Description

316 STAINLESS STEEL TUBING PIPE

316 Stainless Steel Tubing Pipe is A chromium-nickel-molybdenum austenitic alloy steel pipe (Cr 16–18%, Ni 10–14%, Mo 2–3%)3, optimized for superior corrosion resistance in chloride-rich environments (e.g., marine applications).

316 Stainless Steel Tube Pipe’s low-carbon variant (316L, ≤0.03% C) minimizes carbide precipitation during welding, ensuring stability in high-temperature (up to 870°C) and corrosive conditions. Widely used in petrochemical pipelines, marine equipment, medical devices, and food-grade systems. Complies with standards such as ASTM A312 and ASME SA213

VERY PORPULAR 316 STAINLESS STEEL TUBING PIPES IS WIDELY USE IN MANY INDUSTRIES’ AREAS, LET ME GIVE U SOME SUGGESTIONS FOR IT,

WE HAVE LARGE QTY OF 316 STAINLESS STEEL TUBING PIPES STOCK, IF YOU ARE INTERSTING, WE CAN SUPPORT UR URGENT PROJECT TIMELY AND QUALIFIED.

High Performance 316 stainless steel tubing pipe supplier & manufacturer in china, Contact KCM SPECIAL STEEL now! get discount price of stainless steel 316 tube.

ASTM A213 TP316 Stainless Steel Tubing Pipe: High-Performance Solution for Extreme Environments

Introduction

ASTM A213 TP 316 stainless steel tubing is a premium-grade material designed for high-temperature and high-pressure applications. Widely used in power plants, chemical processing, and heat exchangers, it combines superior corrosion resistance with mechanical durability35. This article explores its specifications, manufacturing, and applications.

ASTM A213 TP 316 stainless steel tubing pipe Supplier and Manufacturers in China, KCM SPECIAL STEEL always offer high performance and reasonalble price of stainless steel 316 tubing

316 Stainless Steel tube Material Specifications

Standard Compliance: Governed by ASTM A213/ASME SA-213M, TP 316 tubing ensures consistency in composition and performance.

Dimensional Tolerance: Strict wall thickness controls (-0% +20% of nominal) prevent failures under stress.

Grades: TP 316 and TP316L (low-carbon variant) cater to diverse thermal and corrosive environments.

Chemical Composition & Mechanical Properties

| Element | Composition (%) | Mechanical Properties | Value |

| Chromium | 16.0–18.0 | Tensile Strength | ≥520 MPa |

| Nickel | 10.0–14.0 | Yield Strength | ≥205 MPa |

| Molybdenum | 2.0–3.0 | Elongation | ≥40% |

| Carbon | ≤0.08 | Hardness | ≤200 HV |

316 Stainless Steel Tube Manufacturing Process

Forming: Seamless tubes are produced via hot extrusion or cold drawing to ensure structural integrity.

Heat Treatment: Solution annealing (1010–1150°C) optimizes corrosion resistance and ductility.

Testing: Hydrostatic, ultrasonic, and eddy-current inspections validate quality.

316 Stainless Steel Tube Applications

Power Generation: Superheaters and boilers in coal/nuclear plants.

Chemical Industry: Resistant to acids, chlorides, and sulfides in reactors.

Oil & Gas: Subsea pipelines and refinery components.

Summary

ASTM A213 TP316 stainless steel tube excels in extreme conditions due to its balanced alloy design and rigorous manufacturing standards. Its versatility across industries underscores its reliability for critical infrastructure.

FAQ

Q1: How does TP316 differ from TP316L?

A: TP316L has lower carbon content (≤0.03%), reducing carbide precipitation in welds.

Q2: What temperatures can TP316 withstand?

A: It performs reliably up to 870°C intermittently and 925°C continuously.

Q3: Are these tubes suitable for marine environments?

A: Yes, molybdenum enhances resistance to saltwater corrosion.

Q4: What certifications ensure quality?

A: Compliance with ASTM A213, ASME SA-213M, and EN 10216-5 guarantees performance.

TOP REMINDER OF ASTM A213 TP316 Stainless Steel Tube Pipe Wall Thickness Tolerance

General Tolerance

The wall thickness tolerance for ASTM A213 tp 316 seamless stainless steel tubing / tube is defined as -0% (minimum) to +20% (maximum) of the nominal thickness. This ensures the actual wall thickness never falls below the specified value but may exceed it by up to 20%.

TP316 Stainless Steel tube Key Specifications

Nominal Thickness Compliance:

The tube must meet the standard’s minimum wall thickness requirement without deviation below the nominal value.

Excess material (up to +20%) is permitted to accommodate manufacturing variability.

Critical Applications:

Strict adherence to the tolerance range ensures reliability in high-pressure and high-temperature environments, such as boilers and heat exchangers.

TP316 Stainless Steel Tube Example Calculation

| Nominal Thickness (mm) | Minimum Allowed (mm) | Maximum Allowed (mm) |

| 2.0 | 2.0 | 2.4 (+20%) |

| 5.0 | 5.0 | 6.0 (+20%) |

Summary

ASTM A213 TP 316 stainless steel tube / tubing mandates a -0/+20% tolerance for seamless tubing wall thickness. This balances manufacturing feasibility with performance integrity in critical industrial applications.

FAQ

Q1: Why is there no negative tolerance for wall thickness?

A: A minimum thickness guarantee ensures structural safety under pressure.

Q2: Does the +20% tolerance apply to all tubing sizes?

A: Yes, unless otherwise specified in supplementary standards (e.g., ASME).

Q3: How is compliance verified?

A: Manufacturers use ultrasonic or eddy-current testing to validate thickness

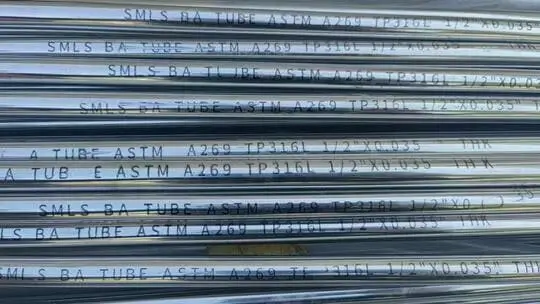

ASTM A269 TP 316 Stainless Steel Tubing Pipe: Advanced Corrosion Resistance with Enhanced Visual Insights

Introduction

ASTM A269 TP 316 stainless steel tubing offers superior corrosion resistance and mechanical stability for industries like pharmaceuticals, food processing, and chemical manufacturing. Its seamless and welded variants ensure compliance with stringent hygiene and durability standards.

ASTM A269 TP 316 Stainless Steel Tubing Pipe Supplier and Manufacturer in China, contact us for more details and get high performace stainless steel 316 tubing pipe price.

TP316 Stainless Steel Tubing Pipe Material Specifications

Standard Compliance: ASTM A269 governs seamless/welded austenitic tubing for general and high-purity services.

TP316 Stainless Steel tube Dimensional Range:

Outer Diameter: 3.2 mm to 101.6 mm.

Wall Thickness: 0.4 mm to 12.7 mm.

Grades: TP 316 (≤0.08% carbon) and TP316L (≤0.03% carbon) for improved weldability.

Chemical Composition & Mechanical Properties

| Element | Composition (%) | Mechanical Properties | Value |

| Chromium (Cr) | 16.0–18.0 | Tensile Strength | ≥515 MPa |

| Nickel (Ni) | 10.0–14.0 | Yield Strength | ≥205 MPa |

| Molybdenum (Mo) | 2.0–3.0 | Elongation | ≥40% |

| Carbon (C) | ≤0.08 | Hardness (HV) | ≤200 |

316 stainless steel tubing pipe Manufacturing Process

tp316 stainless steel tube Forming:

Seamless: Cold-drawn or hot-extruded for precision.

Welded: TIG/laser welding for sanitary joints.

Heat Treatment: Solution annealing (1050–1150°C) enhances corrosion resistance.

Surface Finishing:

Electropolishing: Reduces bacterial adhesion.

Passivation: Improves oxide layer stability.

316 stainless steel tube Applications & Performance

Pharmaceuticals: Sterile fluid transfer systems compliant with FDA standards.

Food & Beverage: Resists acidic cleaners (e.g., CIP/SIP processes).

Chemical Processing: Handles chlorides and sulfuric acid.

316 stainless steel tube Additional Charts

1. 316 stainless steel tube Temperature Resistance Profile

| Service Condition | Max Temperature |

| Continuous Operation | 870°C |

| Short-Term Exposure | 925°C |

| Cryogenic Applications | -196°C |

2. 316 stainless steel tube Surface Finish Options

| Finish | Ra (μm) | Application |

| Electropolished | ≤0.3 | High-purity fluid transfe |

| Pickled | ≤1.6 | General industrial use |

| BA (Bright Annealed) | ≤0.8 | Aesthetic and hygienic needs |

Summary

ASTM A269 TP316 stainless steel tubing pipe combines molybdenum-enhanced corrosion resistance, precise manufacturing, and versatile surface finishes. Its adaptability across high-stress environments makes it indispensable for critical industrial applications.

FAQ

Q1: What distinguishes TP316L from TP 316?

A: TP316L’s lower carbon content (≤0.03%) minimizes carbide precipitation during welding.

Q2: Can this 316 stainless steel tubing withstand seawater exposure?

A: Yes, molybdenum content provides excellent pitting resistance in chloride-rich environments.

Q3: Are custom surface finishes available?

A: Options include electropolished, pickled, or BA finishes for specific hygiene or aesthetic needs.

Q4: What quality controls ensure dimensional accuracy?

A: Ultrasonic testing and eddy-current inspections verify wall thickness (±10% tolerance)

ASTM A269 / ASTM A213 TP316/316L /316l/ 316 STAINLESS STEEL TUBE PIPE SPECIFICATIONS:

| Standard: | AISI, ASTM, DIN,EN etc | Place of Origin: | Zhejiang, China | Brand Name: | KCM SPECIAL STEEL |

| Model Number: | Seamless and welded Pipes/Tubes | Type: | TP316/316L Seamless and welded pipes/Tubing | Steel Grade: | TP316/316L |

| Application: | Heat exchanger and condenser, etc | Surface: | as customer’s required | Meterial: | austenitic stainless steel |

| Thickness: | SCH5~SCH160 | Outer Diameter: | 1/8″-48″ | Surface: | pickled&annealed |

| Shape: | Round,Square,rectangular | Technique: | Cold finish | Length: | 16m max(fixed or random) |

| Payment terms: | T/T | Sample: | free | Delivery condition: | Pickled&annealed/polished |

| MOQ: | 100kgs | Packing: | as pe your request | inspection: | 100% |

ASTM A213/269 TP 316 STAINLESS STEEL TUBING PIPE manufacturer / supplier PACKING&DELIVERY:

| Packaging Detail: | wooden cases or plastic by bundles as customer’s required |

| Delivery Detail: | 10- 30 days

|

Astm A213/269 TP 316 stainless steel tubing pipe seamless & welded

KCM special steel co.,ltd. The factory has the most professional laboratory with the well-equipped facilities, including Cold Rolling Machine, Eddy Current Test Machine, Impact Tester Equipment, Hydraulic Test Equipment, Handheld Spectrometer, etc. And visit Manufacturing Tubing video right here https://www.youtube.com/shorts/ngsdF3yR5TA

| Grade

| TP 304; TP304H; TP304L; TP316; TP316L; TP 321;TP321H; TP317L; TP310S; TP347H |

| Standard

| ASTM A213, ASTM A 269, ASTM A 270,EN10216-5; ASTM B 622;ASTM B516;ASTM A789, etc |

| Size | OD: 5.8-1219mm(0.23″-48″) |

| WT: 1-50.8mm(0.04″-2″) | |

| Length:Max.16M | |

| Advantage | Superior surface finish ,better mechanical property; more precise dimension; perfect inspection method and inspection equipment |

| Package | Plywood case; plastic by bundle |

NDT: Eddy Current or Hydraulic Test

Heat Treatment: Bright Annealed

Quality Assurance: KCM Special Steel is ISO 9001 & PED97/23/EC certified with 100% traceablity on all instrument Tube and material test reports (EN 10204/3.1B) accompany every shipment upon request.

ASTM A269/213 TP316/316L/316l/ 316 STAINLESS STEEL TUING PIPE MANFUACTURER APPLICATIONS:

a) General service industries

1. petroleum industry,

2.food industry,

3. chemical industry,

4.paper industry,

5. fertilizer industry,

6. fabric industry,

7. aviation industry,

8. nuclear industry

b) in Fluid,

2. gas transport

3. oil transport

c) 1. Pressure

2. heat transmission

d) 1. Construction

2. ornament

e) Boiler heat exchangers

f) Decorative usage

1. road lamp facilities,

2.bridge handrail

3.expressway railing,

4. bus stop,

5. airport

6. gymnasium

7. boiler

8. auto parts

9. medical equipment

10. building meterial

11.food industry.

ASTM A269/213 TP316L 316 STAINLESS STEEL SEAMLESS TUBING PIPE CHEMICAL&MECHANICAL

| Chemical Composition of Material | Material Composition | 201 | 202 | 304 | 316L | 430 |

| C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.035 | ≤0.12 | |

| Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

| Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | |

| P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | |

| S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | |

| Cr | 13-15 | 14-17 | 18-20 | 16-18 | 16-18 | |

| Ni | 0.7-1.1 | 3.5-4.5 | 8-10.5 | 10-14 | ||

| Mo | 2.0-3.0 | |||||

| Mechanical Property | Material Item | 201 | 202 | 304 | 316 | |

| Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | ||

| Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | ||

| Extension | ≥30% | ≥30% | ≥35% | ≥35% | ||

| Hardness (HV) | <105 | <100 | <90 | |||

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce pipes with special specifications according to customers’ requirements;

TP316L STAINLESS STEEL SEAMLESS PIPE is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids.

It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members.

TP316L SMLS pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable.

Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

Cases and Customer Feedbacks on 316 Stainless Steel Tubing

Case 1: Pharmaceutical Application of ASTM A269 TP316 Stainless Steel Tubing

Project Overview:

A renowned pharmaceutical company was in need of high-quality tubing for their sterile fluid transfer systems. The requirement was stringent, demanding tubing that could withstand the rigorous cleaning processes (CIP/SIP) and comply with FDA standards. After thorough research, they opted for ASTM A269 TP316 stainless steel tubing from KCM Special Steel Co., Ltd.

Solution Provided:

KCM Special Steel supplied seamless ASTM A269 TP316 stainless steel tubing, known for its superior corrosion resistance and mechanical stability. The tubing met the specified outer diameter range of 3.2 mm to 101.6 mm and wall thickness of 0.4 mm to 12.7 mm. Additionally, the electropolished surface finish reduced bacterial adhesion, ensuring the tubing was suitable for pharmaceutical applications.

Customer Feedback:

“We are extremely satisfied with the quality of ASTM A269 TP316 stainless steel tubing provided by KCM Special Steel. The tubing has exceeded our expectations in terms of durability and corrosion resistance. The electropolished finish has made maintenance easier and has significantly reduced the risk of contamination. Overall, it has enhanced the efficiency of our sterile fluid transfer systems.” – Head of Production, Pharmaceutical Company

Case 2: Oil & Gas Pipeline Upgrade with ASTM A213 TP316 Stainless Steel Tubing

Project Overview:

An international oil & gas company was upgrading their subsea pipelines due to increased corrosion rates in chloride-rich environments. They required tubing that could withstand high pressures, extreme temperatures, and provide long-term corrosion resistance. ASTM A213 TP316 stainless steel tubing from KCM Special Steel was chosen for its molybdenum-enhanced corrosion resistance and ability to perform reliably up to 870°C intermittently.

ASTM A213 TP316 Stainless Steel Tubing/tube Suppliers and manufacturers in China, discover high quality and discount price stainless steel 316 tube.

Solution Provided:

KCM Special Steel supplied seamless ASTM A213 TP316 stainless steel tubing with strict wall thickness controls (-0% +20% of nominal) to prevent failures under stress. The tubing’s low-carbon variant (316L) minimized carbide precipitation during welding, ensuring stability in high-temperature and corrosive conditions.

Customer Feedback:

“The ASTM A213 TP316 stainless steel tubing from KCM Special Steel has been a game-changer for our subsea pipeline project. The tubing has shown exceptional corrosion resistance in chloride-rich environments, and its ability to withstand high temperatures has been crucial. The seamless construction has provided additional strength and reliability, ensuring the safety of our operations. We highly recommend KCM Special Steel for any critical infrastructure projects.” – Project Manager, Oil & Gas Company

Case 3: Chemical Processing Plant Expansion with SS316 Tubing

Project Overview:

A chemical processing plant was expanding its facilities and needed tubing that could handle a variety of acids, chlorides, and sulfides in reactors. They required tubing that was not only corrosion-resistant but also met stringent dimensional and mechanical property standards. SS316 tubing from KCM Special Steel was chosen for its versatility and compliance with ASTM specifications.

Solution Provided:

KCM Special Steel supplied both seamless and welded SS316 tubing, compliant with ASTM A213 and ASTM A269 standards. The tubing was produced via hot extrusion or cold drawing for seamless variants and TIG/laser welding for welded variants, ensuring precision and structural integrity. The solution annealing process optimized corrosion resistance and ductility, making it suitable for chemical processing applications.

Customer Feedback:

“The SS316 tubing from KCM Special Steel has been a vital component in our chemical processing plant expansion. The tubing has shown remarkable resistance to acids, chlorides, and sulfides, ensuring the smooth operation of our reactors. The seamless and welded variants have provided flexibility in design and installation. The quality assurance and certifications provided by KCM Special Steel have given us peace of mind regarding the reliability and performance of the tubing.” – Chemical Engineer, Chemical Processing Plant

Additional Customer Feedbacks

Feedback from a Food Industry Client:

“We use stainless steel 316 tubing for our food processing equipment due to its resistance to acidic cleaners and ability to maintain hygiene standards. KCM Special Steel has consistently provided high-quality tubing that meets our strict requirements. The electropolished finish on the tubing has been a game-changer in reducing bacterial adhesion, ensuring the safety of our products.” – Quality Assurance Manager, Food Industry

Feedback from a Power Plant Engineer:

“In our power plant, we rely on ASTM A213 TP316 stainless steel tubing for superheaters and boilers. The tubing’s ability to withstand high temperatures and pressures is crucial for our operations. KCM Special Steel has provided us with reliable and durable tubing that has significantly reduced downtime and maintenance costs. The company’s customer service and technical support have been invaluable in addressing any issues we’ve encountered.” – Power Plant Engineer

In conclusion, KCM Special Steel Co., Ltd. has established itself as a leading supplier of 316 stainless steel tubing, providing high-quality solutions for a wide range of industries. The company’s commitment to quality assurance, certifications, and customer satisfaction has made it the preferred choice for critical infrastructure projects worldwide.

TP316L 316 STAINLESS STEEL PIPE TUBING MANUFACTURER, MARKING & PACKING

While marking we choose a specific item number as well different color shade to differentiate steel grades. We mark TP316L stainless steel seamless pipe(manufacturer) as needed with the most suitable & visible marking technique.

Packaging is an integral part of the product. It guarantees that the TP316L SMLS pipe is delivered to the customer in the required quality.

For smaller orders the size of the TP316L stainless steel seamless pipe manufacturer bundle depends on the no. of Tubes ordered, for larger orders the tubes are packed into individual bundles and in such a way that the maximum weight of 4000kg per bundle is not excedded.

Bundle tied down with steel tape.

Bundle tied down by steel strap underlaid by tapaten.

We can also provide TP316L stainless steel seamless pipe manufacturer wooden box packing, cardboard boxes, plastic wrapping, using hardened paper with PE meshing (used as protection against mechanical damages of tubes), into tapaten and polyethylene sheet etc.

Where you can find the high quality TP316L STAINLESS STEELSEAMLESS PIPE.(manufacturer

You can visit this website:www.www.duplexstainlesssteelpipes.com (kcm special steel co.,ltd)