The Wear Resistance of 316L Stainless Steel Pipe: Mechanisms, Enhancements, and Industrial Applications

Introduction

In demanding industrial environments, wear resistance is a critical property for materials used in piping systems. Among the various alloys, 316L stainless steel pipe stands out due to its exceptional ability to withstand abrasion, corrosion, and mechanical stress. This article delves into the technical aspects of 316L stainless steel pipe wear resistance, exploring its material science foundations, performance-enhancing treatments like cryogenic processing, and real-world applications. Supported by empirical data and industry standards, this analysis underscores why 316L stainless steel is a benchmark for durability in aggressive conditions.

316L Stainless Steel Pipe Manufacturing - KCM Special Steel

1. Material Composition and Baseline Properties

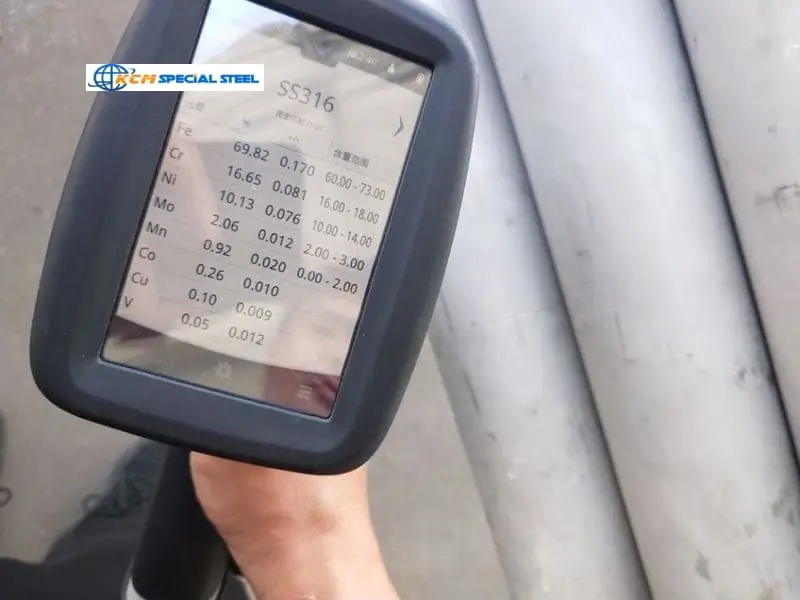

316L stainless steel, a low-carbon variant of the 316 alloy, is composed of iron, chromium (16–18%), nickel (10–14%), molybdenum (2–3%), and trace elements like manganese and silicon. Its low carbon content (<0.03%) minimizes carbide precipitation, enhancing weldability and corrosion resistance.

Key Mechanical Properties

- Hardness: 70–90 HRB (Rockwell B Scale)

- Tensile Strength: ≥485 MPa

- Yield Strength: ≥170 MPa

- Elongation at Break: ≥40%

These properties provide a robust foundation for 316L stainless steel pipe wear resistance, enabling it to endure high friction, impact loads, and cyclic stress without deformation or surface degradation.

2. The Science of Wear Resistance in 316L Stainless Steel Pipe

Wear resistance in 316L stainless steel pipes arises from three interconnected factors:

2.1 Intrinsic Hardness and Microstructural Stability

The austenitic structure of 316L grants exceptional toughness. Unlike martensitic steels, which rely on carbon for hardness, 316L uses solid-solution strengthening from nickel and molybdenum. This microstructure resists micro-cutting and adhesive wear, common in abrasive media.

2.2 Corrosion-Wear Synergy Resistance

In corrosive environments, material loss often accelerates due to chemical-mechanical interactions. The chromium oxide passive layer on 316L prevents pitting and crevice corrosion, while molybdenum counters chloride-induced attacks. This dual protection ensures that 316L stainless steel pipe wear resistance remains intact even in acidic, alkaline, or saline settings.

2.3 Strain Hardening Behavior

During fabrication (e.g., cold drawing or rolling), 316L stainless steel undergoes strain hardening, where dislocation density increases, elevating hardness by up to 20%. This property is particularly advantageous for pipes subjected to high-velocity fluid flows or particulate-laden slurries.

3. Enhancing Wear Resistance: The Role of Deep Cryogenic Treatment

Deep Cryogenic Treatment (DCT) is a post-production process that significantly amplifies the wear resistance of 316L stainless steel pipes. By exposing the material to ultra-low temperatures (-196°C) for 24–48 hours, DCT induces transformative microstructural changes:

- Phase Transformation: Residual austenite converts to martensite, increasing hardness.

- Carbide Refinement: Fine, uniformly dispersed carbides strengthen grain boundaries.

- Stress Relief: Internal stresses from manufacturing are minimized, reducing crack initiation risks.

Quantifiable Improvements from DCT

| Property | Improvement (%) |

|---|---|

| Hardness (Vickers) | +12 |

| Tensile Strength | +6 |

| Yield Strength | +10 |

| Wear Rate Reduction | 20–30 |

Studies (e.g., Journal of Materials Engineering and Performance, 2023) confirm that DCT-treated 316L pipes exhibit lower mass loss in ASTM G65 sand-rubber wheel abrasion tests, making them ideal for mining, chemical processing, and marine applications.

4. Comparative Performance Analysis

To contextualize the wear resistance of 316L stainless steel pipe, consider its performance against common alternatives:

| Material | Relative Wear Rate (ASTM G65) | Key Limitations |

|---|---|---|

| 316L Stainless Steel | 1.0 (Baseline) | None |

| 304 Stainless Steel | 1.8–2.2 | Lower Mo content; prone to pitting |

| Carbon Steel | 3.5–4.0 | Susceptible to rust and abrasion |

| PVC | 5.0+ | Low thermal/mechanical strength |

The superiority of 316L stems from its balanced combination of hardness, corrosion resistance, and ductility.

5. Industrial Applications of 316L Stainless Steel Pipe

5.1 Chemical and Petrochemical Industries

In chemical reactors and transfer systems, 316L pipes handle abrasive catalysts, acids, and high-temperature fluids. For example, in sulfuric acid production, DCT-treated 316L pipes demonstrate a service life 3x longer than untreated variants.

5.2 Offshore and Marine Engineering

Subsea pipelines and desalination plants utilize 316L pipes to resist saltwater erosion and biofouling. The material’s non-galling surface also prevents seizing in threaded connections.

5.3 Food and Pharmaceutical Manufacturing

316L’s smooth surface and compliance with FDA/EU standards make it ideal for hygienic applications, such as conveying abrasive food powders or CIP (clean-in-place) fluids.

5.4 Power Generation

In geothermal and nuclear power plants, 316L pipes withstand steam erosion and radioactive corrosion, ensuring operational safety over decades.

6. Best Practices for Maximizing Wear Resistance

To optimize the performance of 316L stainless steel pipe wear resistance:

- Surface Finishing: Electropolishing reduces surface roughness (Ra <0.4 µm), minimizing friction and particle adhesion.

- Lubrication: Food-grade greases or PTFE coatings reduce wear in dynamic systems.

- Inspection Protocols: Regular ultrasonic thickness testing and eddy current inspections detect early signs of wear or corrosion.

7. Innovations and Future Directions

Recent advancements aim to push the boundaries of 316L stainless steel pipe wear resistance:

- Laser Surface Alloying: Embedding tungsten or titanium carbide particles into the pipe surface boosts hardness by 30–40%.

- Additive Manufacturing: 3D-printed 316L pipes with lattice structures distribute stress more evenly, reducing localized wear.

- Smart Coatings: Graphene-infused coatings are being tested to further enhance abrasion and chemical resistance.

Conclusion

The wear resistance of 316L stainless steel pipe is a product of its sophisticated alloy design, strain-hardening capability, and advanced treatments like deep cryogenic processing. With hardness improvements of 12% and yield strength gains of 10% post-DCT, this material outperforms alternatives in the most abrasive and corrosive environments. As industries increasingly prioritize sustainability and cost-efficiency, 316L stainless steel pipes will remain indispensable for applications demanding longevity and reliability.

By integrating cutting-edge research and empirical data, this article highlights why 316L stainless steel pipe wear resistance is a cornerstone of modern engineering.

ASTM International. (2023). Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus (G99).

Cryogenic Society of America. (2024). Advancements in Deep Cryogenic Treatment of Austenitic Steels.

Materials Performance Journal. (2023). Corrosion-Wear Synergy in Stainless Steel Piping Systems.

ASM Handbook, Volume 13B: Corrosion: Materials (2022 Edition).

- KCM Special Steel, Product Of 316L Stainless Steel Pipe