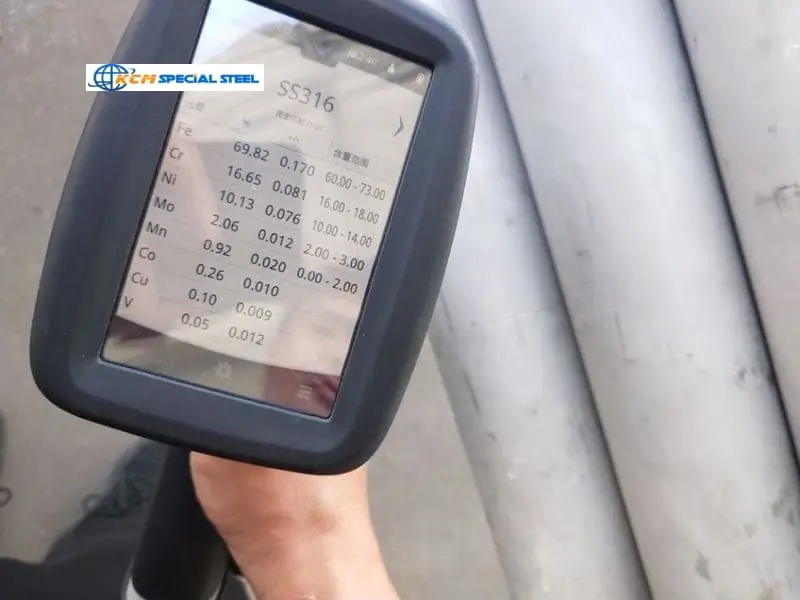

SS316L TP316L AISI316L 316L Stainless Steel Pipe mainly contains chemicals of 16.00% – 18.00% Cr, 10.00% – 14.00% Ni, 2.00% – 3.00% Mo, ≤0.030% C, which is also a derivative steel of 18-8 type austenitic stainless steel with Excellent corrosion resistance.

The American standard stipulates that the Ni content of 316L is 10-14%, and the Japanese standard stipulates that the Ni content of 316L is 12-15%.

According to the minimum standard, there is a 2% difference in Ni content between the American standard and the Japanese standard, which is still quite huge in terms of price. Therefore, customers still need to see clearly when purchasing 316L products, whether the product is based on ASTM/JIS/DIN /EN/GOST standards.

The Mo content of 316L Stainless Steel Pipe makes the steel have excellent resistance to pitting corrosion and can be safely used in environments containing halogen ions such as Cl-.

Because 316L is mainly used for its chemical properties, therefore steel mills have slightly lower requirements for surface inspection of 316L (relative to 304). Customers with higher requirements on the surface should strengthen the surface inspection.

Chemical Composition of 316L Stainless Steel Pipe

| Element | Content Range (%) |

|---|---|

| Carbon (C) | ≤0.030 |

| Silicon (Si) | ≤1.00 |

| Manganese (Mn) | ≤2.00 |

| Phosphorus (P) | ≤0.045 |

| Sulfur (S) | ≤0.030 |

| Chromium (Cr) | 16.0–18.0 |

| Nickel (Ni) | 10.0–14.0 |

| Molybdenum (Mo) | 2.0–3.0 |

| Nitrogen (N) | ≤0.10 |

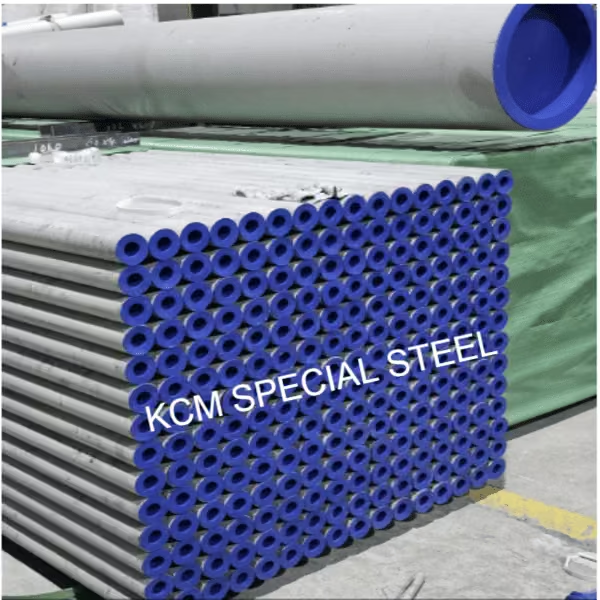

Stainless Steel 316L Pipe PMI Test Picture

SS316L/TP316L/AISI316L/1.4404/316L Stainless Steel Pipe PMI Test For Clients’ Reference,KCM SPECIAL STEEL Is Trustble Stainless Steel 316L Pipe Manufacturer And Supplier

Stainless Steel 316L Pipe Physical and Mechanical Properties

| Property | Value Range |

|---|---|

| Density | ~8.0 g/cm³ |

| Yield Strength (YS) | ≥205 MPa |

| Tensile Strength (TS) | ≥520 MPa |

| Elongation (EL) | ≥40% |

| Hardness (HV) | ~200 |

Key Features:

- Superior corrosion resistance in chloride-rich environments (e.g., marine, chemical industries) due to Mo and Ti additions .

- Enhanced high-temperature stability and creep resistance

SS316L/TP316L/AISI316L/1.4404/316L Stainless Steel Pipe Creep Rupture Strength & Thermal Conductivity at Elevated Temperatures

1. Creep Rupture Strength

Creep rupture strength measures a material’s ability to withstand stress over time at high temperatures. Below are values for 316L, 304L, and duplex steels:

| Material | Temperature | Creep Rupture Strength (MPa) |

|---|---|---|

| 316L | 600°C | 80–100 (1000h) |

| 304L | 600°C | 60–80 (1000h) |

| Duplex Steel | 600°C | 120–150 (1000h) |

| 309S (Reference) | 800°C | 37.98 (1000h) |

Key Observations:

Duplex steels exhibit superior creep resistance compared to austenitic grades (e.g., 316L/304L) due to dual-phase microstructure and precipitation hardening8.

At 800°C, 309S (a high-Cr austenitic steel) shows significantly reduced strength, highlighting limitations of standard austenitic steels in extreme heat7.

2. Thermal Conductivity

Thermal conductivity determines heat transfer efficiency. Values vary with temperature:

| Material | Temperature | Thermal Conductivity (W/m·K) |

|---|---|---|

| 316L | 600°C | 19–21 |

| 304L | 600°C | 18–20 |

| Duplex Steel | 600°C | 14–16 |

| INCONEL 601 | 600°C | 14.5 |

Key Observations:

Austenitic steels (316L/304L) have higher thermal conductivity than duplex steels, making them preferable for heat exchangers4.

Duplex steels’ lower conductivity is offset by their strength and corrosion resistance in aggressive environments8.

Comparative Analysis

| Property | 316L | 304L | Duplex Steel |

|---|---|---|---|

| Creep Rupture Strength | Moderate (80–100 MPa) | Lower (60–80 MPa) | Highest (120–150 MPa) |

| Thermal Conductivity | Higher (19–21 W/m·K) | Moderate (18–20 W/m·K) | Lower (14–16 W/m·K) |

| Best Application | Heat exchangers, steam systems | Low-stress corrosive environments | High-pressure, high-temperature pipelines |

Guidance:

316L: Balanced corrosion resistance and heat transfer.

Duplex Steel: Superior strength for extreme conditions.

Summary

Performance Trade-offs:

Austenitic steels (316L/304L) suit moderate heat and corrosion scenarios.

Duplex steels dominate high-stress, high-temperature applications.

Material Selection:

Heat Transfer Priority: Choose 316L or 304L.

Strength Priority: Opt for duplex grades.

Various Standards Of 316L Stainless Steel pipe Introduction

ASTM A312 TP316L Stainless Steel Pipe

The ASTM A312 TP316L Stainless Steel Pipe is a low-carbon austenitic stainless steel material designed for high-temperature and corrosive environments, compliant with ASTM A312 standards. Its composition includes chromium (16–18%), nickel (10–14%), and molybdenum (2–3%), with carbon content ≤0.03%, minimizing carbide precipitation during welding.

This pipe exhibits excellent mechanical strength, including tensile strength ≥485 MPa and yield strength ≥170 MPa, suitable for high-pressure applications. Its density of approximately 8.0 g/cm³ ensures a balance between lightweight properties and corrosion resistance.

Widely used in chemical processing, pharmaceuticals, food production, and marine engineering, TP316L excels in chloride-rich environments like seawater desalination and chemical transport. Surface smoothness meets hygienic standards, ideal for sterile facilities.

Manufacturing involves cold rolling, welding, and heat treatment (e.g., solution annealing) to optimize microstructure. Strict quality controls—hydrostatic testing, ultrasonic inspection—guarantee leak-proof performance68. Customizable dimensions range from 6–1626 mm in outer diameter and 0.5–60 mm in wall thickness.

ASTM A213 TP316L Stainless Steel Pipe

The ASTM A213 TP316L stainless steel pipe is a low-carbon austenitic alloy designed for high-temperature and corrosive environments, widely used in boilers, heat exchangers, and superheaters. Its composition includes chromium (16–18%), nickel (10–14%), and molybdenum (2–3%), with carbon content ≤0.03% to minimize carbide precipitation during welding.

This material offers excellent mechanical properties, such as tensile strength ≥485 MPa and yield strength ≥170 MPa, ensuring durability under high-pressure conditions. With a density of approximately 8.0 g/cm³, it balances lightweight design and structural integrity.

TP316L excels in resisting chloride-induced corrosion, making it ideal for marine engineering, chemical processing, and desalination systems35. Its smooth surface and hygienic properties suit pharmaceutical and food industries.

Manufacturing involves cold rolling, welding, and solution annealing to enhance microstructure and stress resistance. Strict quality checks—hydrostatic testing, ultrasonic inspection—guarantee leak-proof performance46. Available in outer diameters of 6–824 mm and wall thicknesses of 0.5–65 mm, it supports customized industrial applications.

ASTM A269 TP316L Stainless Steel Tube

The ASTM A269 TP316L stainless steel tube is a low-carbon austenitic alloy designed for hygienic and high-corrosion applications, compliant with ASTM A269 standards. Its composition includes chromium (16–18%), nickel (10–14%), and molybdenum (2–3%), with ≤0.03% carbon to reduce carbide precipitation during welding.

This tube features a smooth bright annealed (BA) surface, ideal for pharmaceuticals, food processing, and biotechnology due to strict sanitary requirements12. It resists chloride-induced corrosion, making it suitable for marine environments and chemical transport.

Manufacturing involves seamless or welded processes, followed by solution annealing to optimize microstructure and stress resistance. Rigorous quality controls—hydrostatic testing, ultrasonic inspection—ensure leak-proof performance45. Customizable dimensions (OD: 6–824 mm; wall thickness: 0.5–65 mm) support diverse industrial needs.

ASTM A511 AISI316L Stainless Steel Tube

The ASTM A511 AISI316L stainless steel tube is a low-carbon austenitic alloy designed for mechanical applications requiring corrosion resistance and structural integrity, compliant with ASTM A511 standards. Its composition includes chromium (16–18%), nickel (10–14%), and molybdenum (2–3%), with carbon ≤0.03% to minimize carbide precipitation during welding.

This tube offers high strength, with tensile strength ≥485 MPa and yield strength ≥170 MPa, suitable for pressure systems and industrial equipment16. Its density of 8.0 g/cm³ ensures durability while maintaining lightweight properties.

AISI316L excels in resisting chloride-induced corrosion, making it ideal for marine engineering, chemical processing, and medical devices5. The smooth surface finish meets hygienic standards for food and pharmaceutical industries.

Manufacturing involves cold drawing or welding, followed by solution annealing to enhance microstructure and stress resistance. Rigorous quality controls ensure leak-proof performance and dimensional accuracy. Customizable dimensions (OD: 6–824 mm; wall thickness: 0.5–65 mm) adapt to diverse industrial needs.

ASTM A249 TP316L Stainless Steel Pipe

The ASTM A249 TP316L stainless steel pipe is a low-carbon austenitic alloy designed for high-temperature and corrosive environments, widely used in boilers, heat exchangers, and condensers. Its composition includes chromium (16–18%), nickel (10–14%), and molybdenum (2–3%), with carbon content ≤0.03% to minimize carbide precipitation during welding.

This material resists chloride-induced corrosion, making it ideal for marine engineering and chemical processing. Its smooth surface meets hygienic standards for pharmaceutical and food industries. The density of 8.0 g/cm³ ensures durability while maintaining structural efficiency.

Manufacturing involves welding and cold working, followed by solution annealing to enhance stress resistance. Rigorous quality checks—hydrostatic testing and ultrasonic inspection—ensure leak-proof performance. Available in outer diameters of 57–114 mm and wall thicknesses of 1.2–3.0 mm, it supports customized industrial applications.

Mechanical properties include tensile strength ≥485 MPa and yield strength ≥170 MPa, compliant with ASTM A249 standards. Surface treatments like acid cleaning improve cleanliness for sensitive applications.

EN10216-5 1.4404 Stainless Steel 316L Pipe

The EN10216-5 1.4404 stainless steel pipe (equivalent to 316L) is a low-carbon austenitic alloy designed for pressure applications under the EN10216-5 European standard, ensuring compliance with mechanical and corrosion-resistant requirements. Its composition includes chromium (16–18%), nickel (10–14%), molybdenum (2–3%), and ≤0.03% carbon, minimizing carbide precipitation during welding. The material’s density of 8.0 g/cm³ balances structural efficiency and durability.

This pipe exhibits high tensile strength (≥485 MPa) and yield strength (≥170 MPa), suitable for boilers, heat exchangers, and chemical processing systems45. Its resistance to chloride-induced corrosion makes it ideal for marine environments and medical equipment.

Manufacturing involves seamless or welded processes with cold working and solution annealing to optimize microstructure and stress resistance. Surface treatments like acid cleaning and bright annealing (BA) enhance hygienic performance for pharmaceutical and food industries.

Available in customized dimensions (OD: 57–114 mm; wall thickness: 1.2–3.0 mm), it supports diverse industrial needs while meeting EN10216-5’s rigorous quality controls.

JIS G3456 SUS316L Stainless Steel Pipe

The JIS G3459 SUS316L stainless steel pipe is a low-carbon austenitic alloy pipe standardized under the Japanese Industrial Standards (JIS), designed for industrial piping systems requiring corrosion resistance and mechanical reliability. Its composition includes chromium (16–18%), nickel (12–16%), molybdenum (2–3%), and carbon ≤0.03%, minimizing carbide precipitation during welding.

With tensile strength ≥520 MPa and yield strength ≥205 MPa, it withstands high-pressure and high-temperature environments, ideal for chemical processing and marine applications. The material’s density of 7.93–7.98 g/cm³ balances durability and lightweight design.

Manufactured through seamless or welded processes with solution annealing (≥1010°C rapid cooling), it ensures uniform microstructure and stress resistance. Hydrostatic and ultrasonic testing guarantee leak-proof performance and dimensional accuracy.

SUS316L excels in resisting chloride-induced corrosion and sensitization, making it suitable for welded components and harsh environments. Available in customizable dimensions, it meets JIS G3459’s strict specifications for industrial and commercial use.

GOST 994103X17H14M3/ 03X17H13M2 Stainless Steel Pipe 316L

The GOST 9941 03X17H14M3/03X17H13M2 stainless steel pipe (equivalent to 316L) is a low-carbon austenitic alloy designed for corrosion resistance in aggressive environments, compliant with Russian standards for seamless pipes. Its composition includes chromium (16–18%), nickel (12–14%), molybdenum (2–3%), and carbon ≤0.03%, ensuring minimal carbide precipitation during welding.

With a density of 8.0 g/cm³, it balances lightweight design and structural durability. The material exhibits tensile strength ≥520 MPa and yield strength ≥205 MPa, suitable for high-pressure applications in chemical, marine, and oil/gas industries.

Manufacturing involves cold drawing or seamless processes, followed by solution annealing (≥1010°C) to enhance stress corrosion resistance. Surface treatments like acid cleaning and bright annealing ensure hygienic performance for medical and food processing systems.

Available in diameters 8–159 mm and wall thickness 1–25 mm, it supports customized industrial requirements under GOST 9941 and GOST 5632 standard.

What Is SS316L Stainless Steel Pipe?

Firstly, the “SS” Means Stainless Steel in full spell.

The SS316L stainless steel pipe is a low-carbon austenitic alloy pipe known for exceptional corrosion resistance, widely used in chemical, marine, and food processing industries. Its composition includes chromium (16–18%), nickel (10–14%), molybdenum (2–3%), and carbon ≤0.03%, minimizing carbide precipitation during welding.

With a density of 7.93–7.98 g/cm³, it combines lightweight design with structural durability. The material delivers tensile strength ≥485 MPa and yield strength ≥170 MPa, suitable for high-pressure environments like heat exchangers and pharmaceutical systems.

Manufacturing involves cold rolling, solution annealing (≥1010°C), and pickling to enhance stress resistance and surface finish. Hydrostatic and ultrasonic testing ensure leak-proof performance and compliance with international standards34. Its resistance to chloride-induced corrosion makes it ideal for marine and medical applications.

KCM SPECIAL STEEL, ASTM A312/213 TP316L Stainless Steel Pipe RELATED PRODUCTS:

1. ASTM A312/213 TP 316L 316L Stainless Steel Pipe SEAMLESS

2. ASTM A312/213 TP316L 316L Stainless Steel Pipe WELDED

3. TP316L 316L Stainless Steel Pipe FITTINGS

4. TP316L 316L Stainless Steel PipeFLANGES

5. TP316L 316L Stainless Steel VALVES

ONE>ASTM A312/213 TP 316L 316L Stainless Steel Pipe SEAMLESS

1.SPECIFICATIONS:

| Standard: | AISI, ASTM, DIN,EN etc | Place of Origin: | Zhejiang, China | Brand Name: | KCM SPECIAL STEEL |

| Model Number: | Seamless Pipes/Tubes | Type: | TP316L Seamless pipes/Tubes | Steel Grade: | TP316/316L,SS316L,1.4404 |

| Application: | Heat exchanger and condenser, etc | Surface: | as customer’s required | Meterial: | austenitic stainless steel |

| Thickness: | SCH5~SCH160 | Outer Diameter: | 1/8″-48″ | Surface: | pickled & annealed |

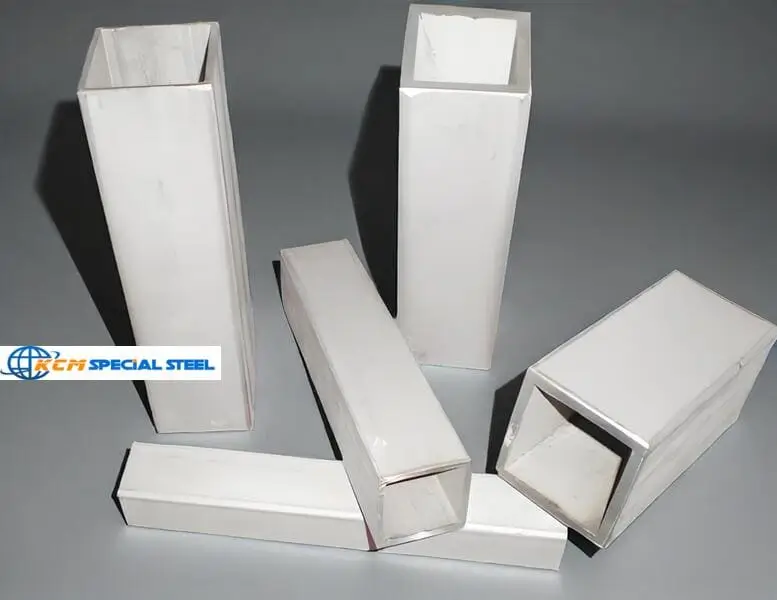

| Shape: | Round, Square, rectangular | Technique: | Cold finish | Length: | 16m max(fixed or random) |

| Payment terms: | T/T | Sample: | free | Delivery condition: | Pickled&annealed/polished |

| MOQ: | 500kgs | Packing: | as pe your request | inspection: | 100% |

2.ASTM A312/213 SS316L Stainless Steel Pipe SEAMLESS PACKING AND DELIVERY:

| Packaging Detail: | wooden cases or plastic by bundles as customer’s required |

| Delivery Detail: | 10- 30 days, there is also ready stock for your urgent project.

|

3.ASTM A312/213 AISI316L Stainless Steel Pipe SEAMLESS SURFACE:

SS 316L STAINLESS STEEL PIPE SUPPLIERS,MANUFACTURER,STOCKIST,CONTACT US FOR AMAZING PRICE AND HIGH QUALITY 316L STAINLESS STEEL PIPE.

4.ASTM A312/213 TP 316L 316L Stainless Steel Pipe SEAMLESS PRODUCTION PROCESS:

316L STAINLESS STEEL PIPE SEAMLESS PRODUCTION PROCESS, KCM SPECIAL STEEL IS SEAMLESS STAINLESS STEEL 316L PIPE SUPPLIER AND MANUFACTURER IN CHINA, CONTACT US FOR MORE DETAILS NOW!

5. ASTM A312/213 TP 316L Stainless Steel Pipe 316L SEAMLESS APPLICATIONS:

Ship Builders,

Automotive Industry,

Power Generation,

Food Industry,

Paper Industry,

ASTM A312/213 TP 316L 316L Stainless Steel Pipe SEAMLESS Use In Pharmaceutical Industry,

Chemical Industry,

Oil and Gas Industry,

Heat Exchanger

Chemical process vessels,

piping and heat exchangers

Pulp mill digesters,

bleach washers,

chip pre-steaming vessels

Food processing equipment

Oil field piping and heat exchangers

Flue gas desulfurization equipment

6. ASTM A312/213 TP 316L Stainless Steel Pipe SEAMLESS AVAILABLE SIZES IN STOCK:

| Dimensions for ASME/ANSI Standards | Unit:mm | ||||||||||||

| B16.9 B16.28 B36.10M | |||||||||||||

| Nominal pipe Size(NPS) | Outside Diameter | Nominal Wall Thickness | |||||||||||

| Sch5s | SCH10S | Sch20 | Sch30 | Sch40 | STD | Sch80 | XS | Sch160 | XXS | ||||

| 8 | 1/4 | 13.7 | 0.54 | – | 1.65 | – | 1.85 | 2.24 | 2.24 | 3.02 | 3.02 | – | – |

| 10 | 3/8 | 17.1 | 0.675 | – | 1.65 | – | 1.85 | 2.31 | 2.31 | 3.20 | 3.20 | – | – |

| 15 | 1/2 | 21.3 | 0.84 | 1.65 | 2.11 | – | 2.41 | 2.77 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 |

| 20 | 3/4 | 26.7 | 1.05 | 1.65 | 2.11 | – | 2.41 | 2.87 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 |

| 25 | 1 | 33.4 | 1.32 | 1.65 | 2.77 | – | 2.90 | 3.38 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 |

| 32 | 1.1/4 | 42.2 | 1.66 | 1.65 | 2.77 | – | 2.97 | 3.56 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 |

| 40 | 1.1/2 | 48.3 | 1.90 | 1.65 | 2.77 | – | 3.18 | 3.68 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 |

| 50 | 2 | 60.3 | 2.38 | 1.65 | 2.77 | – | 3.18 | 3.91 | 3.91 | 5.54 | 5.54 | 8.74 | 11.07 |

| 65 | 2.1/2 | 73.0 | 2.88 | 2.11 | 3.05 | – | 4.78 | 5.16 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 |

| 80 | 3 | 88.9 | 3.50 | 2.11 | 3.05 | – | 4.78 | 5.49 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 |

| 90 | 3.1/2 | 101.6 | 4.00 | 2.11 | 3.05 | – | 4.78 | 5.74 | 5.74 | 8.08 | 8.08 | – | – |

| 100 | 4 | 114.3 | 4.50 | 2.11 | 3.05 | – | 4.78 | 6.02 | 6.02 | 8.56 | 8.56 | 13.49 | 17.12 |

| 125 | 5 | 141.3 | 5.56 | 2.77 | 3.40 | – | – | 6.55 | 6.55 | 9.53 | 9.53 | 15.88 | 19.05 |

| 150 | 6 | 168.3 | 6.62 | 2.77 | 3.40 | – | – | 7.11 | 7.11 | 10.97 | 10.97 | 18.26 | 21.96 |

| 200 | 8 | 219.1 | 8.62 | 2.77 | 3.76 | 6.35 | 7.04 | 8.18 | 8.18 | 12.70 | 12.70 | 23.01 | 22.23 |

| 250 | 10 | 273.0 | 10.75 | 3.40 | 4.19 | 6.35 | 7.80 | 9.27 | 9.27 | 15.09 | 12.70 | 28.58 | 25.40 |

| 300 | 12 | 323.8 | 12.75 | 3.96 | 4.57 | 6.35 | 8.38 | 10.13 | 9.53 | 17.48 | 12.70 | 33.32 | 25.40 |

| 350 | 14 | 355.6 | 14 | 3.96 | 4.78 | 7.92 | 9.53 | 11.13 | 9.53 | 19.05 | 12.70 | 35.71 | – |

| 400 | 16 | 406.4 | 16 | 4.19 | 4.78 | 7.92 | 9.53 | 12.70 | 9.53 | 21.44 | 12.70 | 40.49 | – |

| 450 | 18 | 457 | 18 | 4.19 | 4.78 | 7.92 | 11.13 | 14.27 | 9.53 | 23.83 | 12.70 | 45.24 | – |

| 500 | 10 | 508 | 20 | 4.78 | 5.54 | 9.53 | 12.70 | 15.09 | 9.53 | 26.19 | 12.70 | 50.01 | – |

| 550 | 22 | 559 | 22 | 4.78 | 5.54 | 9.53 | 12.70 | – | 9.53 | 28.58 | 12.70 | 53.98 | – |

| 600 | 24 | 610 | 24 | 5.54 | 6.35 | 9.53 | 14.27 | 17.48 | 9.53 | 30.96 | 12.70 | 59.54 | – |

| 650 | *26 | 660 | 26 | – | – | – | – | – | 9.53 | – | 12.70 | – | – |

| 700 | *28 | 711 | 28 | – | – | – | – | – | 9.53 | – | 12.70 | – | – |

| 750 | *30 | 762 | 30 | – | – | – | – | – | 9.53 | – | 12.70 | – | – |

| 800 | *32 | 813 | 32 | – | – | – | – | – | 9.53 | – | 12.70 | – | – |

TWO>1.ASTM A312 TP 316L STAINLESS STEEL WELDED PIPE SPECIFICATIONS:

| Standard: | AISI, ASTM, DIN,EN etc | Place of Origin: | Zhejiang, China | Brand Name: | KCM SPECIAL STEEL |

| Model Number: weldedPipes/Tubes | Type: | TP316L welded pipes/Tubes | Steel Grade: | TP316/316L,SS316L,1.4404 | |

| Application: | Heat exchanger and condenser, etc | Surface: | as customer’s required | Meterial: | austenitic stainless steel |

| Thickness: | SCH5~40 | Outer Diameter: | 1/8″-48″ | Surface: | pickled & annealed |

| Shape: | Round, Square, rectangular | Technique: | Cold finish | Length: | 16m max(fixed or random) |

| Payment terms: | T/T | Sample: | free | Delivery condition: | Pickled&annealed/polished |

| MOQ: | 500kgs | Packing: | as pe your request | inspection: | 100% |

2.ASTM A312 TP 316L STAINLESS STEEL WELDED PIPE PACKING AND DELIVERY:PLASTIC BY BUNDLES OR WOODEN CASE OR ACC TO CUSTOMER REQUEST.

3.ASTM A312 TP 316L STAINLESS STEEL WELDED PIPE :

316L stainless steel welded pipe supplier and manufacturer in china, inquiry us now! to get high performance and good price of stainless steel 316L Pipe.

THREE> 316L Stainless Steel Pipe FITTINGS

- 316L STAINLESS STEEL PIPE FITTINGS SPECIFICATIONS:

Standard: AISI,DIN,EN etc Place of Origin: Zhejiang, China Brand Name: KCM SPECIAL STEEL Model Number: pipe fittings Type: TP316L pipefittings Steel Grade: TP316/316L,SS316L,1.4404 Application: shipbuilding and condenser, etc Surface: as customer’s required Meterial: austenitic stainless steel Thickness: SCH5~SCH160 Outer Diameter: 1/8″-48″ Surface: pickled&annealed Shape: elbow,Tee,reducer,stub end,cross,sw fittings. Technique: bend finish Length: standard Payment terms: T/T Sample: free Delivery condition: Pickled&annealed/polished MOQ: 500kgs Packing: as pe your request inspection: 100% 316L STAINLESS STEEL PIPE FITTINGS AVAILABLE SIZES IN STOCK.(ELBOW,TEE,REDUCER,CROSS)

Dimensions for ASME/ANSI Standards Unit:mm B16.9 B16.28 B36.10 Nominal pipe Size(NPS) Outside Diameter Nominal Wall Thickness Sch5s SCH10S Sch20 Sch30 Sch40 STD Sch80 XS Sch160 XXS 8 1/4 13.7 0.54 – 1.65 – 1.85 2.24 2.24 3.02 3.02 – – 10 3/8 17.1 0.675 – 1.65 – 1.85 2.31 2.31 3.20 3.20 – – 15 1/2 21.3 0.84 1.65 2.11 – 2.41 2.77 2.77 3.73 3.73 4.78 7.47 20 3/4 26.7 1.05 1.65 2.11 – 2.41 2.87 2.87 3.91 3.91 5.56 7.82 25 1 33.4 1.32 1.65 2.77 – 2.90 3.38 3.38 4.55 4.55 6.35 9.09 32 1.1/4 42.2 1.66 1.65 2.77 – 2.97 3.56 3.56 4.85 4.85 6.35 9.70 40 1.1/2 48.3 1.90 1.65 2.77 – 3.18 3.68 3.68 5.08 5.08 7.14 10.15 50 2 60.3 2.38 1.65 2.77 – 3.18 3.91 3.91 5.54 5.54 8.74 11.07 65 2.1/2 73.0 2.88 2.11 3.05 – 4.78 5.16 5.16 7.01 7.01 9.53 14.02 80 3 88.9 3.50 2.11 3.05 – 4.78 5.49 5.49 7.62 7.62 11.13 15.24 90 3.1/2 101.6 4.00 2.11 3.05 – 4.78 5.74 5.74 8.08 8.08 – – 100 4 114.3 4.50 2.11 3.05 – 4.78 6.02 6.02 8.56 8.56 13.49 17.12 125 5 141.3 5.56 2.77 3.40 – – 6.55 6.55 9.53 9.53 15.88 19.05 150 6 168.3 6.62 2.77 3.40 – – 7.11 7.11 10.97 10.97 18.26 21.96 200 8 219.1 8.62 2.77 3.76 6.35 7.04 8.18 8.18 12.70 12.70 23.01 22.23 250 10 273.0 10.75 3.40 4.19 6.35 7.80 9.27 9.27 15.09 12.70 28.58 25.40 300 12 323.8 12.75 3.96 4.57 6.35 8.38 10.13 9.53 17.48 12.70 33.32 25.40 3. 316L Stainless Steel Pipe FITTINGS SURFACE:

- (1) BW FITTINGS

- 3.(2) SW FITTINGS

316L STAINLESS STEEL PIPE FITTINGS SOCKET WELD TYPE MANUFACTURER AND SUPPLIER IN CHINA WITH HIGH QUALITY AND GOOD PRICE FOR INDUSTRAIL APPLICATIONS

- FOUR>

TP 316L 316L Stainless Steel Pipe FLANGES

FIVE> 316L STAINLESS STEEL VALVES

SS316L/TP316L/AISI316L/1.4404/316L Stainless Steel Pipe FAQ

Q1: What distinguishes 316L from standard 316 stainless steel pipes?

A: 316L has lower carbon content (≤0.03%), reducing weld decay risks in welded structures .

Q2: How long does 316L last in saltwater environments?

A: Oxidation rate <0.05mm/year under marine conditions, with a lifespan exceeding 20 years with maintenance .

Q3: How to calculate the required wall thickness for high-pressure applications?

A: Use formula P=2×S×t÷D S = allowable stress (80 MPa @ 600°C), t = thickness, D = outer diameter .

Q4: Are custom sizes and surface finishes available?

A: Yes, including polished (Ra≤0.8μm), pickled, or sandblasted finishes; non-standard sizes are supported .

Q5: What certifications should buyers request?

A: Mill Test Certificates (MTC), ASTM/ASME compliance reports, and third-party test data (e.g., SGS) .

Q6: Can You Supply 316L Stainless Steel Pipes Together with Pipe fittings, Flanges, and Valves?

A: Yes, KCM Special Steel Is One Stop Solution For 316L Pipes, Pipe Fittings, Flanges, and Valves.